Improved structure strong wind tempering furnace for steel belt heat treatment

A tempering furnace and steel strip technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of unstable input of protective atmosphere, unstable processing quality, and easy deformation of processed products, and achieve stable input of protective atmosphere and high processing quality The effect of stability and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

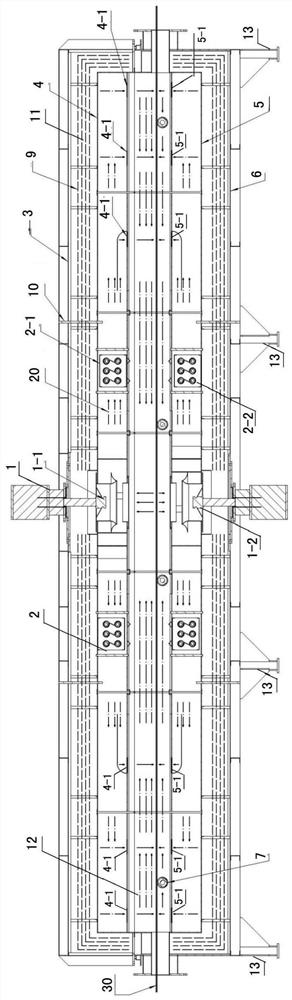

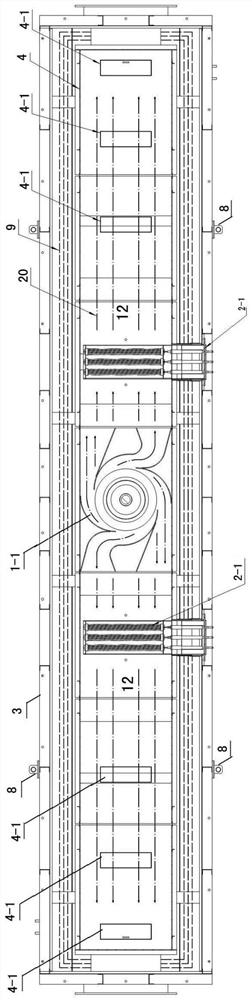

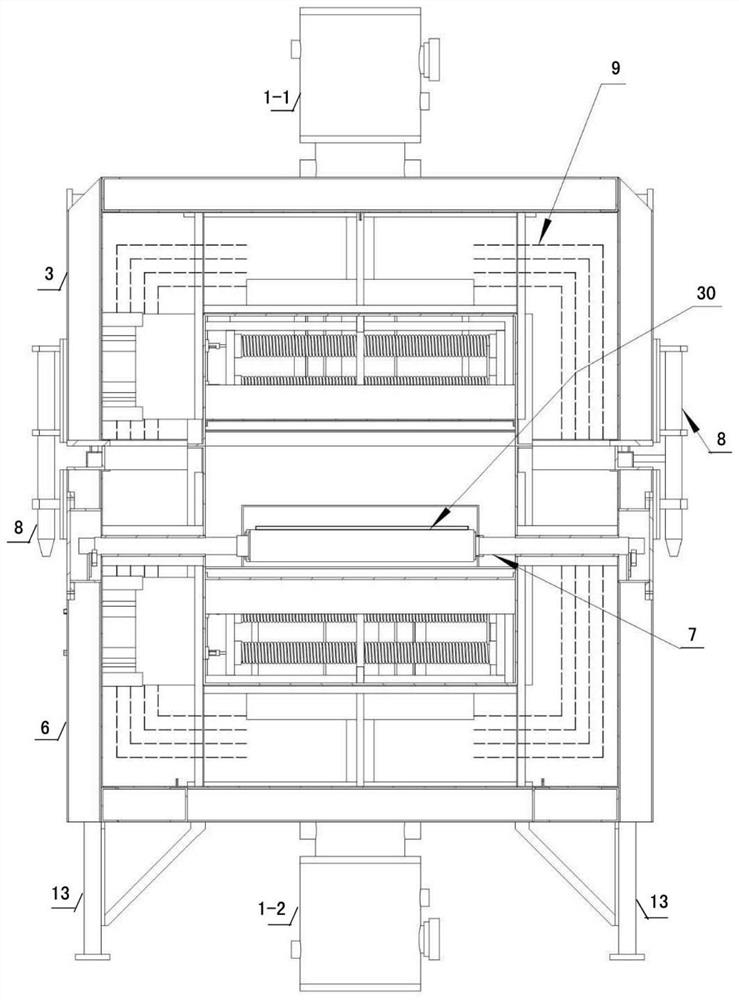

[0026] refer to Figure 1 to Figure 5 , the improved structure strong wind tempering furnace for steel strip heat treatment related to specific embodiment 1 of the present invention comprises a furnace body 6 and a furnace cover 3, and the furnace body 6 and the furnace cover 3 are joined to form a sealed inner cavity; at both ends of the joint There is a workpiece inlet / outlet, and the middle of the sealed inner cavity is a workpiece processing channel; a water-cooled fan 1 and a heating box 2 are arranged in the sealed inner cavity; an upper lining box 4 is arranged in the inner cavity of the furnace cover 3, and The furnace body 6 inner cavity is provided with a lower lining box 5, the upper lining box 4 is above the workpiece processing channel, and the lower lining box 5 is below the workpiece processing channel, forming a closed structure for the workpiece processing channel; 4 The bottom surface and the top surface of the lower lining box 5 are respectively provided wit...

specific Embodiment 2

[0044] The characteristics of the specific embodiment 2 of the present invention are: on the basis of the specific embodiment 1, according to the needs of the length of the furnace body and the processed product, the upper vent 4-1 arranged on the bottom surface of the upper lining box 4 can be four, There are eight, ten or more than twelve, and the lower vent 5-1 arranged on the top surface of the lower liner box 5 can be four, eight, ten or more than twelve, and the upper vent 4-1 is connected with the lower vent 5-1. The number of vents 5-1 is the same. All the other are with specific embodiment 1.

specific Embodiment 3

[0046] The characteristic of Embodiment 3 of the present invention is that the arrangement of several thermocouple tubes 10 in the annular airflow channel 11 is omitted. All the other are with specific embodiment 1 or specific embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com