Horizontally-opposed U-shaped low-vibration thermomotor transmission mechanism and thermomotor

A horizontally opposed, transmission mechanism technology, which is applied to hot gas variable displacement engine devices, machines/engines, engine components, etc., can solve the problems of large vibration and noise, large main bearing force, etc., to reduce the force and improve the torque balance performance, the effect of reducing amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

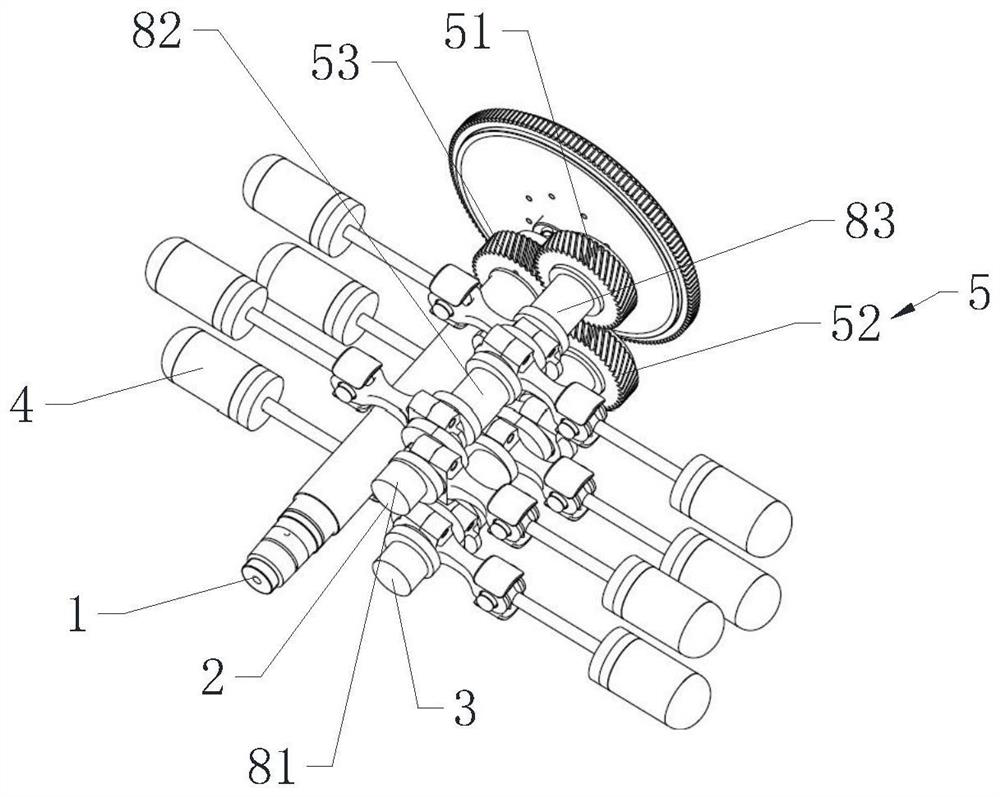

[0032] Reference manual attached Figure 1 to Figure 4 , the present invention provides a horizontally opposed U-shaped low-vibration heat engine transmission mechanism. The horizontally opposed U-shaped low-vibration heat engine transmission mechanism can solve the problems of large main bearing force and large vibration noise of the traditional heat engine transmission mechanism, and at the same time It can also reduce the number of main bearings, lower the center of gravity of the whole machine, and meet the needs of high-power, multi-cylinder heat engines.

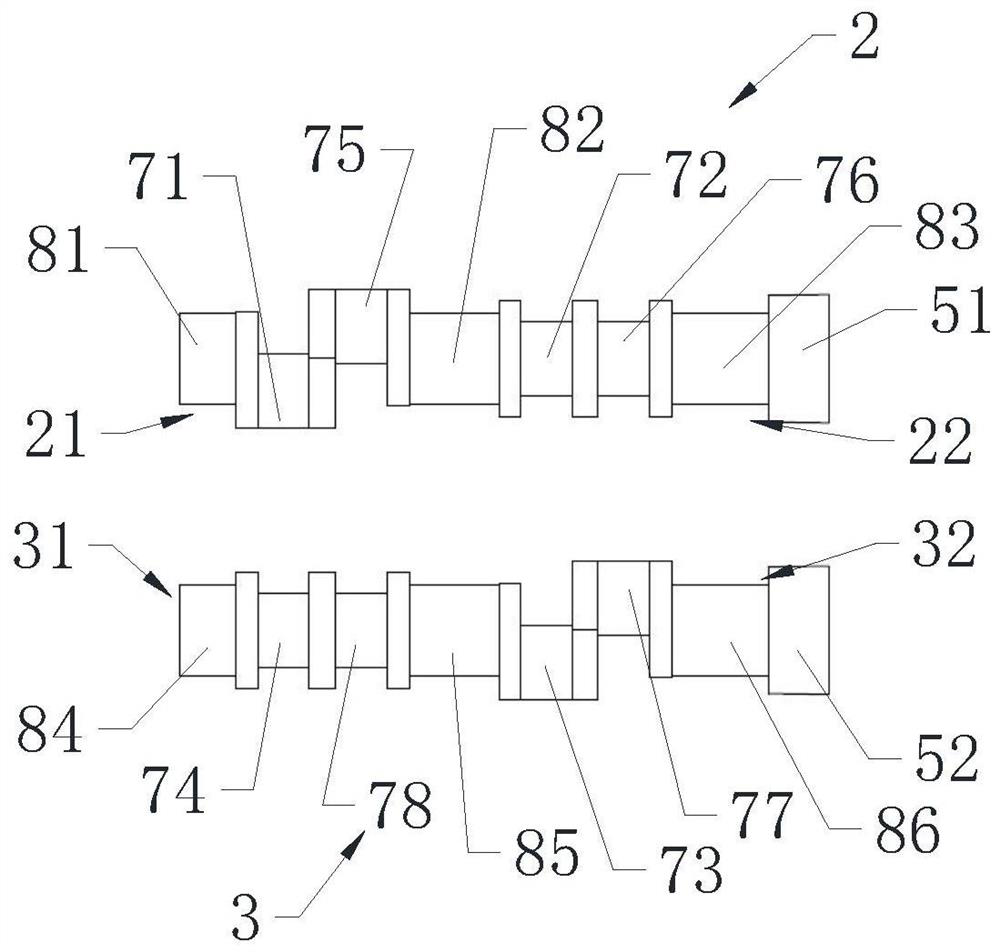

[0033] Reference manual attached figure 1 , the horizontally opposed U-shaped low-vibration heat engine transmission mechanism includes: an output shaft 1 , a first crankshaft 2 , a second crankshaft 3 , a piston rod connecting rod assembly 4 and a gear assembly 5 .

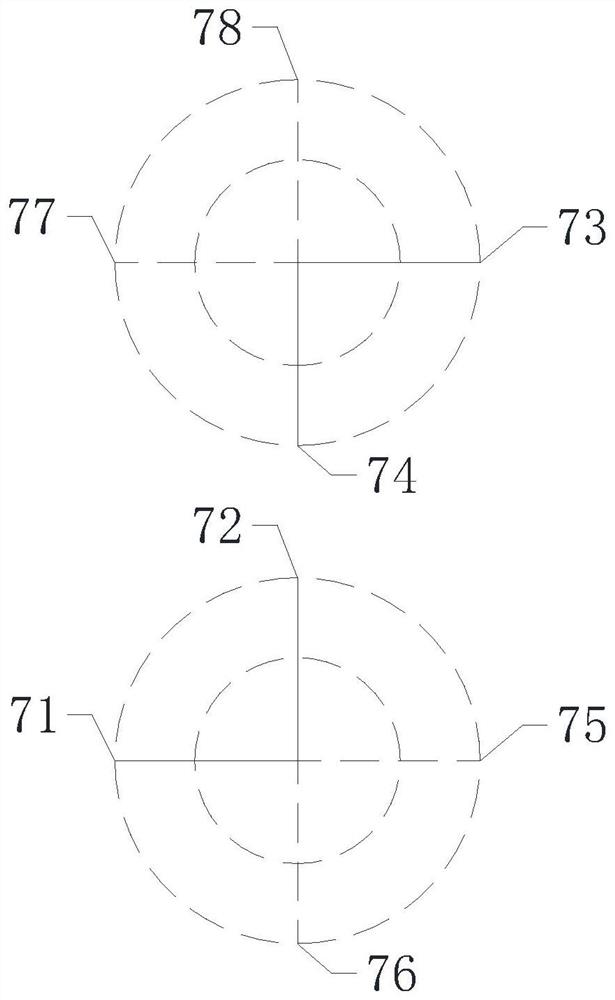

[0034] The first crankshaft 2 has a first free end 21 and a first output end 22, between the first free end 21 and the first output end 22 there are seq...

Embodiment 2

[0045] According to another aspect of the present invention, the present invention further provides a heat engine, which includes the horizontally opposed U-shaped low-vibration heat engine transmission mechanism described in Embodiment 1 above.

[0046] It should be pointed out that the heat engines can be combined into sixteen-cylinder, twenty-four-cylinder and other multi-cylinder heat engines with higher power as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com