Method for detecting mechanical strength of heat-treated wood

A technology of mechanical strength and detection method, which is applied in the field of non-destructive testing of mechanical strength of heat-treated wood, and the detection of mechanical strength of heat-treated wood, can solve problems such as damage to wood samples, loss of mechanical strength of wood, and large amount of repeated samples.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

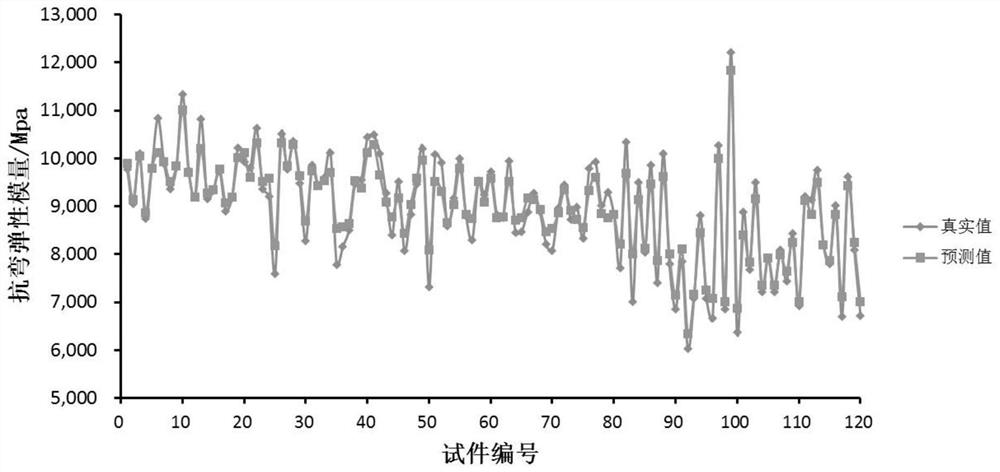

[0061] A poplar tomentosa specimen with a size of 20mm(R)×100mm(T)×390mm(L) was selected, nitrogen was used as a protective gas, the heat treatment temperatures were 180°C, 200°C and 220°C, and the heat treatment time was 2h and 4h respectively , 6h, 8h, 10h, select 10 pieces of wood for each group, select 9 points on the surface of the specimen after heat treatment, use visible light spectrophotometer to measure CIE (1976) L*, a*, b* value, and take the average of the measurement results value.

[0062] Finally, process each heat treatment specimen with a size of 20mm(R)×100mm(T)×390mm(L) into two test pieces with a size of 20mm(R)×20mm(T)×300mm(L), refer to the national The standard GB / T1936.2-2009 "Test method for flexural modulus of elasticity of wood" measures the flexural modulus of elastic modulus of treated wood, and takes the average value of the measurement results. The color parameters and flexural modulus of each group are trained and learned by the support vector...

Embodiment 2

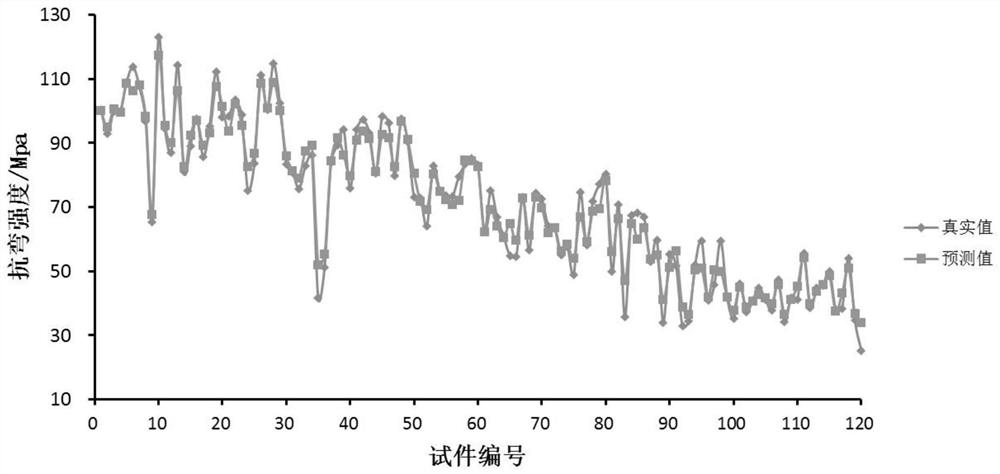

[0064] A poplar tomentosa specimen with a size of 20mm(R)×100mm(T)×390mm(L) was selected, nitrogen was used as a protective gas, the heat treatment temperatures were 180°C, 200°C and 220°C, and the heat treatment time was 2h and 4h respectively , 6h, 8h, 10h, select 10 pieces of wood for each group, select 9 points on the surface of the specimen after heat treatment, use visible light spectrophotometer to measure CIE (1976) L*, a*, b* value, and take the average of the measurement results value.

[0065] Finally, process each heat treatment specimen with a size of 20mm(R)×100mm(T)×390mm(L) into two test pieces with a size of 20mm(R)×20mm(T)×300mm(L), refer to the national The standard GB / T1936.1-2009 "Test method for flexural strength of wood" measures the flexural strength of treated wood, and the measurement results are averaged. Use the support vector machine model to train and learn the color parameters and bending strength of each group, and then substitute the color par...

Embodiment 3

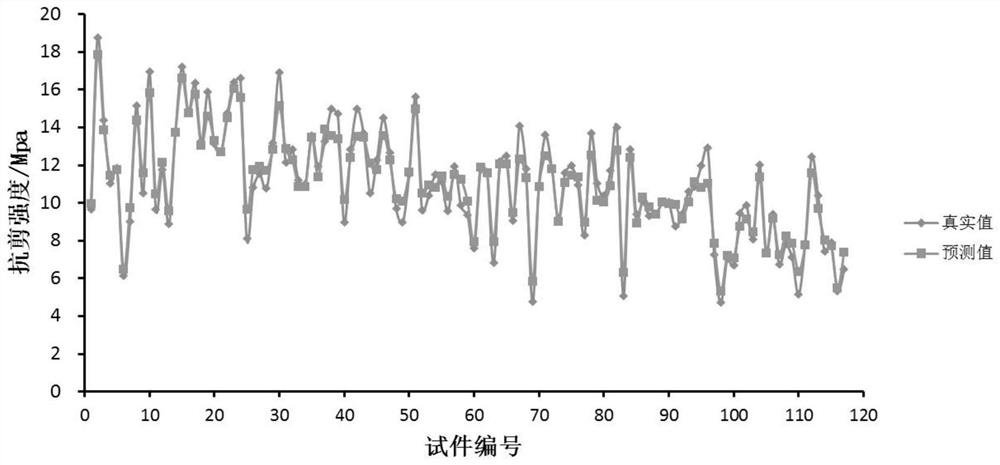

[0067] A poplar tomentosa specimen with a size of 20mm(R)×100mm(T)×390mm(L) was selected, nitrogen was used as a protective gas, the heat treatment temperatures were 180°C, 200°C and 220°C, and the heat treatment time was 2h and 4h respectively , 6h, 8h, 10h, select 10 pieces of wood for each group, select 9 points on the surface of the specimen after heat treatment, use visible light spectrophotometer to measure CIE (1976) L*, a*, b* value, and take the average of the measurement results value.

[0068] Finally, each heat-treated specimen with a size of 20mm(R)×100mm(T)×390mm(L) is processed into two right-angled trapezoidal specimens with upper and lower bottoms of 30mm and 40mm respectively, referring to the national standard GB / T 1937- 2009 "Test Method for Shear Strength of Timber Along the Grain" Measure the shear strength of the treated wood, and take the average value of the measurement results. The color parameters and shear strength of each group are trained and lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com