Impact type detection device for durability of intelligently-manufactured glass

A technology for intelligent manufacturing and testing devices, applied in the direction of measuring devices, strength characteristics, instruments, etc., can solve problems such as time-consuming and labor-consuming, inaccurate detection results, etc., to reduce manpower consumption, prevent swinging and hurt people, and reduce troubles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

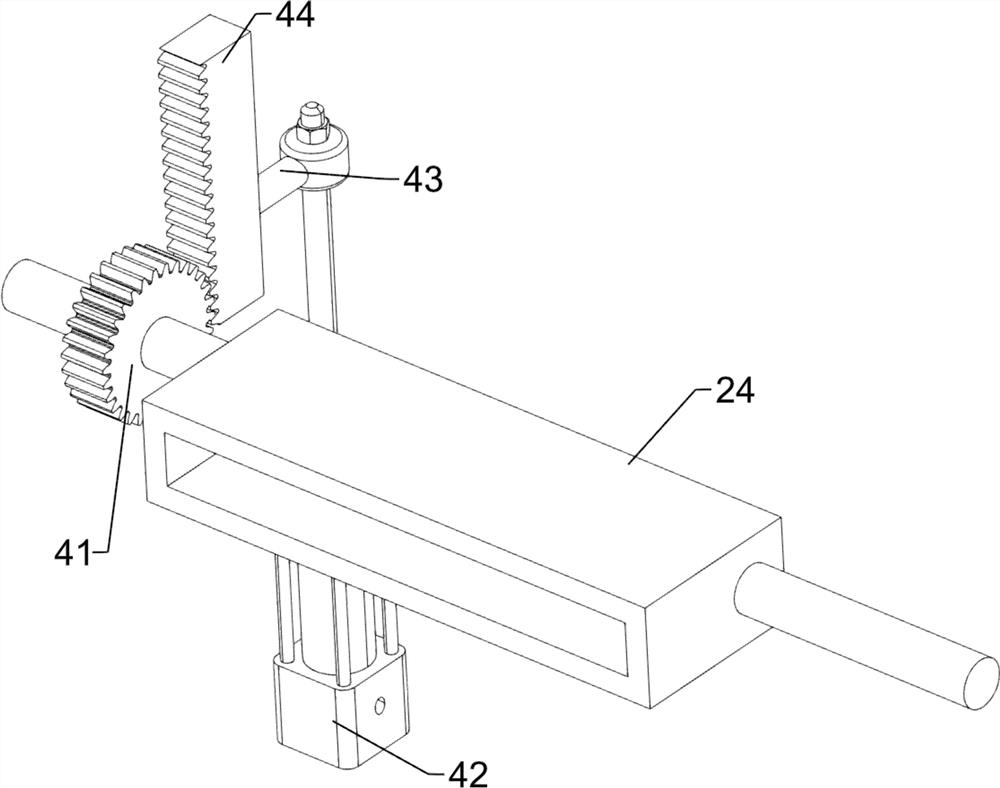

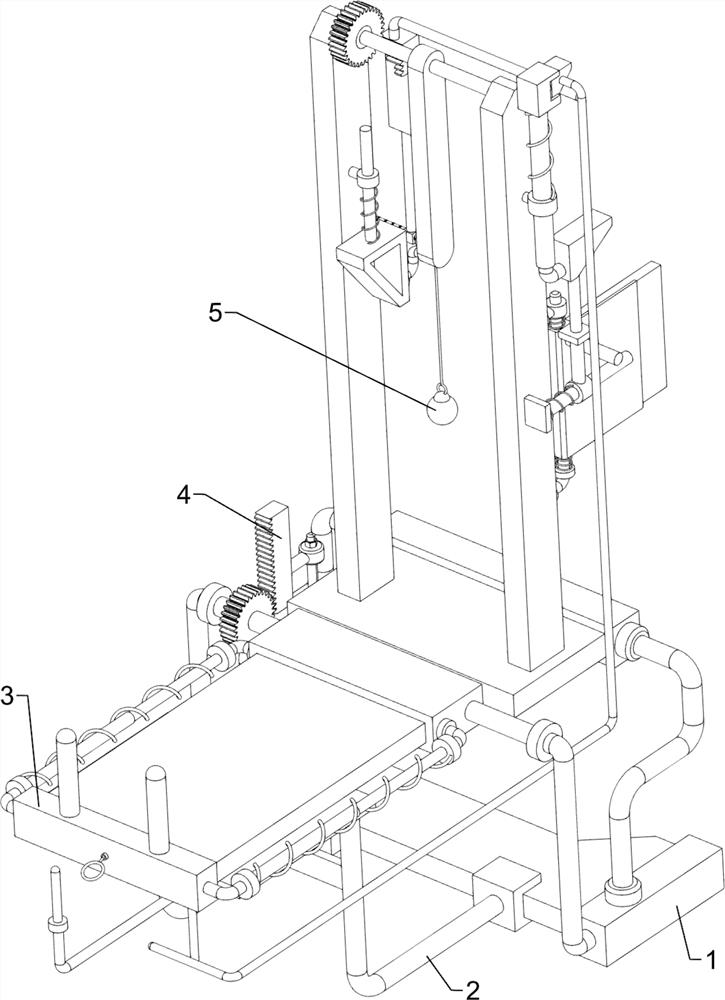

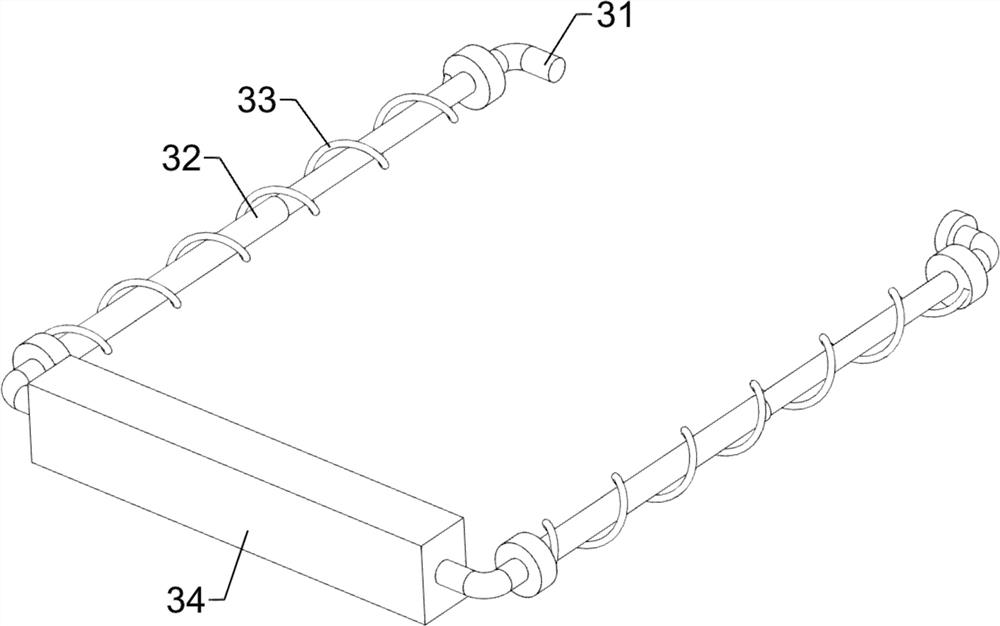

[0029] An intelligent manufacturing glass durability impact detection device, such as Figure 1-5 As shown, it includes a frame 1, a placement component 2, a clamping component 3, a rotating component 4 and a test component 5. The front side of the frame 1 is provided with a placement component 2, and the placement component 2 is provided with a clamping component 3. A rotating assembly 4 is provided between the frame 1 and the placing assembly 2 , and a testing assembly 5 is provided on the upper side of the frame 1 .

[0030] When it is necessary to perform a durability impact test on the intelligent manufacturing glass, the clamping component 3 is controlled, and the intelligent manufacturing glass is placed on the placement component 2, and then the clamping component 3 will clamp the glass, and then the rotating component 4 can be controlled. operation, and then make the placement component 2 and the clamping component 3 rotate, so that the glass is rotated and erected, a...

Embodiment 2

[0040] On the basis of Example 1, such as Image 6 , Figure 7 with Figure 8 As shown, it also includes a first contact rod 6, a pull ring 7 and a pull rod 8. The front side of the first connecting frame 21 is connected with the first contact rod 6, and the front side of the splint 34 is rotatably connected with a pull ring 7, and the pull ring 7 cooperates with the first contact rod 6, and the upper left and right sides of the splint 34 are connected with pull rods 8.

[0041] When it is necessary to place smart glass, the pull ring 7 can be pulled to move to the front side, and the splint 34 can be pulled to move to the front side, and then the pull ring 7 can be buckled on the first contact rod 6, so that the user does not need to pull the pull ring 7 all the time. The ring 7 is convenient for the user to place the glass. After the placement is completed, the control pull ring 7 is no longer in contact with the first contact rod 6, and the pull ring 7 is no longer contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com