Externally-attached portable electromagnetic induction flow pattern sensor and method for monitoring boiling two-phase flow pattern in heat exchange tube

An electromagnetic induction and sensor technology, applied in the field of digital sensors, can solve problems such as difficult monitoring and early warning, heat transfer deterioration, etc., and achieve the effects of low cost, strong practicability, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

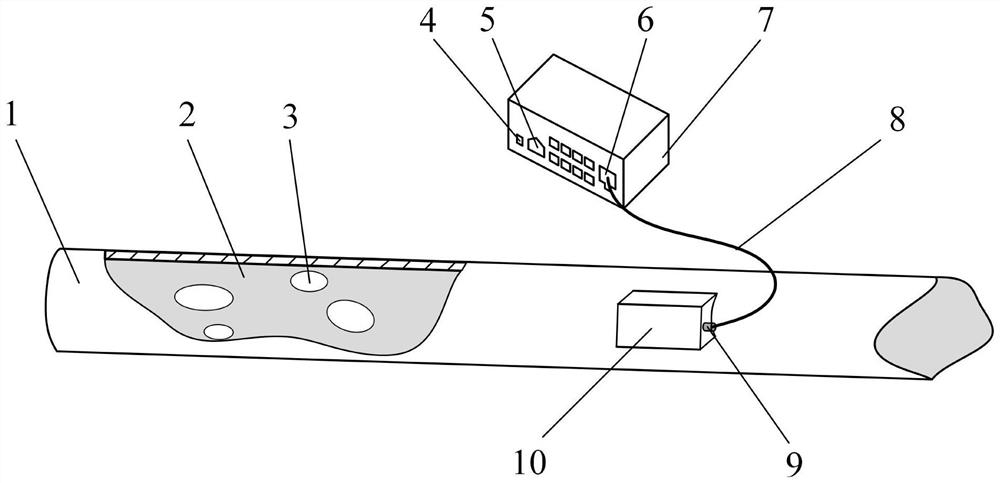

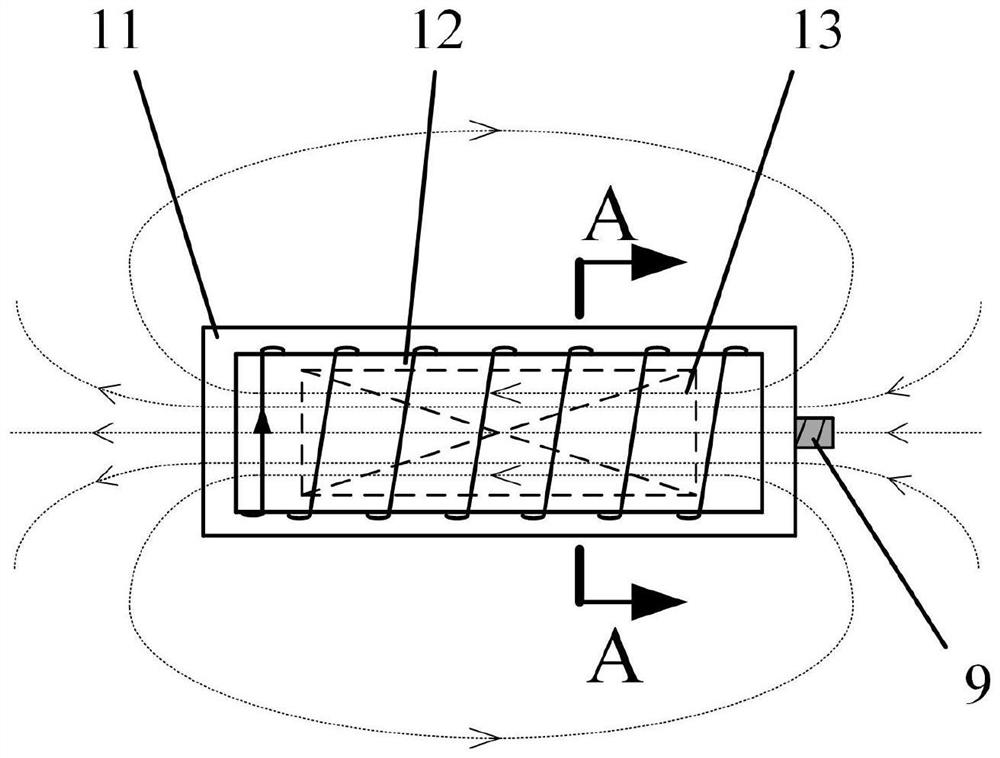

[0037] Embodiment 1: as figure 1 and 2 As shown, an externally attached portable electromagnetic induction flow sensor includes an electromagnetic induction sensor 10 and a host 7. The electromagnetic induction sensor 10 is externally attached to the surface of the heat exchange tube 1 to be tested and aligned with the horizontal axis of the heat exchange tube 1 to be tested. In parallel, the electromagnetic induction sensor 10 includes an energized solenoid 12 and an induction coil 13, the induction coil 13 is arranged in the middle part of the inner side of the energized solenoid 12, and the energized solenoid 12 and the induction coil 13 are all connected to the host computer 7;

[0038]After the DC excitation signal is added to both ends of the energized solenoid 12, a magnetic field is formed inside and outside the energized solenoid 12, and a Gauss meter can be used to measure the size of the external magnetic field of the energized solenoid 12. When the heat transfer to...

Embodiment 2

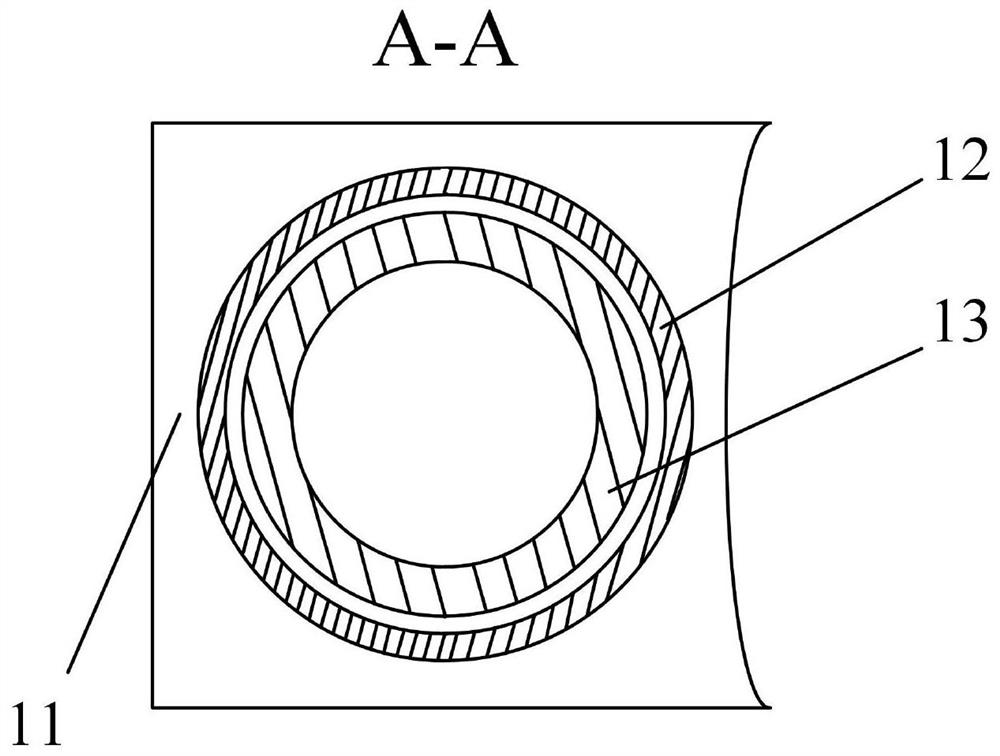

[0045] Embodiment 2: The externally pasted portable electromagnetic induction flow sensor of this embodiment is basically the same as the externally pasted portable electromagnetic induction flow sensor of Embodiment 1, the difference is that: figure 2 and 3 As shown, the electromagnetic induction sensor 10 also includes a protective shell 11, the energized solenoid 12 is arranged in the protective shell 11, and the side end of the protective shell 11 is provided with a data transmission port 9, and the energized solenoid 12 and the induction coil 13 are all connected to the data transmission The port 9 is connected, and the data transmission port 9 is connected with the host computer 7 through the signal cable 8;

[0046] The electrified solenoid 12 is formed by winding a copper core enameled wire, the number of turns is 2000-2500 turns, the length is 40-50mm, and the diameter of the copper core is 0.21-0.25mm;

[0047] The distance between the end of the energized solenoid...

Embodiment 3

[0049] Embodiment 3: The externally pasted portable electromagnetic induction flow sensor of this embodiment is basically the same as the externally pasted portable electromagnetic induction flow sensor of Embodiment 2, the difference is that: Figure 4 As shown, the load circuit of the host computer 7 includes an energized solenoid load circuit and an induction coil load circuit. The energized solenoid load circuit is connected to the energized solenoid 12 through the signal cable 8 and the data transmission port 9 in turn, and the induction coil load circuit is sequentially connected to the energized solenoid load circuit. Connect with the induction coil 13 through the signal cable 8 and the data transmission port 9;

[0050] The energized solenoid load circuit includes a nickel metal hydride battery, a power switch, an external power switch and an external DC stabilized power supply. The positive terminal of the nickel metal hydride battery is electrically connected with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com