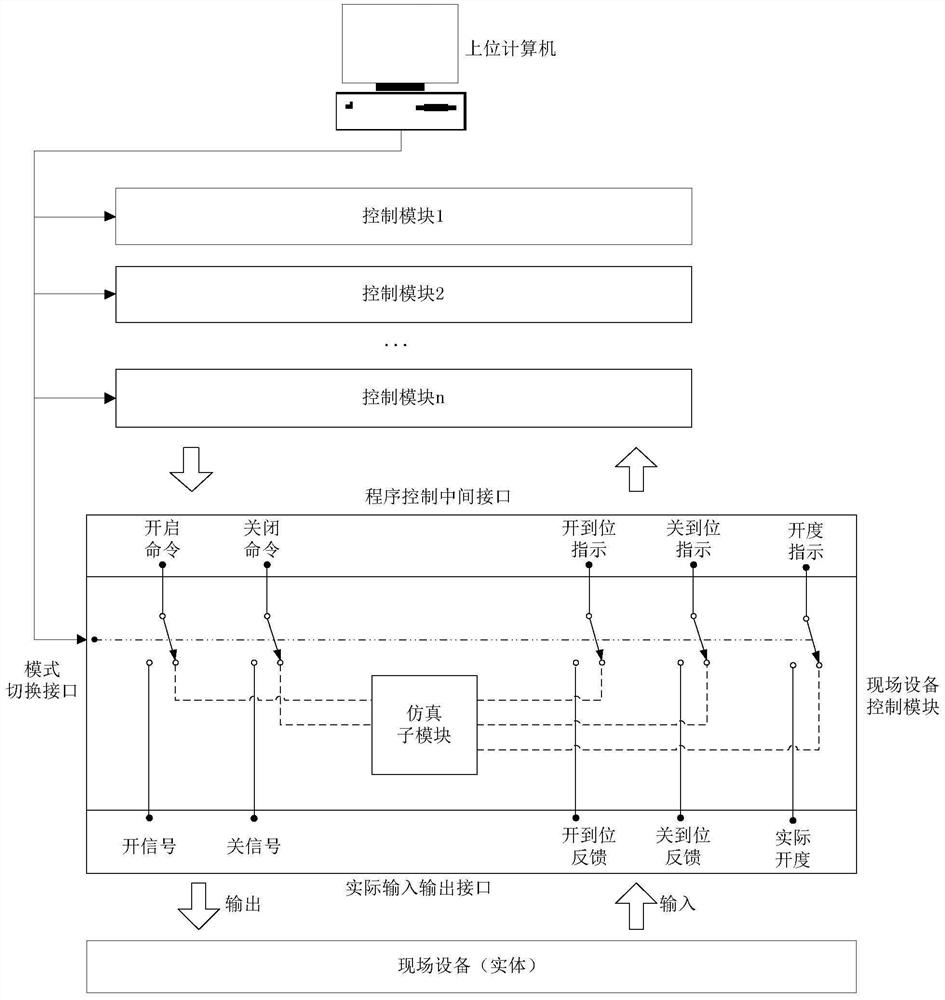

A wind tunnel test process verification method integrating practical operation and simulation

A technology of wind tunnel test and verification method, applied in the field of wind tunnel test, which can solve problems such as explosion, waste of manpower and material resources, damage of wind tunnel equipment, etc., to achieve the effect of ensuring safety and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]This embodiment is an application example of a high ultrasound speed. The specific situation is as follows: The newly modified test process requires T = 0 seconds to turn on the throttle valve; T = 1 second, turn on the main valve; T = 3 seconds, perform the valve bit judgment, if the main valve is fully turned on, and the adjustment valve is opened The degree is greater than 60%, then transfer to the liquid oxygen filling process, otherwise transfer to the emergency stop operation process. The wind tunnel control program is currently in the actual state, the main valve and throttling are closed. According to the data given by the valve manufacturer, the throttle valve is fully open for 4 seconds, and the valve bit is increased by time, and the main valve open valve time is 1.85 seconds. The simulation process of the test process includes the following steps:

[0041]a. The operator sets the throttle valve through the upper computer to 4 seconds, and the main valve opening valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com