Tool management console, system and method based on rfid tag identification

A RFID tag and tool management technology, applied in the field of tool management consoles based on RFID tag identification, can solve the problems of single-function warehouse tool consoles, inability to realize the operation consoles as they are installed and used, and the inability to realize rapid identification of tools, etc., to achieve Improve the efficiency of warehouse entry and exit, save the overall space, and improve the effect of safety control level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

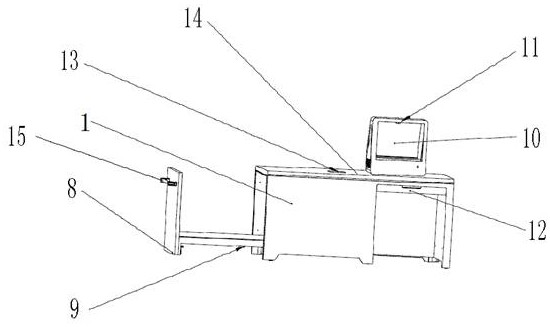

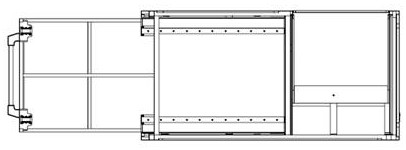

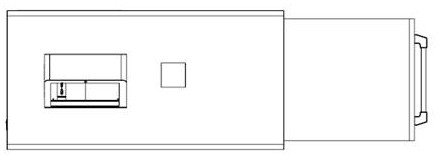

[0064] Embodiment 1 of the present invention provides a tool management console, including a console body 1, an RFID identification box is connected to the side of the console body, an RFID radio frequency identification module is fixed in the RFID identification box, and at least one of the RFID identification boxes side opening.

[0065] The upper surface of the console body is provided with a processor, and the processor is communicatively connected with the RFID radio frequency identification module.

[0066] In this embodiment, the processor is a computer terminal with a display screen 10, and the computer terminal communicates with the RFID radio frequency identification module, and a camera 11 for face recognition is also provided on the upper side of the display screen of the computer terminal.

[0067] It can be understood that in some other embodiments, the RFID radio frequency identification module adopts the SE-Mo2003-00 module, and the processor adopts the single-...

Embodiment 2

[0076] Embodiment 2 of the present invention provides a tool management console, including a console body, an RFID identification box is connected to the side of the console body, an RFID radio frequency identification module is fixed in the RFID identification box, and at least one side of the RFID identification box Open your mouth.

[0077] The upper surface of the console body is provided with a processor, and the processor is communicatively connected with the RFID radio frequency identification module.

[0078] In this embodiment, the processor is a computer terminal with a display screen, and the computer terminal communicates with the RFID radio frequency identification module.

[0079] It can be understood that in some other embodiments, the RFID radio frequency identification module adopts the SE-Mo2003-00 module, and the processor adopts the single-chip microcomputer AT89S51, and the AT89S51 is connected with a keyboard and a liquid crystal display circuit (OCMJ4*8C...

Embodiment 3

[0088] Embodiment 3 of the present invention provides a tool management console, including a console body, an RFID identification box is connected to the side of the console body, an RFID radio frequency identification module is fixed in the RFID identification box, and at least one side of the RFID identification box Open your mouth.

[0089] The upper surface of the console body is provided with a processor, and the processor is communicatively connected with the RFID radio frequency identification module.

[0090] In this embodiment, the processor is a computer terminal with a display screen, and the computer terminal communicates with the RFID radio frequency identification module.

[0091] It can be understood that in some other embodiments, the RFID radio frequency identification module adopts the SE-Mo2003-00 module, and the processor adopts the single-chip microcomputer AT89S51, and the AT89S51 is connected with a keyboard and a liquid crystal display circuit (OCMJ4*8C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com