Accident chlorine treatment device used in liquid chlorine production process

A production process and processing device technology, applied in the direction of gas treatment, cleaning methods and appliances, smoke and dust removal, etc., can solve problems such as difficult chlorine gas, harmless treatment, personnel and environmental hazards, so as to avoid secondary accidents and save costs , good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

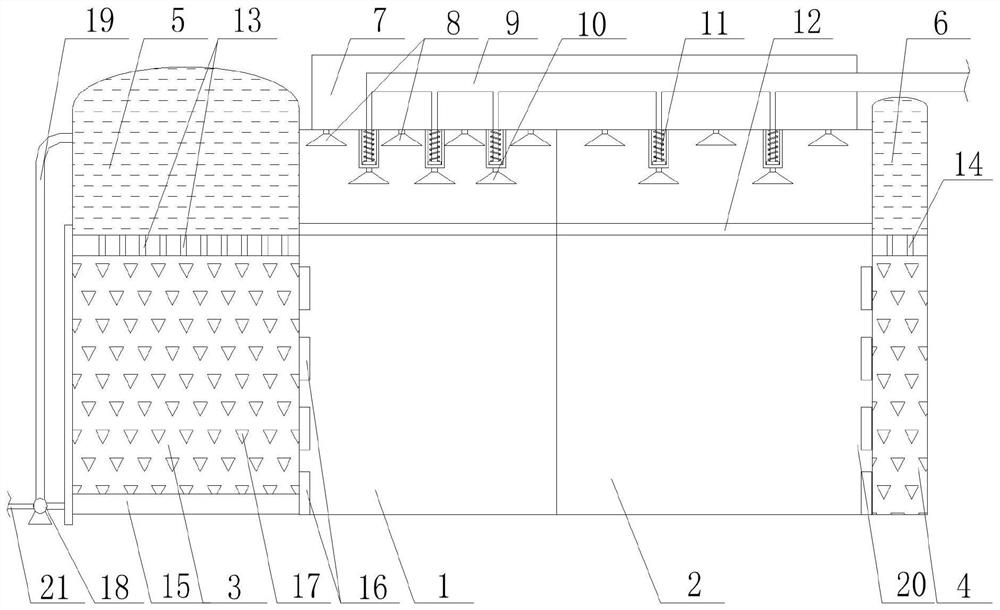

[0023] like figure 1 As shown, an accidental chlorine treatment device used in the liquid chlorine production process includes a liquid chlorine packaging plant 1 and a liquid chlorine storage tank plant 2, and the side of the liquid chlorine packaging plant 1 is provided with a packaging plant accidental chlorine treatment tower 3 , the side of the liquid chlorine storage tank factory building 2 is provided with a liquid chlorine storage tank factory building accident chlorine treatment tower 4, the top of the liquid chlorine packaging factory building 1 and the liquid chlorine storage tank factory building 2 is provided with a water tank 7, and the liquid chlorine storage tank factory building 2 is provided with a water tank 7. The tops of the packaging workshop 1 and the liquid chlorine storage tank workshop 2 are provided with a sprinkler head 8 and a wind collection hood 10, and a telescopic bellows 11 is connected to the wind collection hood 10, and the telescopic bellows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com