Rice processing and conveying device

A conveying device and rice processing technology, applied in conveyors, transportation and packaging, solid separation, etc., can solve the problems of increased processing costs, poor screening effect, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

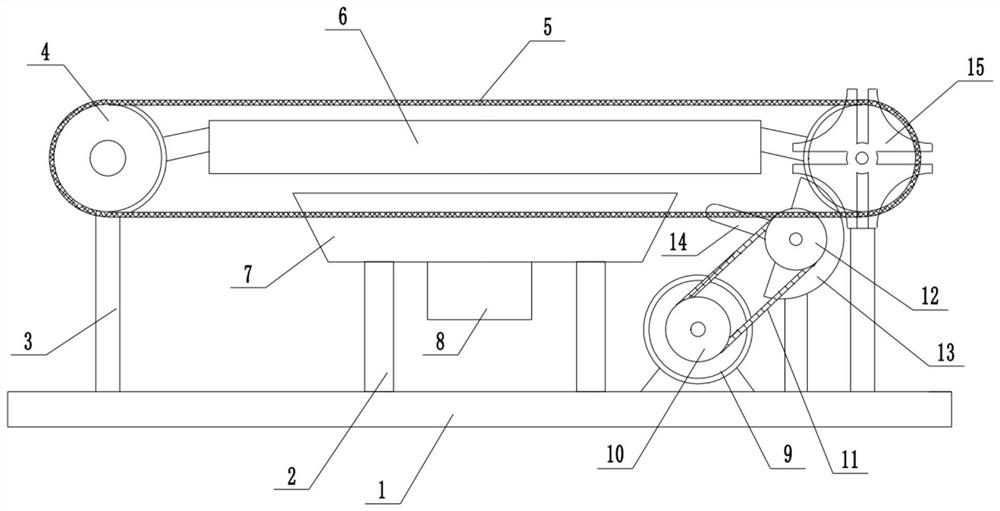

[0029] refer to Figure 1~4 , in an embodiment of the present invention, a rice processing and conveying device includes a fixed bottom plate 1, a support frame 3 is installed on both sides of the upper end of the fixed bottom plate 1, a transmission roller 4 is installed on the top of the support frame 3, and the transmission roller 4 on the right side is The front end is coaxially equipped with a driven disc 15, the left side of the lower end of the driven disc 15 is equipped with a driving disc 13, and the middle part of the driving disc 13 is coaxially equipped with a driven pulley 12, and the outer side of the driven pulley 12 passes through the belt 11 Connected with the driving pulley 10, the driving pulley 10 is connected with the output shaft of the driving motor 9, the driving motor 9 is fixed on the fixed base plate 1, and is used to drive the driving pulley 10 to rotate, thereby realizing the synchronous drive for the driving disc 13 The active rod 14 is installed ...

Embodiment 2

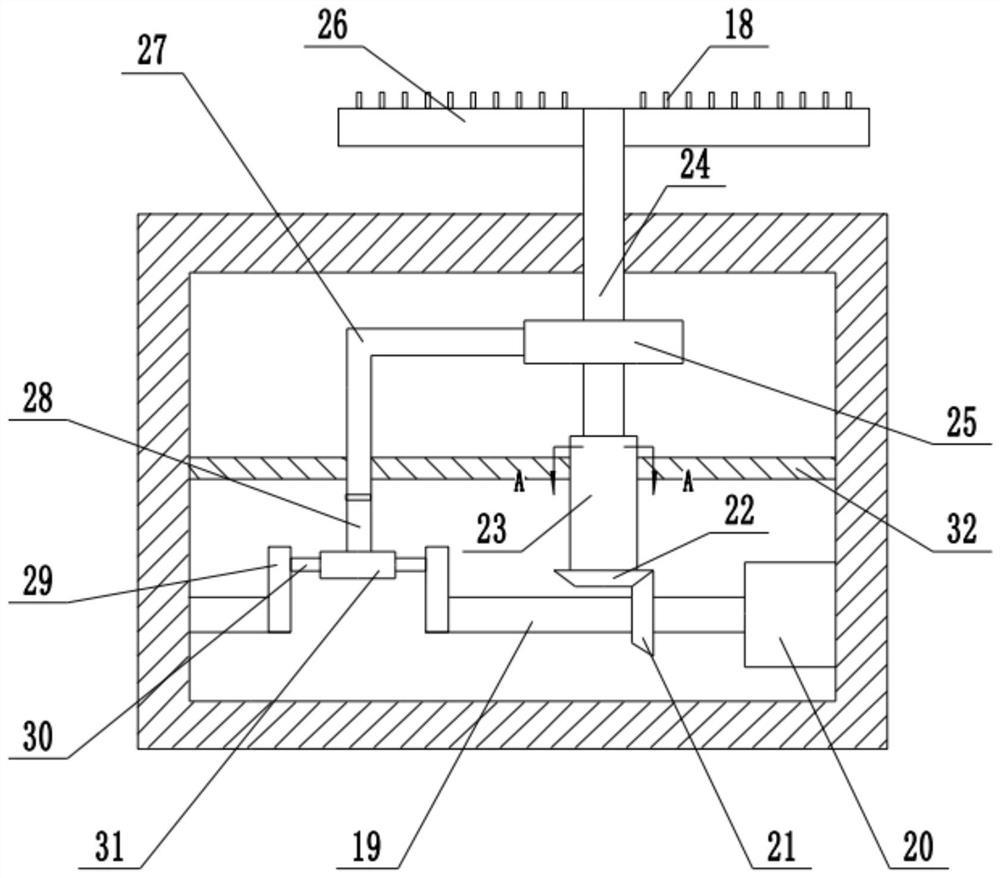

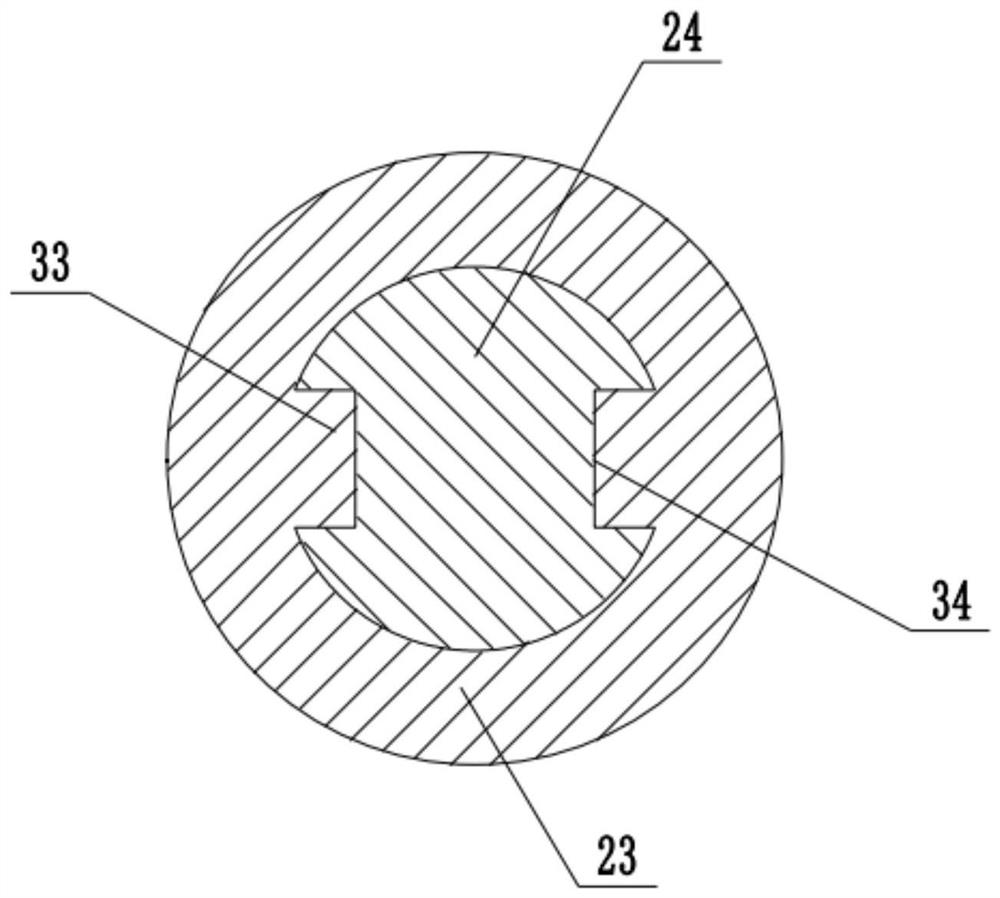

[0031]In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that a baffle 32 is installed between the inner walls of the blanking box 8, and the middle part of the right end of the baffle 32 is connected with a rotating shaft through a bearing. 23, thereby ensuring that the rotating shaft 23 does not shake in a large range during the rotation process, and the middle part on the left side of the baffle plate 32 is provided with a perforation that cooperates with the swing rod 27 to limit and guide the up and down movement of the swing rod 27.

[0032] In the present invention, during work, the rice that needs to be conveyed is placed on the left side of the conveyor belt 5, and then the active motor 9 is started, and the active motor 9 will drive the active disc 13 to rotate, and then under the cooperation of the linear portion 16 and the active rod 14, The driven belt 15 drives the transmission roller 4 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com