Automatic numerical control lathe

A CNC lathe and automatic technology, applied in the field of CNC lathes, can solve the problems of insufficient cleaning of debris, inconvenient collection of metal scraps, and insufficient comprehensiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

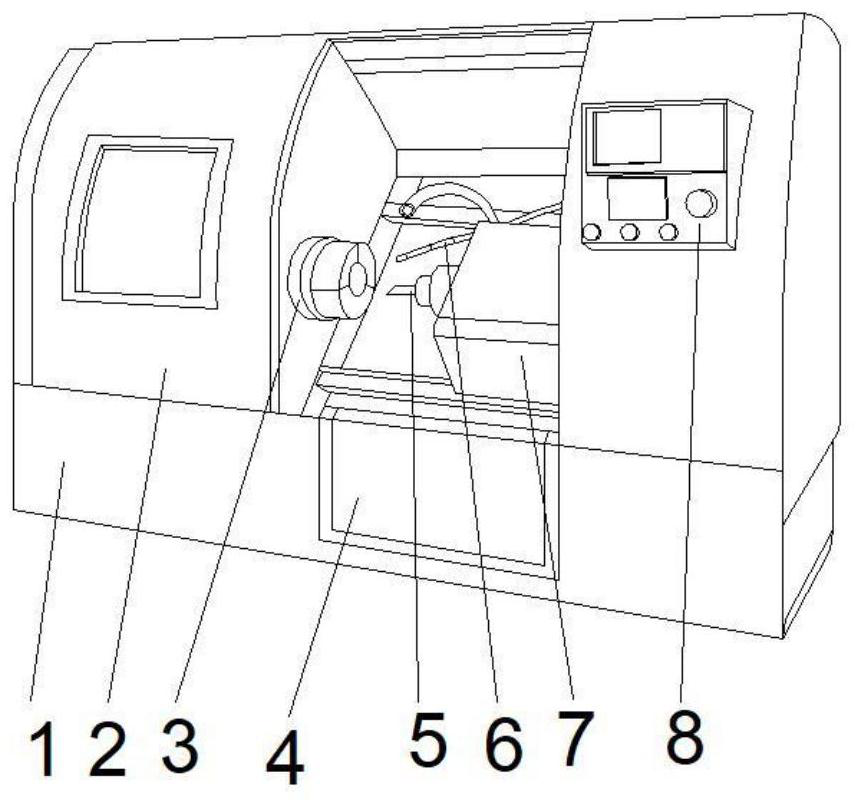

[0035] Such as Figure 1-2 , a technical solution proposed by the present invention: an automatic numerically controlled lathe, comprising a main body 1, a protective door 2 is fixedly connected to the left side of the front top of the main body 1, and a feeding device 3 is provided at the middle position on the left side of the inner cavity of the main body 1, and the feeding device 3 is The left end of the device 3 runs through the main body 1, and the middle position on the right side of the inner cavity of the main body 1 is provided with a moving mechanism 7. The middle position on the left side of the moving mechanism 7 is fixedly connected with a cutter 5, and the top right side of the moving mechanism 7 is fixedly connected with a cooling pipe 6. A collection device 4 is provided at the middle of the bottom of the inner cavity of the main body 1, and a controller 8 is fixedly connected to the top right side of the front of the main body 1.

[0036]Wherein, feeding devi...

Embodiment 2

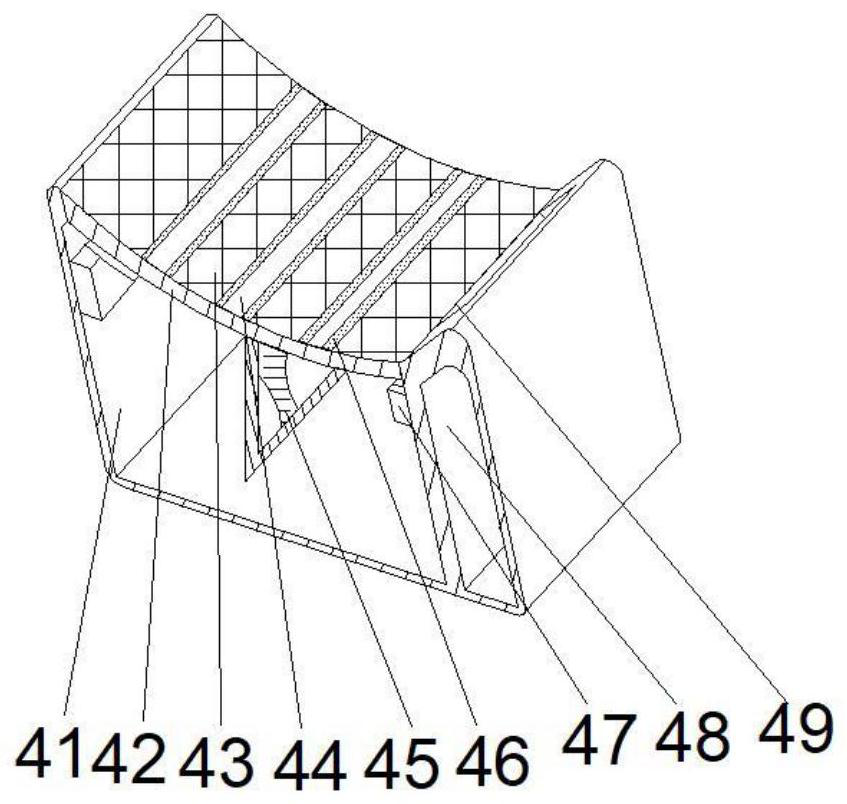

[0039] Such as Figure 1-3 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the collection device 4 includes a box body 41, the top of the box body 41 is provided with an arc-shaped top plate 42, and the top of the arc-shaped top plate 42 is provided with a circulation surface 43 , the arc top plate 42 is fixedly connected with a baffle 44, the two sides of the baffle 44 are fixedly connected with a magnet 46, the top of the inner wall on both sides of the box body 41 is fixedly connected with a connecting block 47, and the middle position of the inner cavity bottom of the box body 41 is fixed A partition 45 is connected, a waste bin 48 is arranged on the right side of the box body 41 , and a collection port 49 is opened on the top of the waste bin 48 .

[0040] When in use, clamp the workpiece, press the open key on the controller 8, input the program, close the protective door, the moving mechanism 7 works, the moving mechanism 7 d...

Embodiment 3

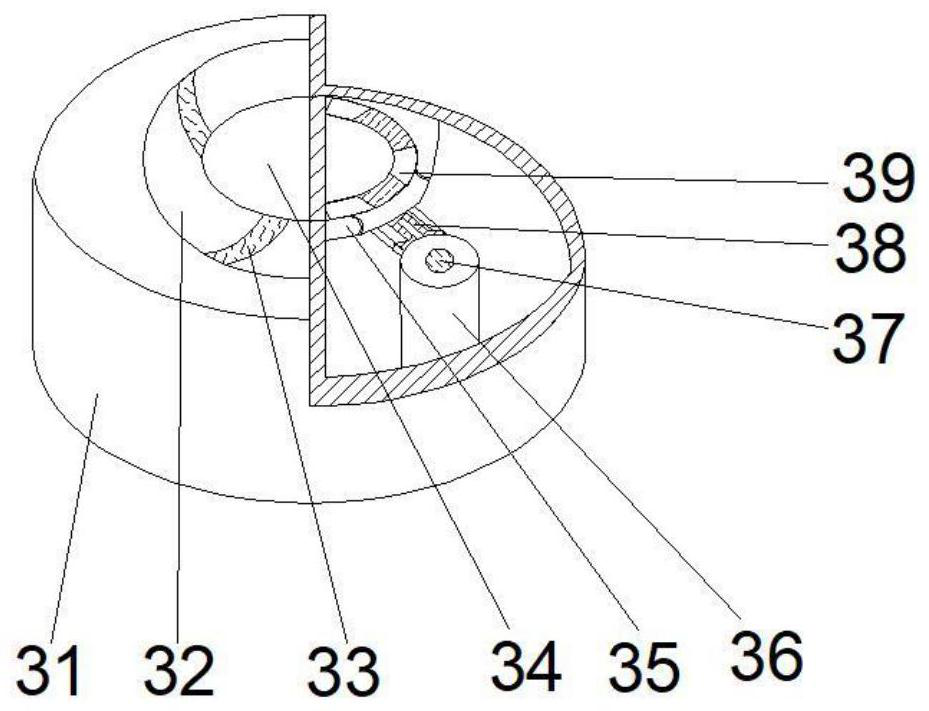

[0042] Such as Figure 1-6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the bottom of the arc-shaped block 33 is fixedly connected with an elastic ball 334, and the top of the arc-shaped block 334 is fixedly connected with a connecting plate 331. A swing plate 332 is provided at the bottom of the plate 331 , and a booster plate 333 is fixedly connected to the right side of the bottom of the swing plate 332 .

[0043] Wherein, the top of the arc-shaped baffle is provided with a circulation groove 421, and the bottom of the inner cavity of the circulation groove 421 is fixedly connected with an adjusting plate 422, and the top right side of the arc-shaped top plate 42 is provided with a groove 425, and the bottom right side of the arc-shaped top plate 42 A top post 424 is fixedly connected, and the right side of the arc-shaped top plate 42 is located on both sides of the top post 424 to open through holes 423 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com