Iron metal pipe positioning and cutting device and working method thereof

A technology for positioning cutting and metal pipes, which is applied in the direction of shearing devices, metal processing equipment, and attachments of shearing machines, etc. It can solve problems such as deviations in artificial drawing lines, cutting deviations, and easy accidental injuries to staff, etc., to achieve convenient removal and Storage, convenient and stable adjustment, increase the effect of clamping stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

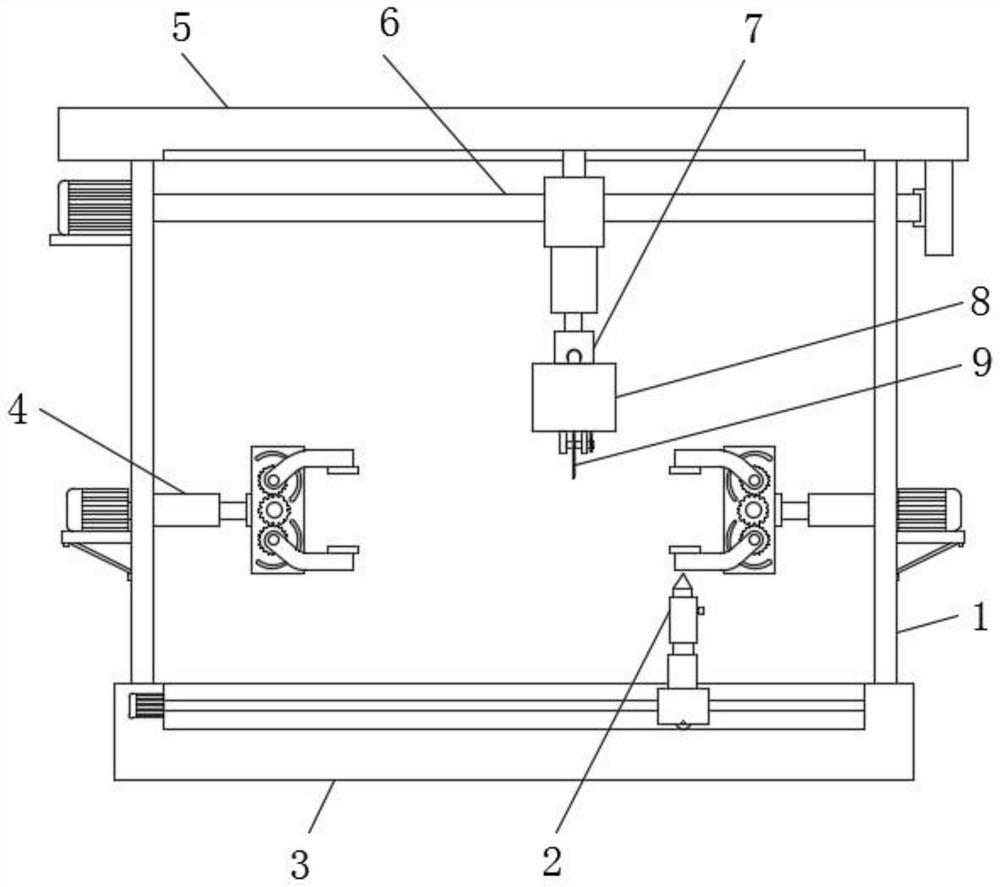

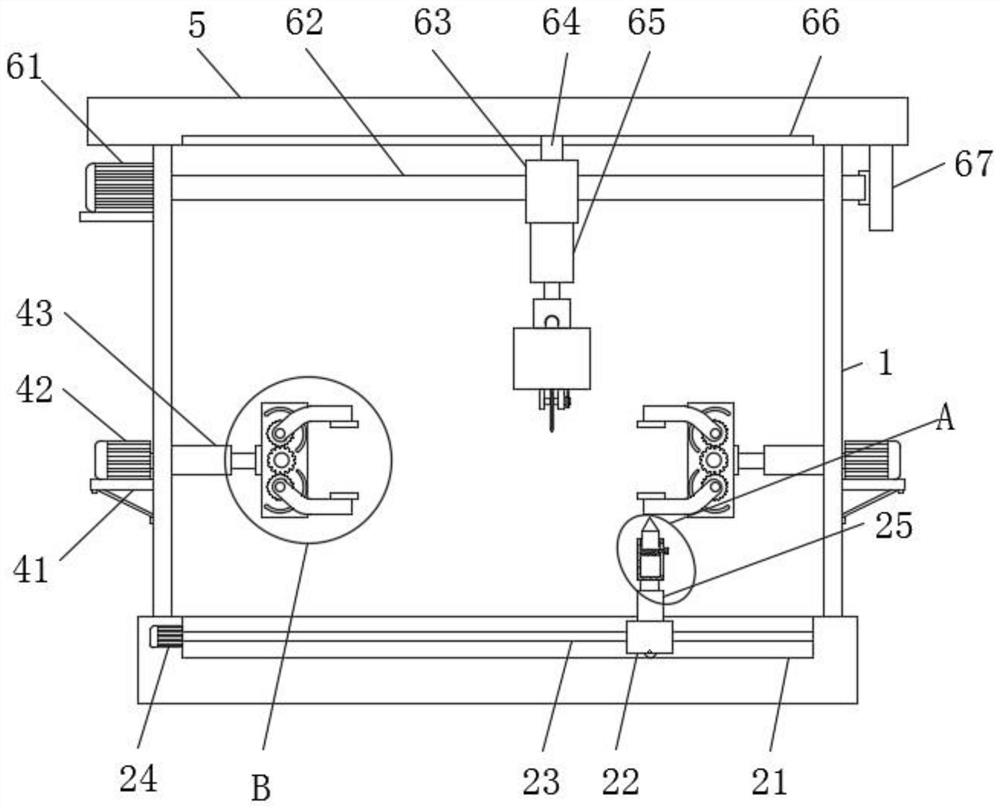

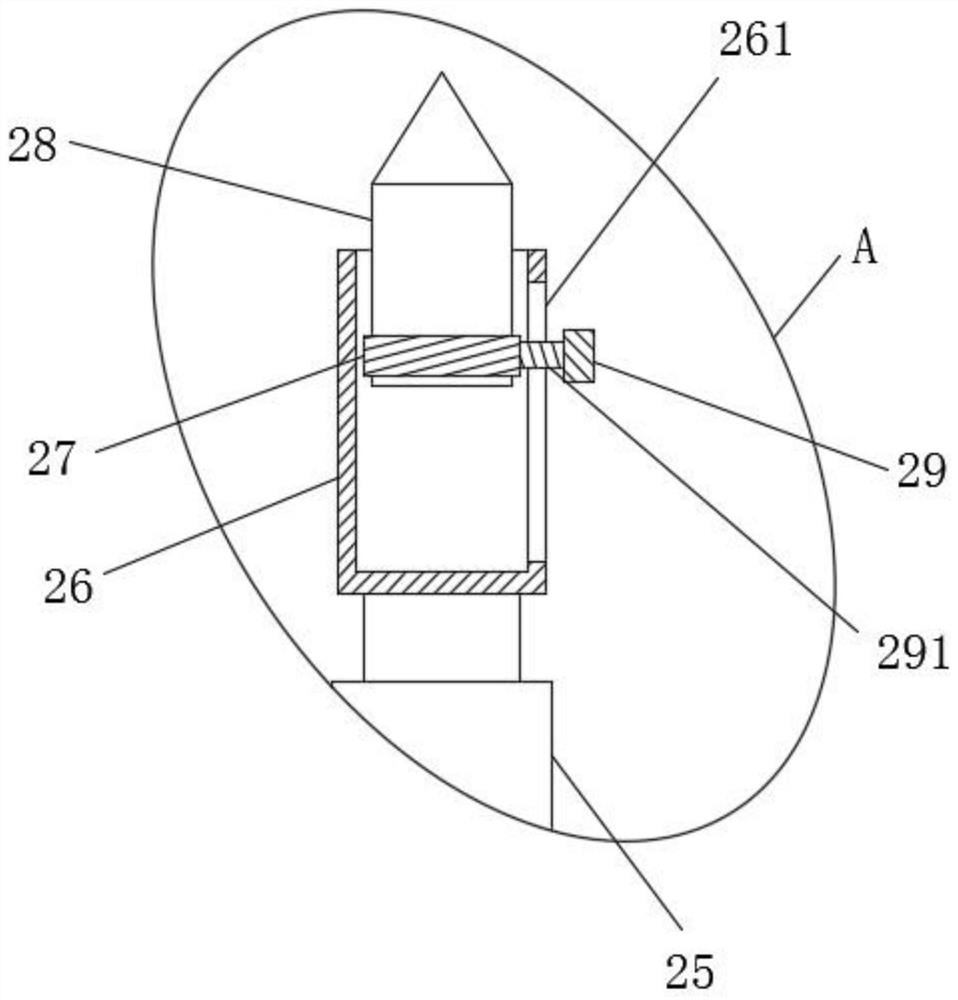

[0035] see Figure 1-6 As shown, a ferrous metal pipe positioning and cutting device includes a fixed rod 1, a positioning component 2, a bottom plate 3, a clamping component 4, a top plate 5, an adjustment component 6, a dust suction component 7, a cutting machine body 8 and a cutting piece 9 , the upper side of the bottom plate 3 is provided with a positioning assembly 2, the upper end of the bottom plate 3 is installed with four sets of fixed rods 1, the upper end of the four sets of fixed rods 1 is installed with a top plate 5, the lower end of the top plate 5 is provided with an adjustment assembly 6, and the upper side of the bottom plate 3 is provided with a clamping Component 4, the lower side of the top plate 5 is equipped with a cutting machine body 8, the lower side of the cutting machine body 8 is equipped with a cutting blade 9, and the inside of the cutting machine body 8 is provided with a dust suction component 7;

[0036] The positioning assembly 2 includes an...

Embodiment 2

[0046] A working method for positioning and cutting an iron metal pipe. The working method for positioning and cutting an iron metal pipe includes the following specific steps:

[0047] Step 1, when the iron metal pipe is positioned and cut, the second electric telescopic rod 43 is energized to drive the installation plate 44 and the clamp 45 to adjust to the appropriate distance, and then the staff places the two sections of the metal tube in the clamp 45 respectively, and fixes the plate The clamping motor 491 on the 492 is energized and works, and the clamping motor 491 drives the driving rod 49 to run, and the first driving gear 48 and the second driving gear 481 drive the driven gear 47 respectively, because the driven gear 47 is installed on the transmission rod 46 , the transmission rod 46 will also rotate, and the transmission rod 46 will drive the clamp 45 again. Because the tooth inclination angles of the first driving gear 48 and the second driving gear 481 are oppos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com