Automatic rewinding system for PVC decorative film

A decorative film and rewinding roller technology, which is applied in the directions of winding strips, transportation and packaging, and sending objects, can solve the problems of increasing equipment costs and equipment footprints, not being able to adapt to the needs of the industry, and requiring a lot of manpower. , to achieve the effect of ensuring portability and safety, reducing labor input and meeting production requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

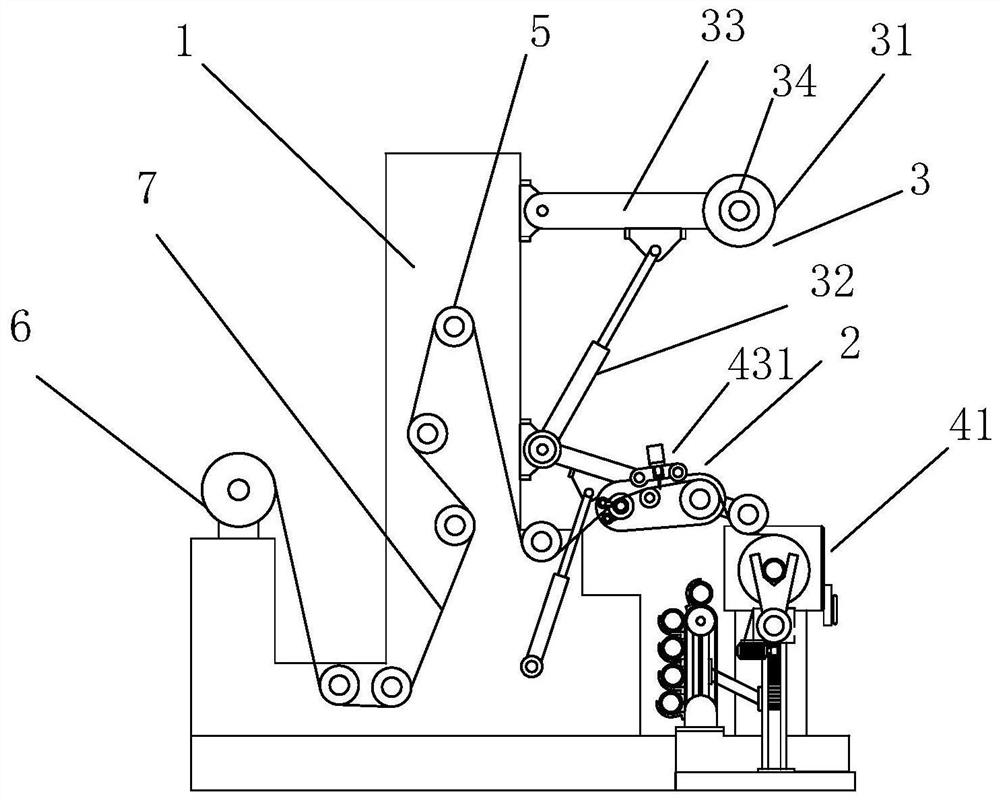

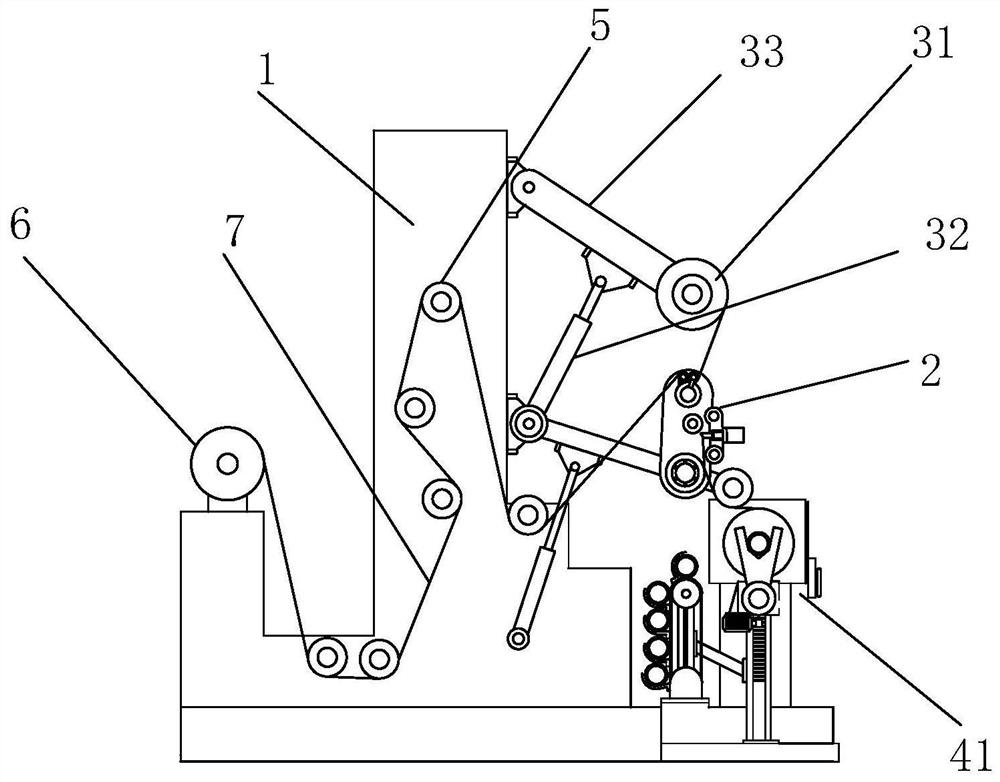

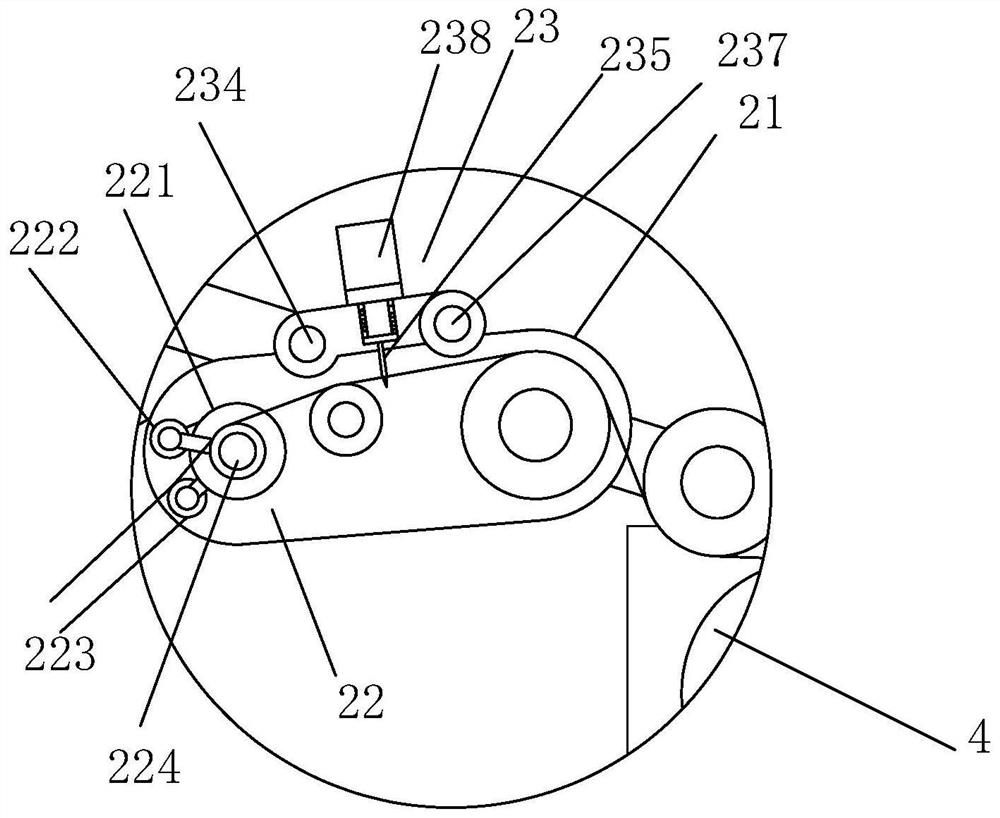

[0028] see Figure 1-Figure 8 , the present embodiment is an automatic PVC decorative film rewinding system, including an equipment body 1, a material distributing mechanism 2, a waste material rewinding mechanism 3, and a finished product rewinding mechanism 4. The equipment body 1 is provided with several The guide roller 5 for the threading of the coil material belt 7, the head end of the equipment body is provided with the raw material roller 6 to be rewound the raw material belt 7, and the rewinding material belt 7 is arranged by the original material roller through the equipment body 1 successively. The guide roller 5 and the distributing mechanism 2 are connected with the finished product rewinding mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com