Unpowered automatic opening and closing feeding hopper for medical waste incineration

An automatic opening and closing, medical waste technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of reducing the safety of medical waste treatment, medical waste crushing, increasing equipment costs, etc., to improve people's health and medical care level, prevention of disease transmission, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

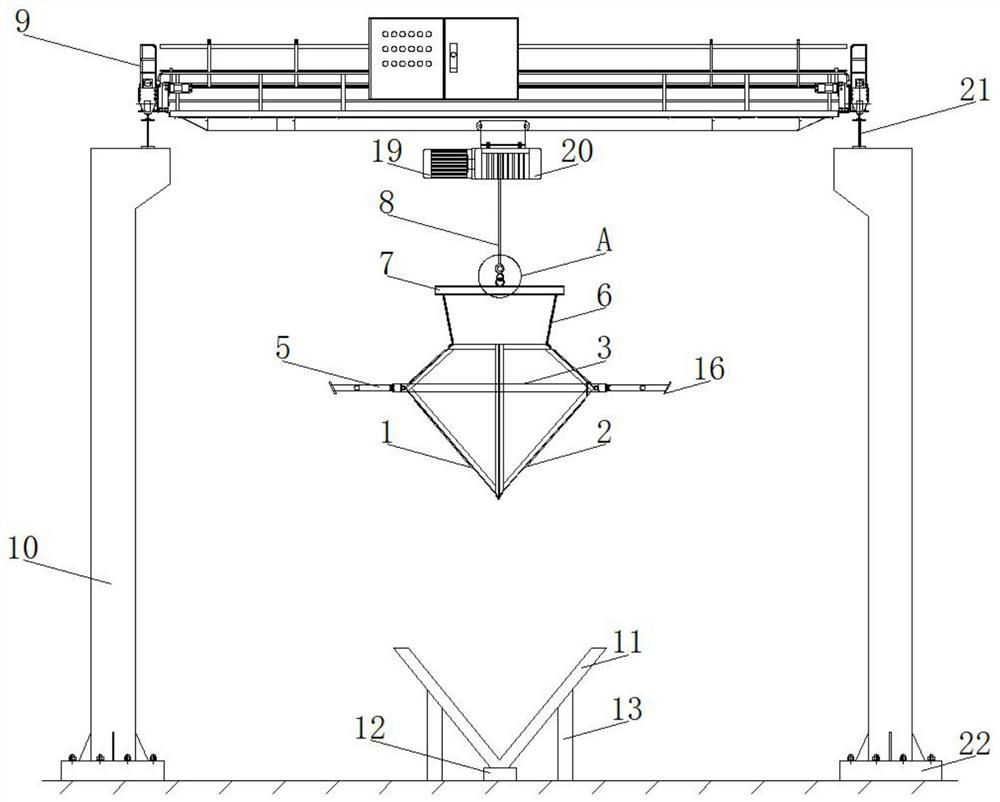

[0021] according to figure 1 , 2 , 4, and 5, this embodiment provides a non-powered automatic opening and closing hopper for medical waste incineration, including a non-powered feeding bucket, and the non-powered loading bucket includes a relatively arranged first loading bucket. Bucket 1 and the second loading bucket 2, the second loading bucket 2 is smaller than the first loading bucket 1 and is located inside the first loading bucket 1, the first loading bucket 1 and The outer side of the second loading bucket 2 is provided with a frame body 3, and the outsides of the first loading bucket 1 and the second loading bucket 2 are hinged on the frame body 3 by hinges 4, and the frame body 3 Support frames 5 are provided on both sides, and both sides of the top of the first loading bucket 1 and the second loading bucket 2 are connected to the bottom end of the hanger 7 through the hanging chain 6, and the top of the hanger 7 is connected to the bottom end of the hanger 7 by the ...

Embodiment 2

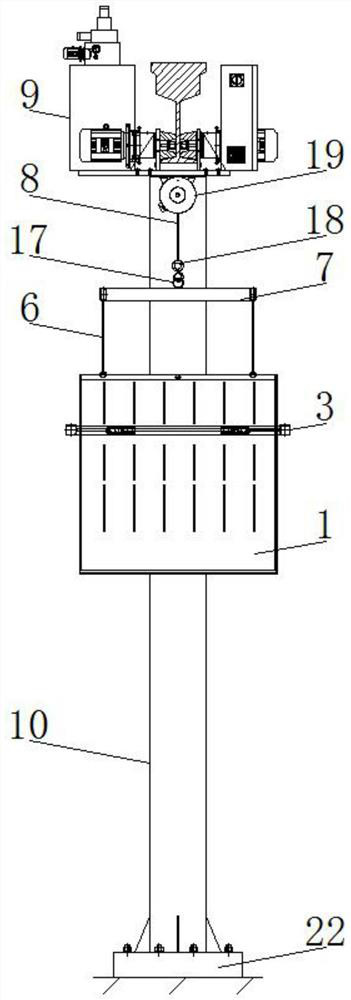

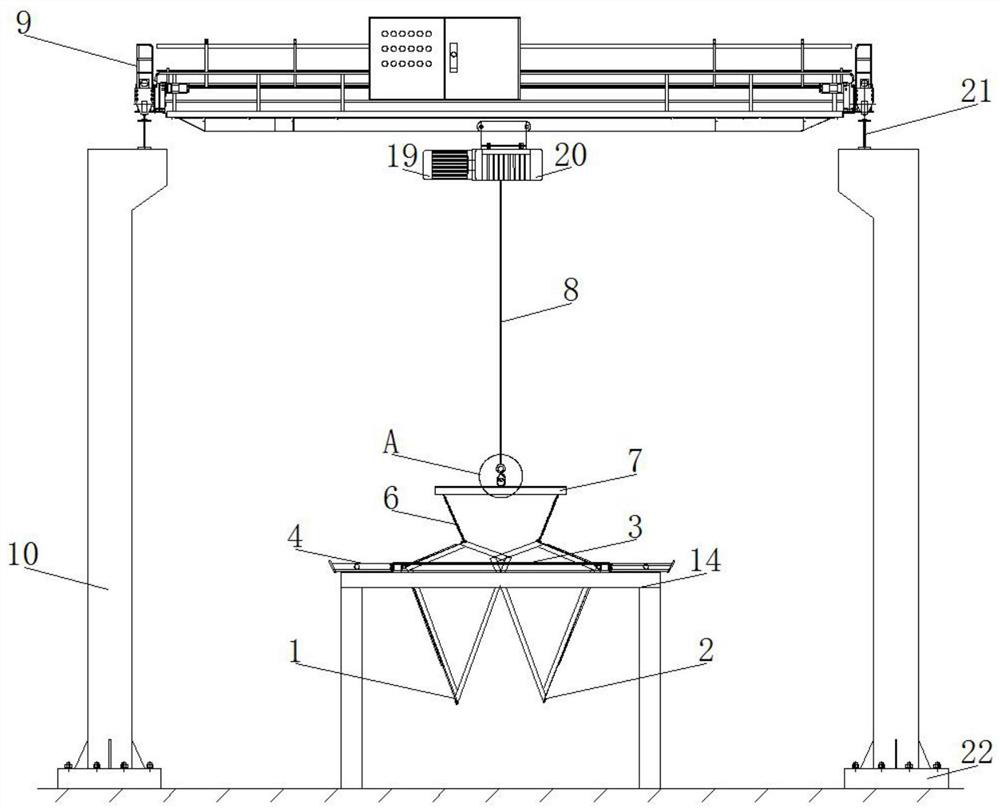

[0028] according to figure 2 , 3 , 4, and 5, this embodiment provides a non-powered automatic opening and closing hopper for medical waste incineration, including a non-powered feeding bucket, and the non-powered loading bucket includes a relatively arranged first loading bucket. Bucket 1 and the second loading bucket 2, the second loading bucket 2 is smaller than the first loading bucket 1 and is located inside the first loading bucket 1, the first loading bucket 1 and The outer side of the second loading bucket 2 is provided with a frame body 3, and the outsides of the first loading bucket 1 and the second loading bucket 2 are hinged on the frame body 3 by hinges 4, and the frame body 3 Support frames 5 are provided on both sides, and both sides of the top of the first loading bucket 1 and the second loading bucket 2 are connected to the bottom end of the hanger 7 through the hanging chain 6, and the top of the hanger 7 is connected to the bottom end of the hanger 7 by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com