Novel electric power-assisted lifting mechanism

A technology of electric power assist and lifting mechanism, applied in the direction of lifting device, etc., can solve the problems of large occupied space, inconvenient maintenance, environmental impact, etc., and achieve the effect of saving occupied space and avoiding oil leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

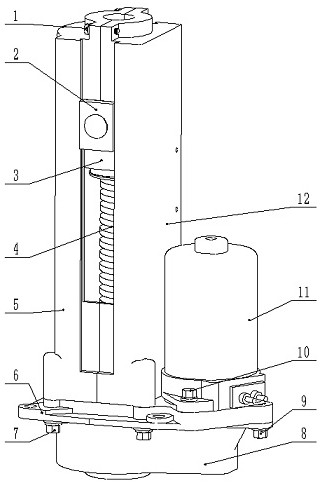

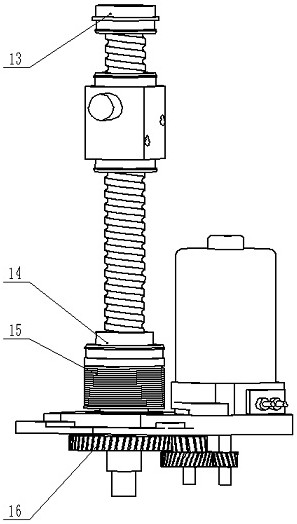

[0011] As shown in the figure, a new electric power-assisted lifting mechanism is characterized in that: a new spring stop mechanism, including an upper fastening bolt, a moving block, a nut, a screw, a left shell, a base, a lower fastening bolt, Gear box, motor fastening bolts, motor, right shell, sliding bearing, shock absorber, spring stop mechanism, gear set, etc. Following the principle of simple structure, convenient installation, timely stop, stable and reliable work and environmental protection, the motor 11 is assembled with the base 6 through the motor fastening bolt 10, and after the gear set 16 is assembled in the gear box 8, the gear The box 8 is connected with the base 6 through the fastening bolt 9 of the shell, the nut 3 is assembled on the screw rod 4, the sliding bearing 13, the shock absorbing sleeve 14 and the spring stop mechanism 15 are penetrated on the screw rod 4, and the screw rod 4 is penetrated into the On the base 6, assemble the moving block 2 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com