Process and system for continuously producing m-aminoacetanilide hydrochloride at high temperature under pressure

A technology of aminoacetanilide hydrochloride, high temperature and pressure, applied in the preparation of carboxylic acid amides, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of long production cycle, large equipment occupation area, large heat loss and the like , to achieve high production efficiency and benefits, improve production efficiency, and reduce equipment effects

Active Publication Date: 2021-02-12

ZHEJIANG DIBANG CHEM +1

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, it adopts a batch production process, which requires a large reactor volume, poor mass and heat transfer effects, and large heat loss, which is not conducive to energy saving and emission reduction.

In addition, intermittent production also has problems such as long production cycle and product quality batch differences.

[0005] Patent CN108147975A introduces a process for continuous production of m-aminoacetanilide hydrochloride, which realizes the continuous feeding and discharging of reaction materials. Since the whole production process is under normal pressure conditions, the mother liquor water absorbs hydrogen chloride and increases the concentration. Special absorption towers and other devices, and the increase of the reaction temperature is limited (up to 110°C), which affects the reaction rate, so there are pro

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

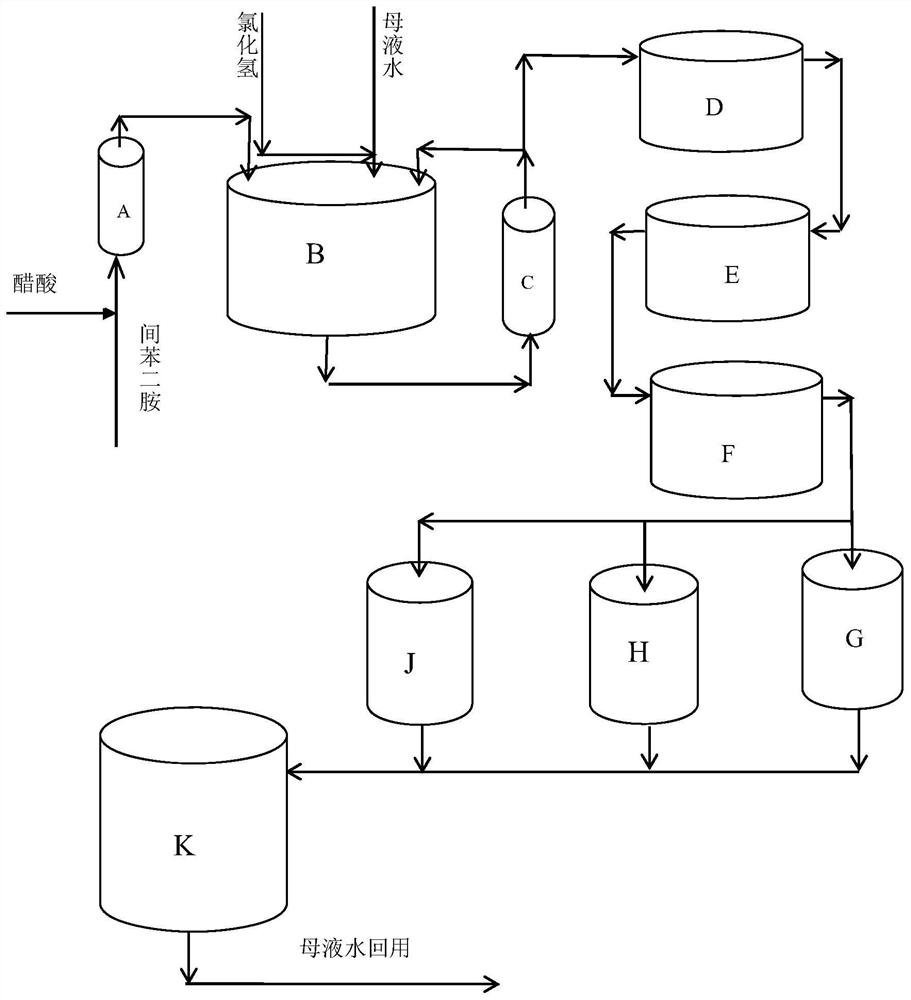

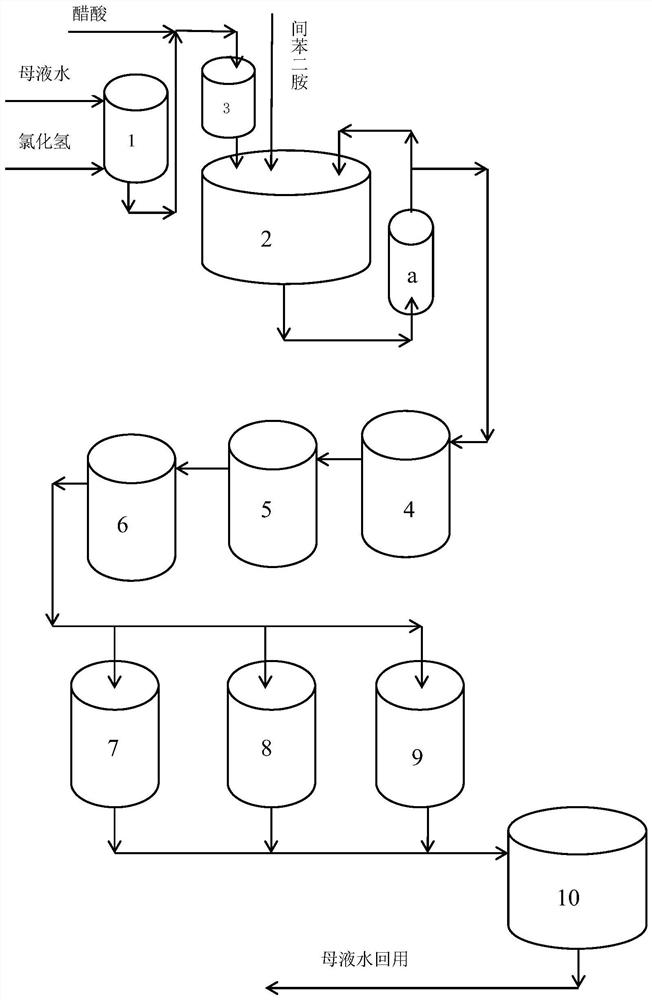

The invention discloses a process and a system for continuously producing m-aminoacetanilide hydrochloride at high temperature under pressure. The process comprises the following steps: continuously conveying mother liquor water, acetic acid, m-phenylenediamine and hydrogen chloride gas to a closed supergravity reactor, continuously discharging materials in the supergravity reactor, part of the materials passing through a closed first heat exchanger and then returning to the supergravity reactor for circulation, and part of the materials entering a crystallization kettle and then being treatedby a separation device; obtaining an m-aminoacetanilide hydrochloride finished product and mother liquor water, and collecting and recycling the mother liquor water. The system comprises a second heat exchanger, a closed supergravity reactor, a closed first heat exchanger, a crystallization kettle, a separation device and a mother liquor water collection device which are connected in sequence. The second heat exchanger is used for preheating acetic acid and m-phenylenediamine; and a closed loop is formed between the supergravity reactor and the first heat exchanger.

Description

technical field [0001] The invention relates to the technical field of production of dye intermediates, in particular to a process and system for continuous production of m-aminoacetanilide hydrochloride under high temperature and pressure. Background technique [0002] M-aminoacetanilide is a widely used chemical raw material, widely used in disperse dyes, reactive dyes and pharmaceutical intermediates, mainly used to prepare reactive yellow K-RN and disperse dye intermediates, and is in great demand. [0003] The synthesis of m-aminoacetanilide hydrochloride, the traditional production method uses m-phenylenediamine, acetic acid, hydrochloric acid solution and the previous cycle of mother liquor water after concentration, and the temperature is raised to 90°C for reaction. After the reaction is completed, cooling crystallization and suction filtration Or centrifuge to get the product. The separated mother liquor water is distilled under reduced pressure, concentrated and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C231/02C07C231/12C07C231/24C07C233/43B01D53/14

CPCB01D53/1456B01D2257/2045B01D2257/70B01J3/002B01J3/04C07C231/02C07C231/12C07C231/24C07C233/43

Inventor 陈晓栋孙宝昌刘泊良唐智勇罗勇陈建峰徐万福邹海魁初广文张亮亮徐斌

Owner ZHEJIANG DIBANG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com