Steel for high-toughness rotary blade, and heat treatment method thereof

A heat treatment method and the technology of the rotary tiller, which are applied in the field of metallurgy, can solve problems such as high production cost, high alloy cost, and complicated process, and achieve the effects of low production cost, improved hardenability, and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

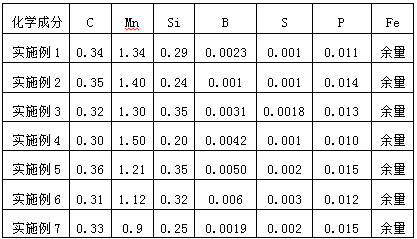

[0027] See Table 1 for the chemical composition and mass percentage of the steel for the high-toughness rotary tillage blade in this example.

[0028] The heat treatment method of the high-toughness rotary tiller steel in this embodiment includes the following steps in sequence: quenching, heat preservation, water cooling, tempering and heat preservation. Fire, keep warm for 15min.

[0029] The test results of the mechanical properties of the high-toughness rotary tiller steel in this example are: the hardness is 46HRC and the impact value is 20J.

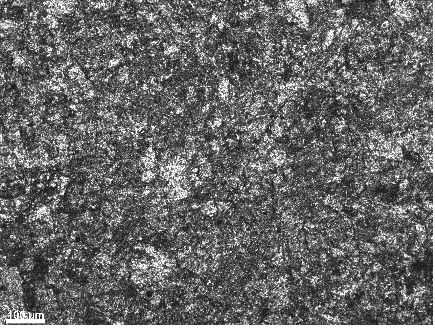

[0030] The metallographic structure of the high-toughness rotary tiller blade steel in this embodiment is shown in figure 1 .

Embodiment 2

[0032] See Table 1 for the chemical composition and mass percentage of the steel for the high-toughness rotary tillage blade in this example.

[0033] The heat treatment method of the high-toughness rotary tiller steel in this embodiment includes the following steps in sequence: quenching, heat preservation, water cooling, tempering and heat preservation. The specific process parameters are: quenching temperature is 880°C, heat preservation for 10min, water cooling at room temperature, and tempering at 320°C , keep warm for 21 minutes.

[0034] The test results of the mechanical properties of the high-toughness rotary tiller blade steel in this example are: the hardness is 47 HRC and the impact value is 18 J.

Embodiment 3

[0036] See Table 1 for the chemical composition and mass percentage of the steel for the high-toughness rotary tillage blade in this example.

[0037] The heat treatment method of the high-toughness rotary tiller steel in this embodiment includes the following steps in sequence: quenching, heat preservation, water cooling, tempering and heat preservation. Fire, keep warm for 22min.

[0038] The test results of the mechanical properties of the high-toughness rotary tiller steel in this example are: the hardness is 45HRC and the impact value is 22J.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shock value | aaaaa | aaaaa |

| Shock value | aaaaa | aaaaa |

| Shock value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com