Device for evaluating corrosion resistance of petroleum pipe in oil-water coupling medium

A technology of coupling medium and corrosion resistance, which is applied in the field of test devices for evaluating the corrosion resistance of petroleum pipes in oil-water coupling medium, and can solve the problem of inability to evaluate the corrosion resistance of anti-corrosion coatings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

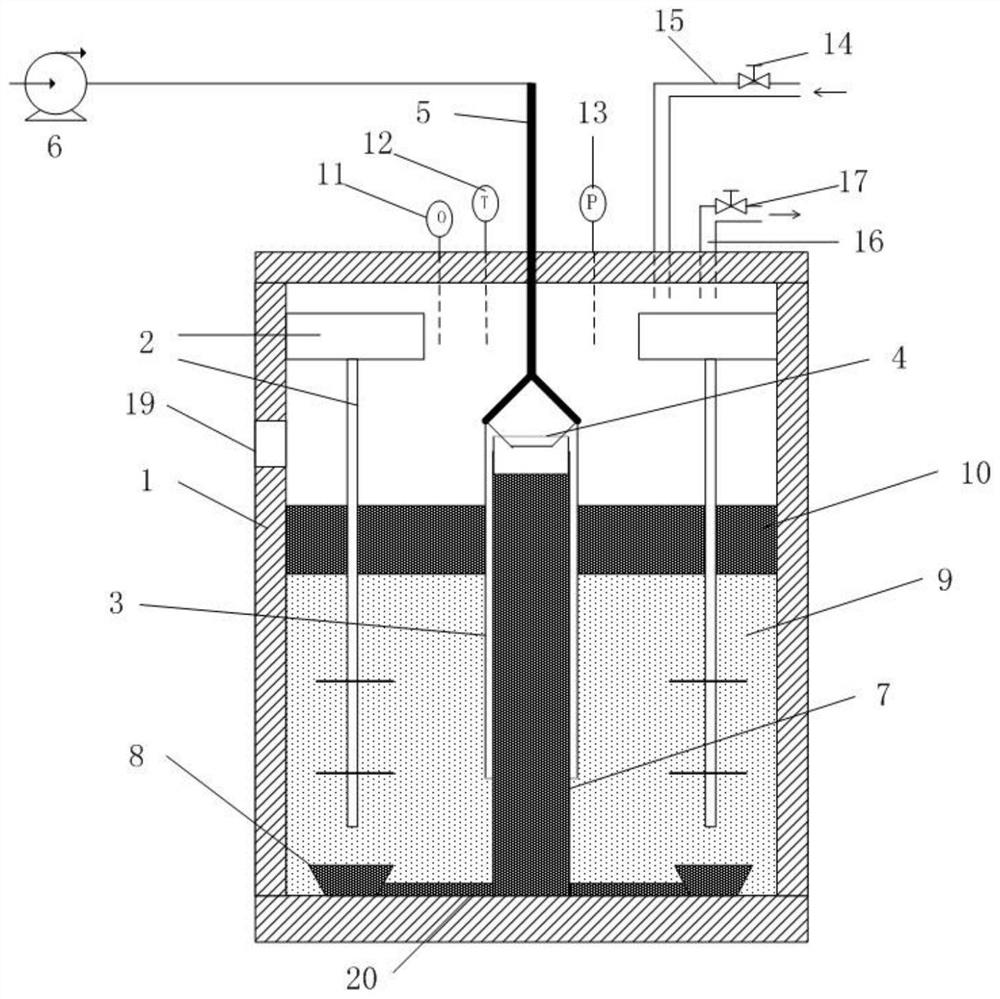

[0032] like figure 1 As shown, the test device for evaluating the corrosion resistance of oil pipes in the oil-water coupling medium of the present invention mainly includes a high temperature and high pressure system, a crude oil circulation system and a monitoring system.

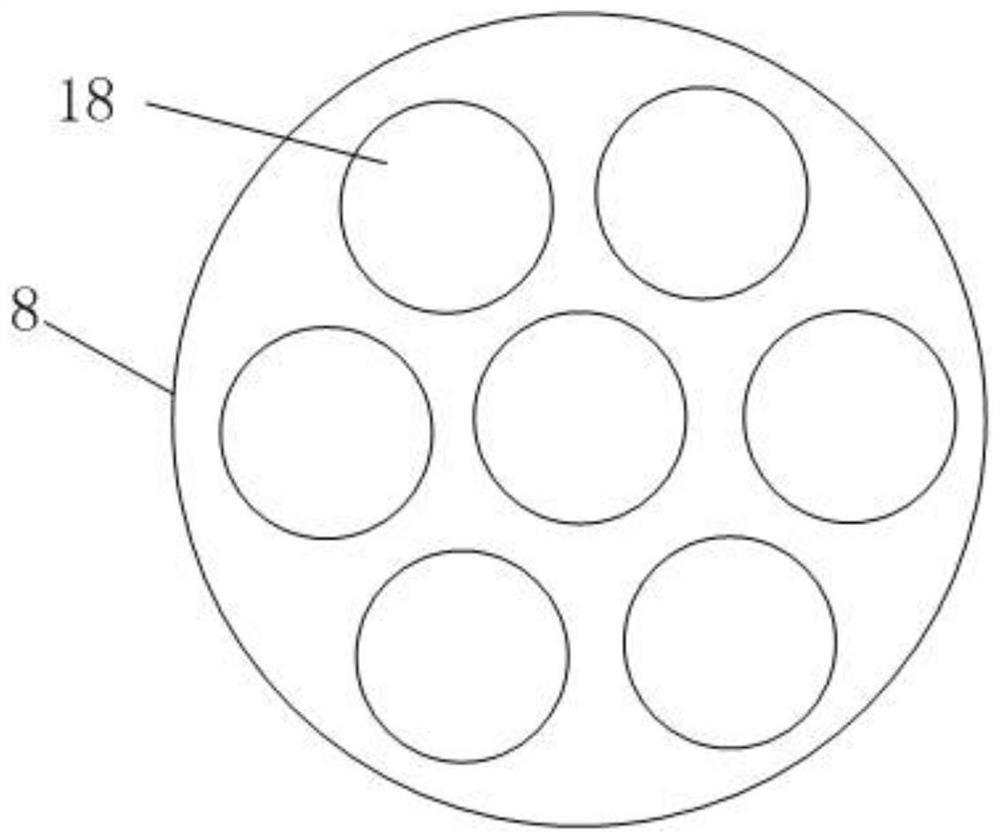

[0033] like figure 1 As shown, the high-temperature and high-pressure system includes: a high-temperature autoclave 1, a sample installation device 2 is arranged in the high-temperature autoclave 1, an air inlet pipe 15 is connected to the high-temperature autoclave 1, and an air inlet valve 14 is arranged on the air inlet pipe 15. 1 is connected with an air outlet pipe 16, an air outlet valve 17 is arranged on the air outlet pipe 16, and a transparent observation window 19 is arranged on the high temperature and autocl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com