Multi-level inventory quota formulating method based on data driving

A data-driven, quota-based technology, applied in other database retrieval, other database query, data processing applications, etc., can solve problems such as shortage, inventory collaborative optimization, and high inventory level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

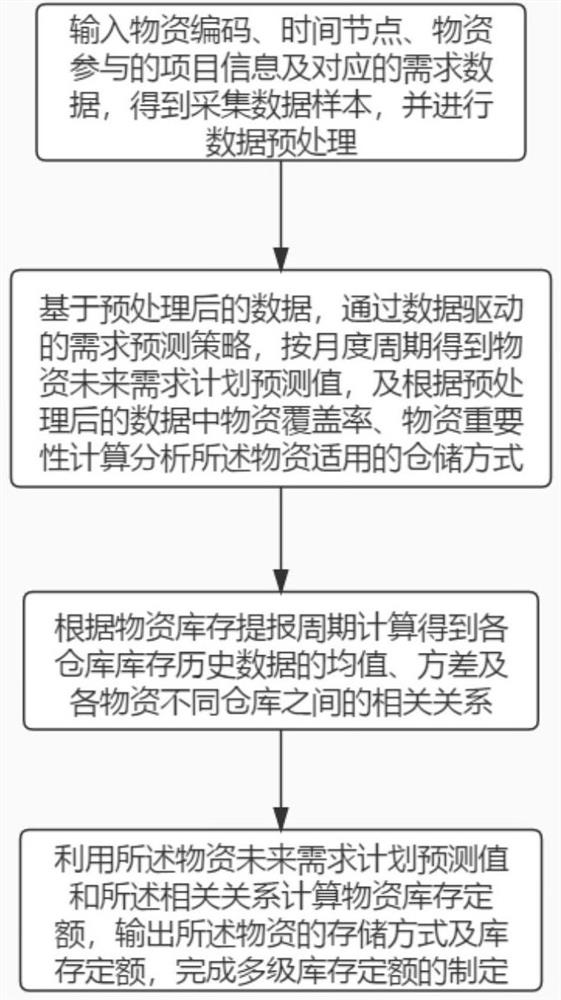

[0037] refer to figure 1 , which is an embodiment of the present invention, provides a data-driven multi-level inventory quota formulation method, including:

[0038] S1: Input material code, time node, project information of material participation and corresponding demand data, obtain collected data samples, and perform data preprocessing; it should be noted that,

[0039] Data preprocessing includes:

[0040] Complete the missing values in the data according to the mean, mode, and 0 strategies;

[0041] Split the material description data to obtain the type index of the material;

[0042] Convert data formats as required, including text, numeric and date;

[0043] Remove duplicate data and delete unnecessary indicators.

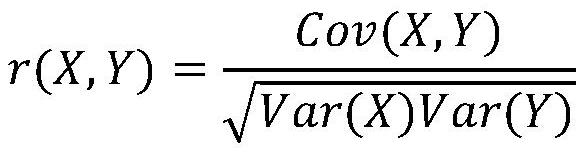

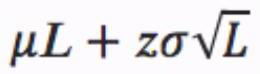

[0044] S2: Based on the preprocessed data, through the data-driven demand forecast strategy, the forecast value of the future demand plan of materials is obtained on a monthly basis, and the materials are calculated and analyzed according to the materia...

Embodiment 2

[0071] In order to verify and explain the technical effect adopted in this method, this embodiment adopts the traditional technical scheme and the method of the present invention to conduct a comparative test, and compares the test results by means of scientific demonstration to verify the real effect of this method.

[0072] The traditional determination of the inventory plan does not consider the correlation between the warehouses, and they are combined for storage. In addition, different materials may need to meet different service levels according to their characteristics. The inventory quota determined by the traditional method may have too much inventory, resulting in excessive funds. Occupation, high management costs and other issues.

[0073] In this embodiment, traditional single-warehouse storage and this method will be used to measure and compare the inventory quotas of warehouses in real time. The inventory consumption of each warehouse by cycle for a product is sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com