Fabric defect detection method in warp knitting process

A detection method and defect technology, applied in manufacturing computing systems, image analysis, image enhancement, etc., can solve problems such as resource waste and poor efficiency, and achieve the effects of improving applicability, stability, and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described below in conjunction with accompanying drawing;

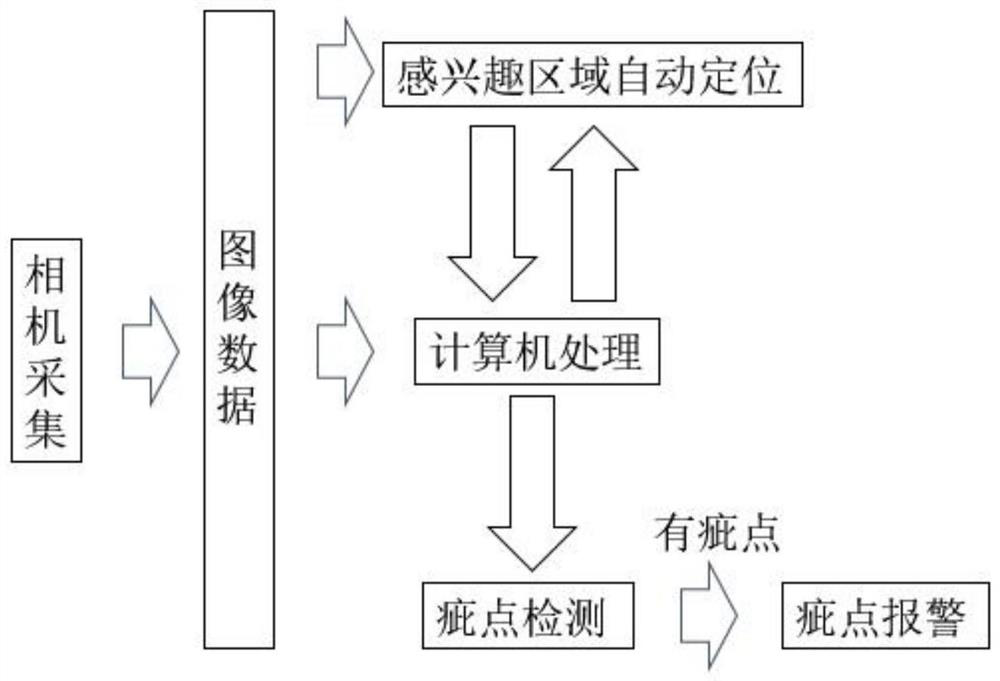

[0028] The invention designs a fast detection algorithm for fabric defects in the warp knitting process, figure 1 It is the processing flowchart of the algorithm of the present invention, which is divided into two parts: the automatic calculation of the region of interest and the detection of fabric defects; for each picture collected, the computer automatically calculates the region of interest of the picture first, that is, the weaving of the warp knitting machine area, and then cut the size of the region of interest from the collected pictures, perform defect detection on the cropped pictures, and alarm or shut down after detecting the defects.

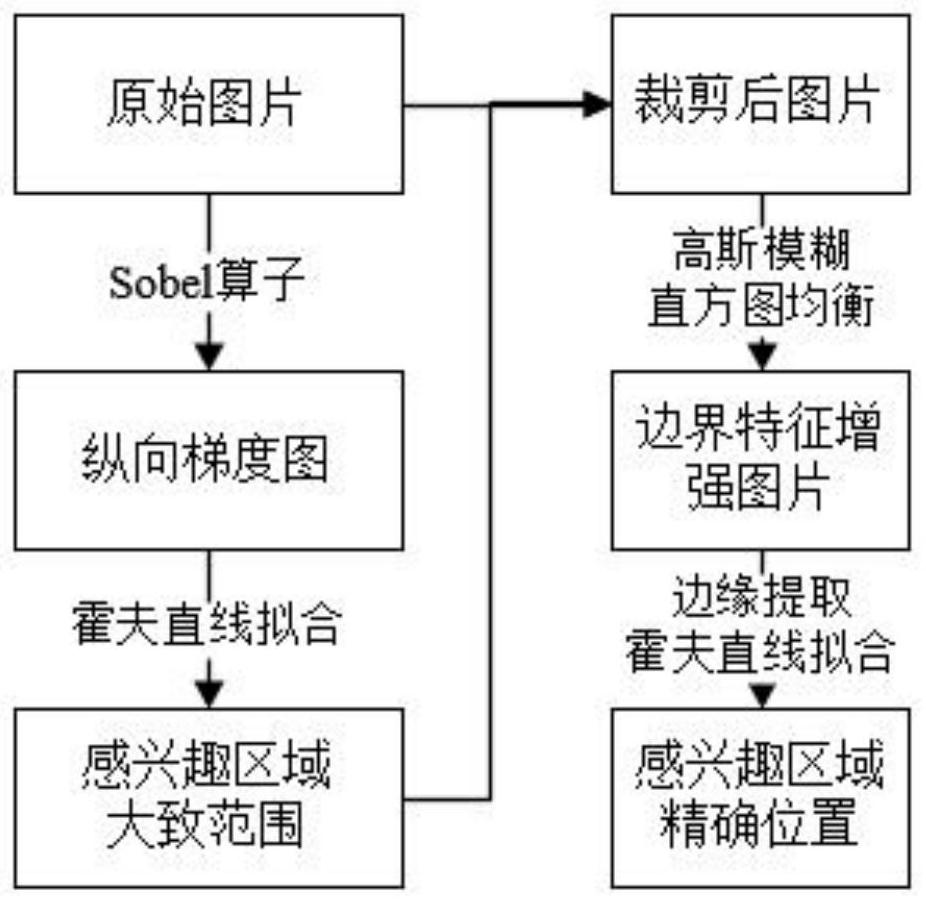

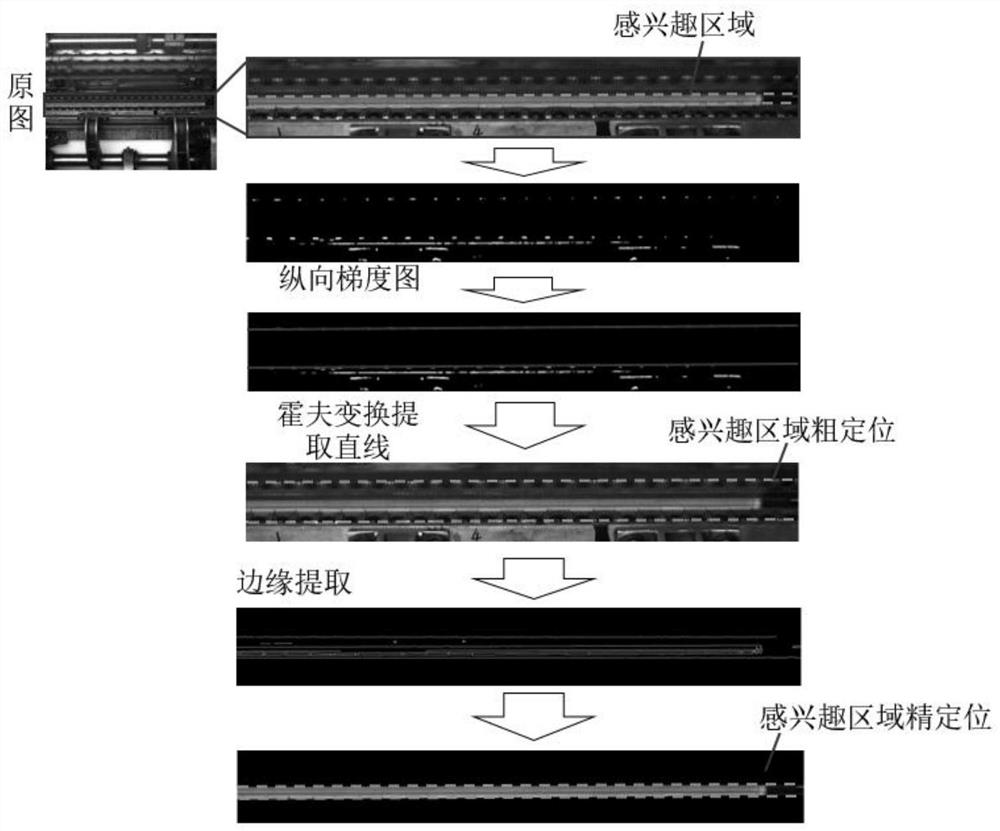

[0029] The processing flowchart of the region of interest automatic positioning algorithm mentioned in the present invention is as figure 2 As shown; the automatic positioning algorithm of the region of interest is divided into two parts: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com