Microneedle type wire connecting device

A technology of wire connection and microneedle, which is applied in the direction of conductive connection, connection, connection insulation, etc., can solve problems such as insecurity, burning failure, and oxidation of the connection, and achieve high mechanical strength and hardness, prevent distortion and deformation, and reduce production costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

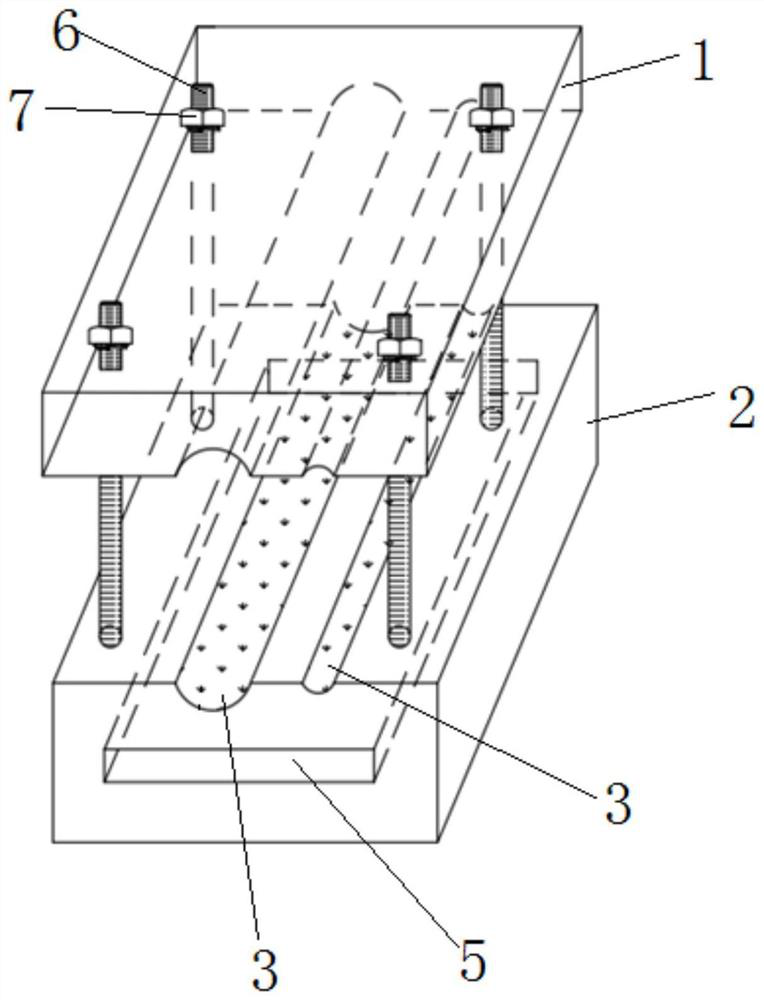

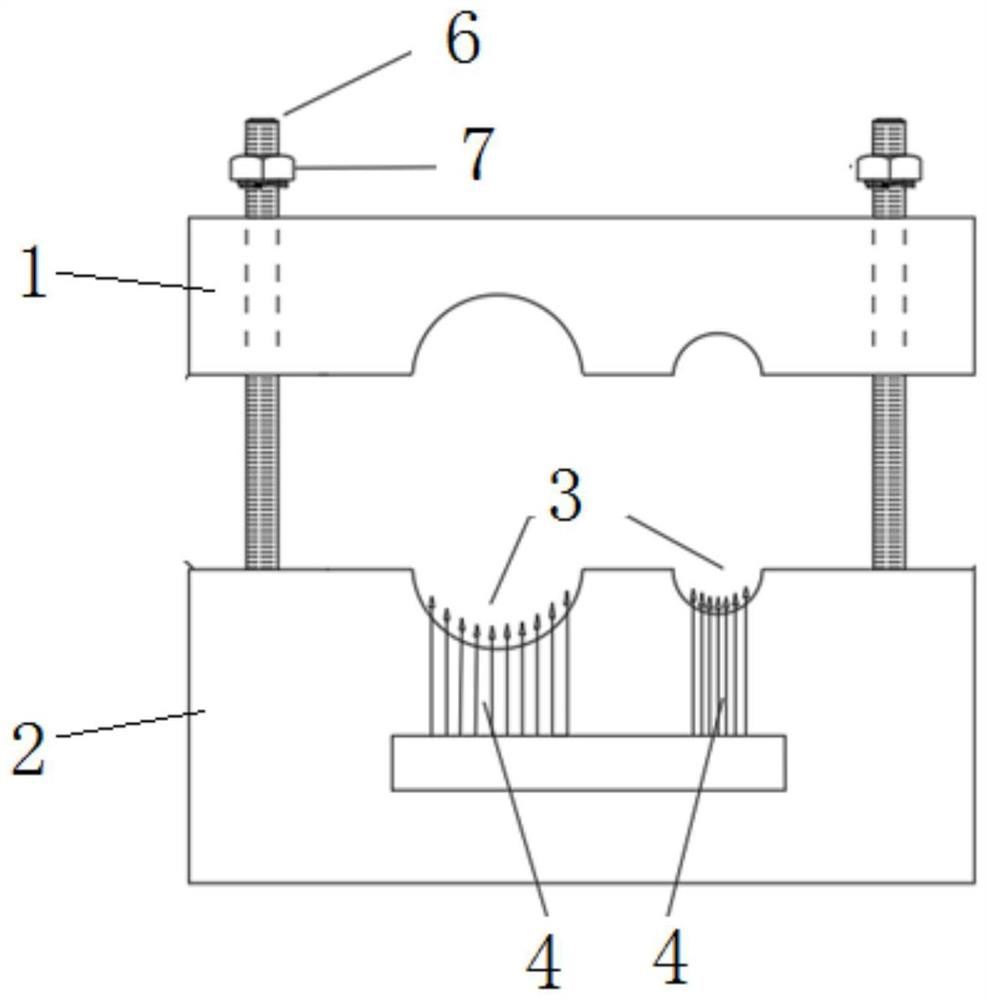

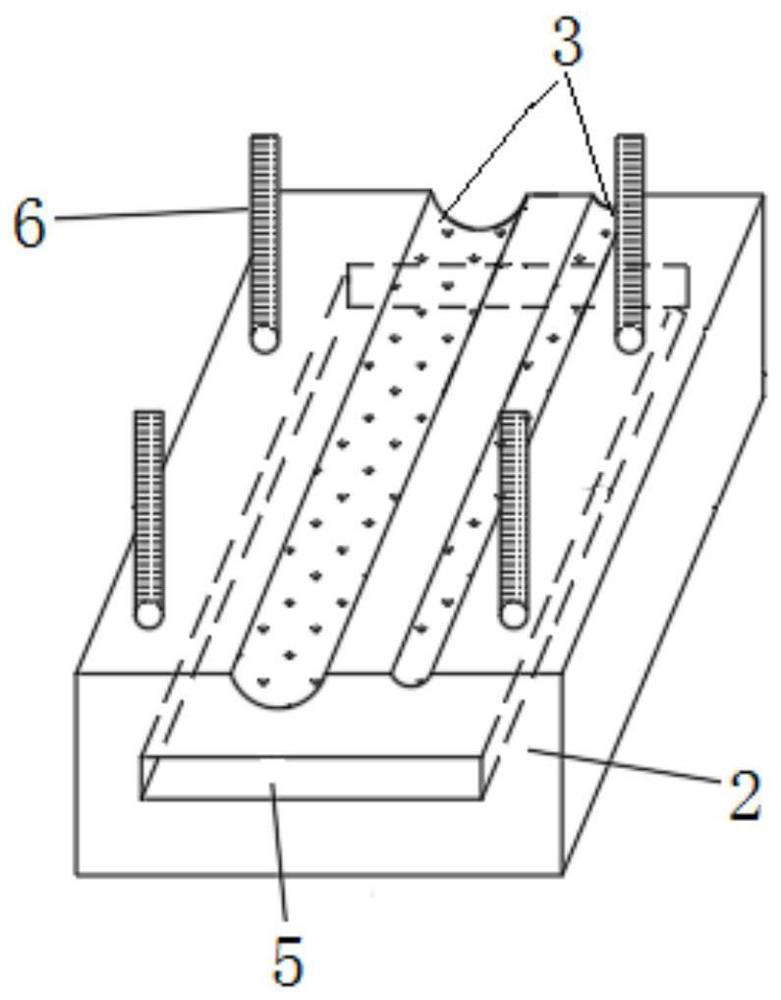

[0034] Such as Figure 1~3 The microneedle wire connection device shown includes an upper casing 1 , a lower casing 2 , four bolts 6 and matching nuts 7 , a conductor 5 and several conductive alloy microneedles 4 . Both the upper casing 1 and the lower casing 2 adopt a rectangular structure made of insulating engineering plastics, and the two are connected by four bolts 6 evenly distributed at the four corners. The wire groove 3 on the lower casing 2 is a half groove body structure, which is arranged opposite to the half groove body provided on the upper casing 1, and the two half groove bodies can be combined into a whole groove body adapted to the wire. The conductor 5 built in the lower case 2 is a plate-like structure, and its length direction is consistent with the axis direction of the wire groove 3 .

[0035] When the electric wire and cable need to be connected, the main wire and the guidance wire are respectively inserted in the two wire grooves 3 . Rotate the nut 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com