Balloon catheter manufacturing method and device using thermosetting resin

A technology for a balloon catheter and a manufacturing method, which is applied to balloon catheters, catheters, applications, etc., can solve the problems of intermittent operation procedures, complicated manufacturing procedures, and unspecified drying procedures, and achieves fast production and saves manufacturing time and costs. , the effect of preventing adverse phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

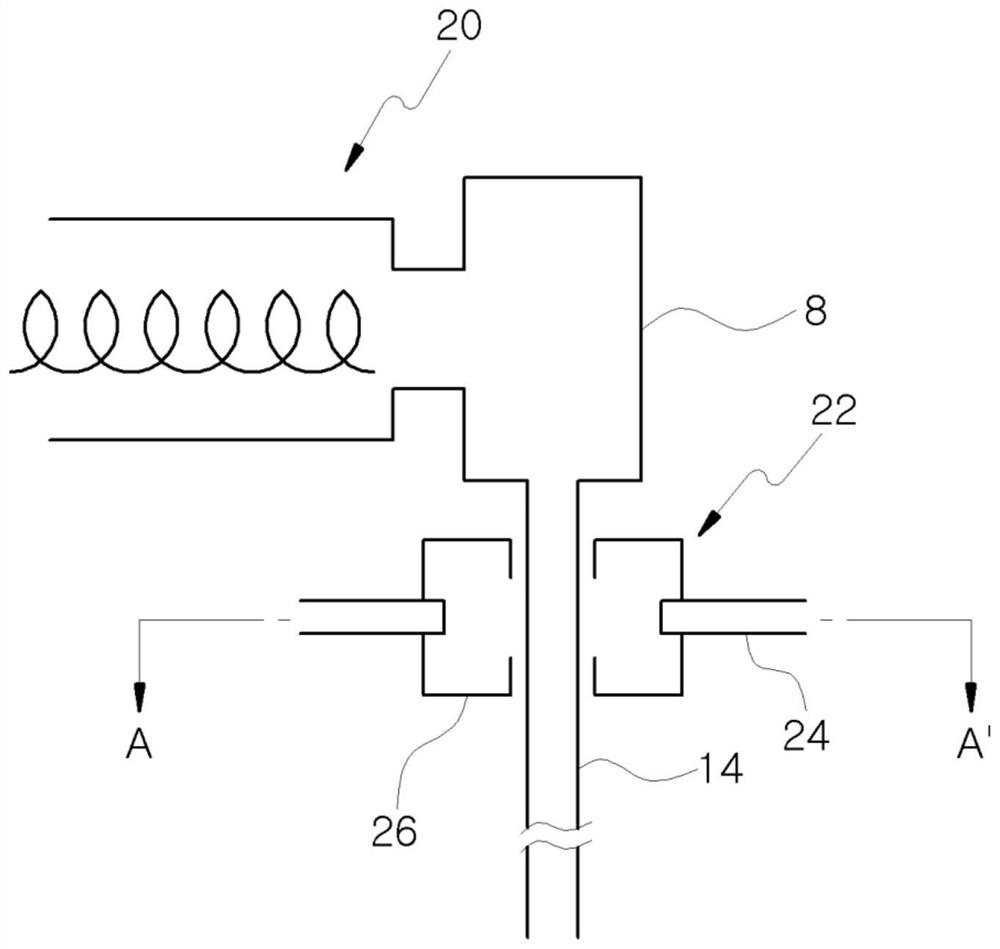

[0049] By applying a negative pressure intermittently to the suction line (32) through a suction device such as a compression surface (not shown), the suction can be sucked through the suction hole (34) and flow down from the inner wall of the jet restricting membrane (26). of release agent residue.

[0050] According to yet another embodiment of the present invention, there is provided a method of heating the spray limiting film (26) itself to vaporize the accumulated portion of the sprayed release agent limiting film (26) instantly. That is to say, if a heat wire (not shown) is installed on the predetermined part of the spray restricting film (26), and the heat is heated above the boiling point of the release agent, the residual amount of the sprayed release agent will contact the spray restricting film (26) and evaporate immediately. , and thus will not cause adverse phenomena.

[0051] In this method, the primary tube (14) can be cured to a certain extent by the heat of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com