Profile matching laying method for heat insulation layers

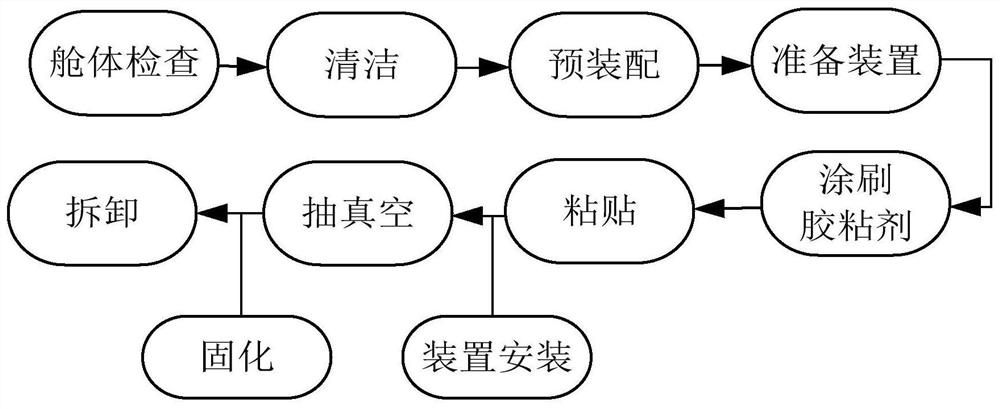

A heat insulation layer and surface matching technology, which is applied in the field of heat insulation layer surface matching laying, can solve the problems of uneven force, limited curing area, easy cracks, etc., achieve stable and reliable performance, and ensure heat insulation effect , highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, a single inner insulation layer is used to lay the cabin body, and the specific operations are as follows:

[0044] (1) Check the cabin body that needs to be laid with heat insulation layer, including structural integrity, wall flatness, etc. The volume of the cabin body is 0.8m 3 ; It is judged that the cabin and the heat insulation layer can be integrally installed in the vacuum auxiliary device, and the heat insulation layer can be laid;

[0045] (2) Clean the cabin body where the heat insulation layer needs to be laid, and ensure that the contact surface between the heat insulation layer and the cabin body is clean and free of oil stains;

[0046] (3) Prepare the single-block inner heat-insulation layer that needs to be laid, and the heat-insulation layer is made of flexible heat-insulation material, and then this heat-insulation layer and the cabin body are preassembled;

[0047] (4) Make a vacuum auxiliary device according to the size, shape a...

Embodiment 2

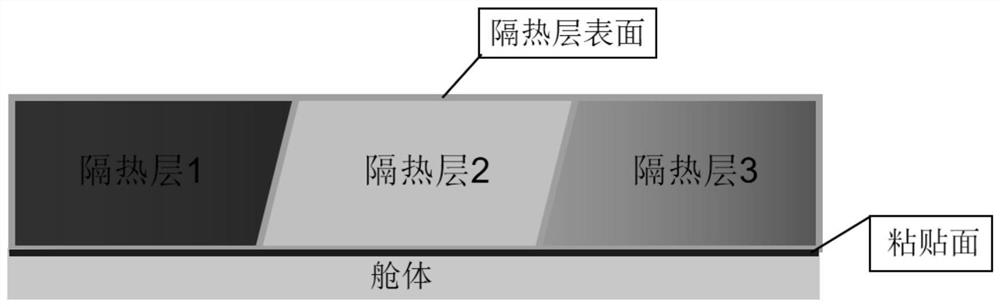

[0054] In this embodiment, 6 inner insulation layers are used to lay the cabin body, and the specific operations are as follows:

[0055] (1) Check the cabin body that needs to be laid with heat insulation layer, including structural integrity, wall flatness, etc. The volume of the cabin body is 2m 3 ; It is judged that the structure of the cabin can be used as a part of the vacuum auxiliary device, and the heat insulation layer can be laid;

[0056] (2) Clean the cabin body where the heat insulation layer needs to be laid, and ensure that the contact surface between the heat insulation layer and the cabin body is clean and free of oil stains;

[0057] (3) Prepare 6 inner heat insulation layers that need to be laid, and the heat insulation layer is made of flexible heat insulation material, and then the heat insulation layer and the cabin body are preassembled;

[0058] (4) Make a vacuum auxiliary device according to the size, shape and tightness of the cabin;

[0059] (5) App...

Embodiment 3

[0065] It is carried out in the same manner as in Example 1, except that the heat insulation layer is an outer heat insulation layer.

[0066] After testing, the compression force on each side of the heat insulation layer during the curing process and the bonding strength of each position of the heat insulation layer after curing are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com