Power battery mounting structure and vehicle

A technology of power battery and installation structure, applied in the direction of power unit, electric power unit, superstructure, etc., can solve the problems of high reliability, insufficient structural strength, insufficient depth of tire pool, etc. The effect of reducing development time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

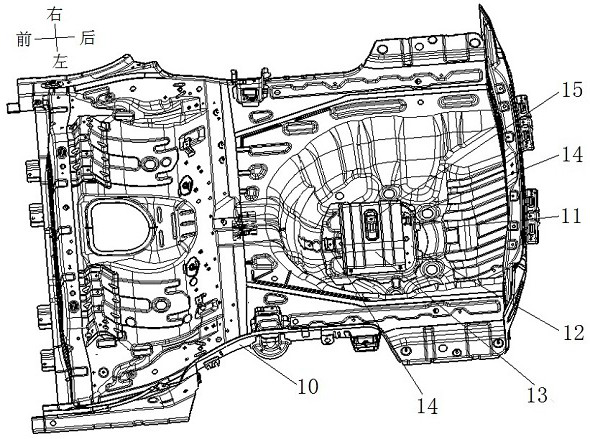

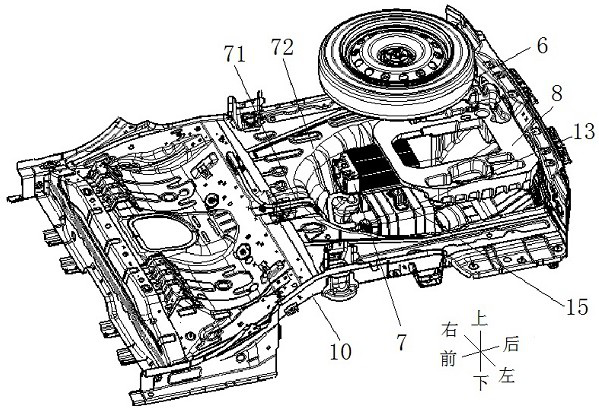

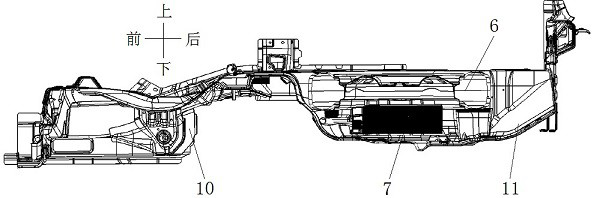

[0022] see Figure 4 and Figure 5 , the power battery installation structure shown includes a rear floor 1 and an installation box 2, the rear section of the rear floor 1 is recessed downwards to form a spare tire pool 11, the installation box 2 is fixed below the spare tire pool 11, and the installation box 2 There is an accommodation cavity inside, and an opening 21 communicating with the accommodation cavity is provided at the top. The opening 21 is provided with an overlapping flange 22 welded and fixed to the lower surface of the spare tire pool 11, in order to ensure the sealing of the accommodation cavity and prevent the outside Foreign matter enters, apply sealant 9 at the overlap between the installation box 2 and the spare tire pool 11, apply welding sealant on the inside of the overlap close to the accommodation cavity for sealing, and apply a coating on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com