Treatment method of chemical nickel plating waste liquid

A technology of electroless nickel plating and treatment method, applied in chemical instruments and methods, metallurgical wastewater treatment, oxidized water/sewage treatment, etc., can solve the problems of up to standard treatment, difficult treatment of chemical nickel plating, etc., and achieve the effect of efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Get 250 milliliters of electroless nickel-plating waste liquids respectively, element Ni is 3600mg / L in the waste liquid after measuring, and element P is 56400mg / L, and pH is 1.2. Add 50% sodium hydroxide to adjust the pH of the electroless nickel plating waste solution to 2, 4, 6, 7, 8, 9 respectively. Follow S 2- / Ni 2+ The molar ratio of the solution is 0.8:1. Sodium hydrosulfide is added to precipitate the nickel for the first time, and an appropriate amount of PAM is used to accelerate the coagulation. After the nickel sediment is separated from the solid and liquid by centrifugation, the residual nickel concentration in the solution is measured. The results are shown in Table 1.

[0039] Table 1 Residual nickel concentration after sodium hydrosulfide nickel precipitation under different pH conditions

[0040] pH 2 4 6 7 8 9 Residual nickel concentration mg / L 2970 1620 1180 797 708 555 Removal rate% 17.5 55.0 67.2 77.86 80.3 ...

Embodiment 2

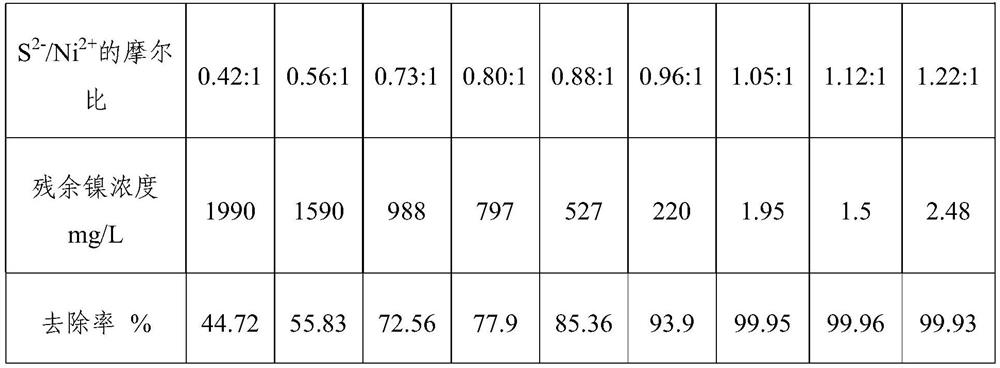

[0043] Get 250 milliliters of electroless nickel-plating waste liquids respectively, element Ni is 3600mg / L in the waste liquid after measuring, and element P is 56400mg / L, and pH is 1.2. Add 50% sodium hydroxide to adjust the pH of the electroless nickel plating waste solution to 7. Follow S 2- / Ni 2+ The molar ratios are 0.42:1, 0.56:1, 0.73:1, 0.80:1, 0.88:1, 0.96:1, 1.05:1, 1.12:1, 1.22:1, add sodium hydrogen sulfide to make the initial precipitation of nickel and use An appropriate amount of PAM was used to accelerate the coagulation, and after the nickel sediment was separated from solid and liquid by centrifugation, the residual nickel concentration in the solution was measured. The results are shown in Table 2.

[0044] Table 2 The relationship between the amount of sodium hydrosulfide added and the concentration of residual nickel under the condition of pH 7

[0045]

Embodiment 3

[0047] Get 250 milliliters of electroless nickel plating waste liquids respectively, element Ni is 5000mg / L in the waste liquid after measuring, element P is 50000mg / L, and pH is 4.0. Add 50% sodium hydroxide to adjust the pH of the electroless nickel plating waste solution to 7.0. Follow S 2- / Ni 2+ The molar ratio of the solution is 1:1, sodium hydrosulfide is added to precipitate the nickel for the first time, and an appropriate amount of PAM is used to accelerate the coagulation. After the nickel sediment is separated from the solid and liquid by centrifugation, the residual nickel concentration in the solution is measured. Then add an appropriate amount of ethyl disulfide nitrogen, the solution becomes colorless, the second step of nickel precipitation and the second solid-liquid separation. The high phosphorus-containing organic acid solution after nickel removal was vacuum evaporated and concentrated to a solid content of 50%. Take 2.0 g of the concentrated high-phos...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap