A kind of upper formation anti-slump drilling fluid and preparation method thereof

A drilling fluid and formation technology, which is applied in the field of upper formation anti-slump drilling fluid and its preparation, can solve the problems of poor plugging inhibition ability and poor effect of low free water drilling fluid, and achieves convenient preparation and maintenance, and filtration loss. Low and stable borehole wall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] After mixing, preferably cooling, the polymeric alcohol is added.

[0052] After the reaction, drying is performed to obtain a blocking and anti-collapse inhibitor; the drying is preferably vacuum drying.

[0055] The quality of the stabilizer is preferably 0.4% to 0.8% of the quality of the upper formation anti-slump drilling fluid, more preferably

[0056] The quality of the tackifier is preferably 1.5% to 2.5% of the quality of the upper formation anti-collapse drilling fluid, more preferably

[0063] The preparation process of the upper formation anti-slump drilling fluid provided by the present invention is simple.

Embodiment 1

[0077] FIG. 1 is a photograph of the plugging anti-slump inhibitor obtained in Example 1.

[0080]

[0084]

[0087] S

[0091]

[0092]

[0094] The rock sample recovery rate experiment: mainly determine the particle size of the rock sample with a particle size of 6 mesh to 10 mesh (2.0 to 3.2 mm) in 350 mL of solution

[0096]

Embodiment 2

[0100] 4% sodium soil+1% plugging anti-slump inhibitor GFJ (prepared in Example 1)+1% ammonium salt+2% carboxymethyl starch CMS+

[0101] Plugging and anti-collapse inhibitor GFJ performance index: API fluid loss: 12.4ml; Penetration: 0.23mm; Particle size after hot rolling:

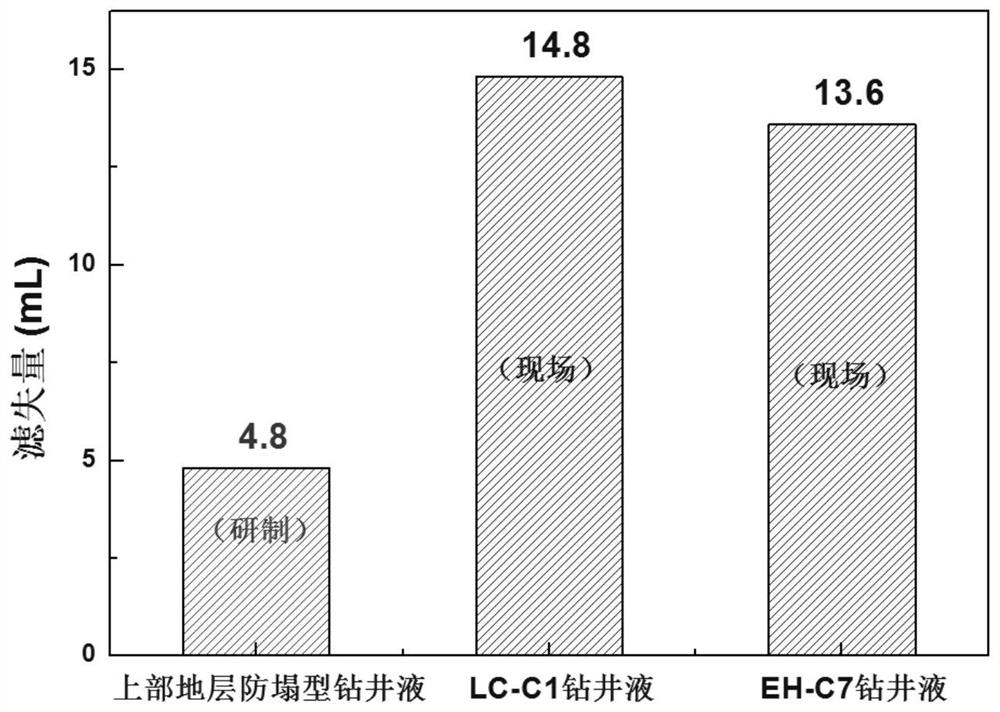

[0112] Conventional performance evaluation The conventional performance evaluation results of the upper formation anti-slump drilling fluid are shown in Table 5. The results show that the drill

[0114]

[0118]

[0119] The results show that the system has a good effect of inhibiting the dispersion of cuttings, and the recovery rate of rock samples exceeds 98.0%.

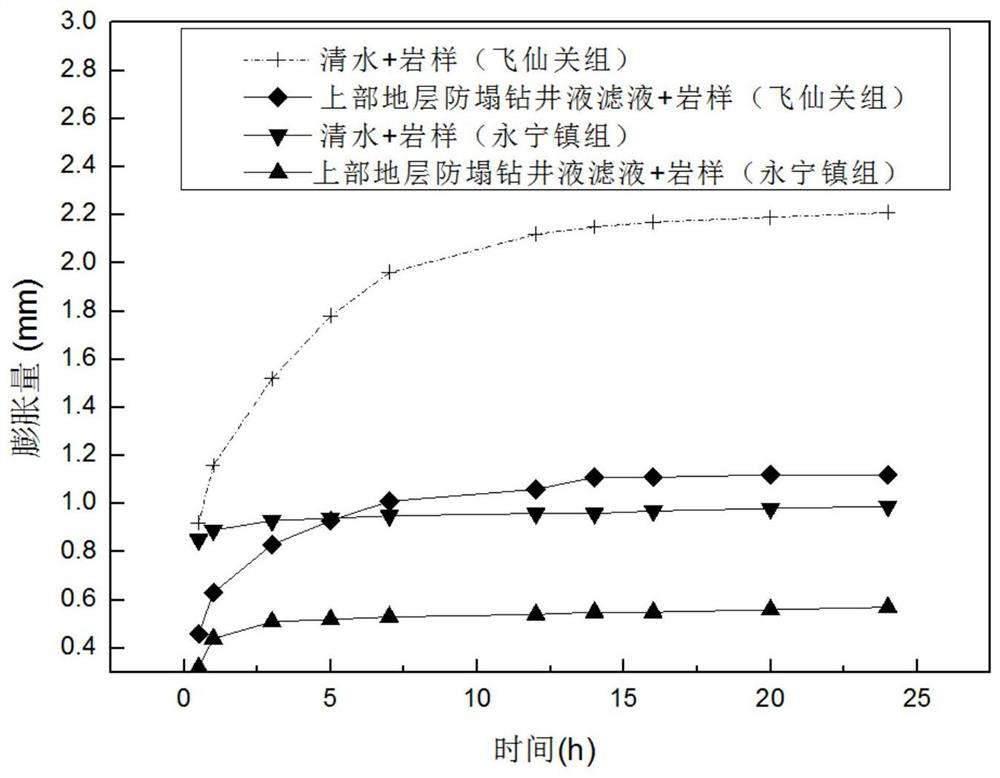

[0120] Expansion experiment of rock sample

[0123]

[0125] Debris invasion experiment

[0128]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com