Coal gangue yard smoldering fire area full-surrounding fire extinguishing treatment method

A coal gangue and full-surrounding technology, which is applied in the fields of earthwork drilling, safety devices, fire prevention, etc., can solve the problem of high cost of using new grouting materials, failure of grouting to form effective inclusions and coverings, extinction and recombustion, etc. problems, to achieve the effect of eliminating threats, effectively extinguishing fires and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

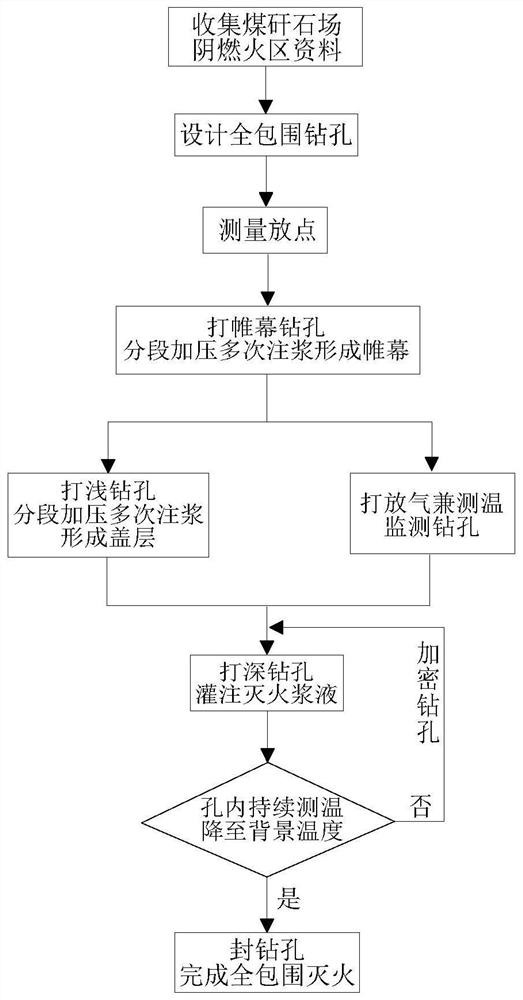

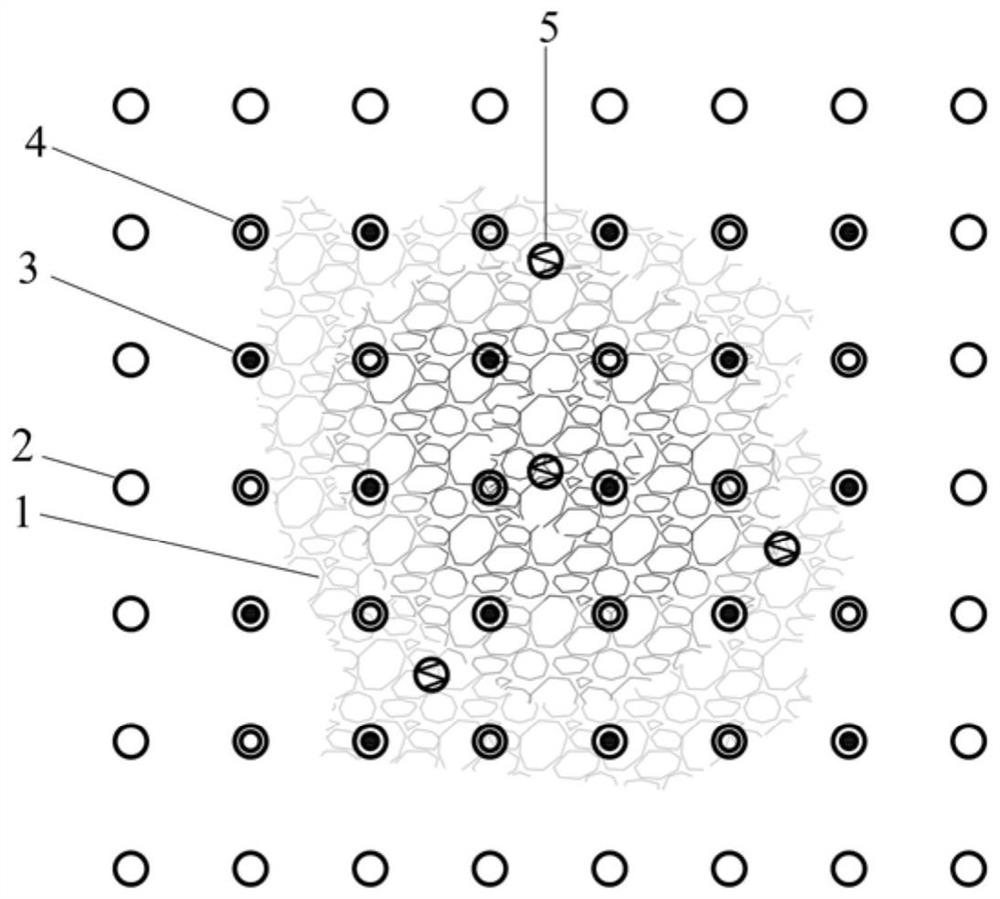

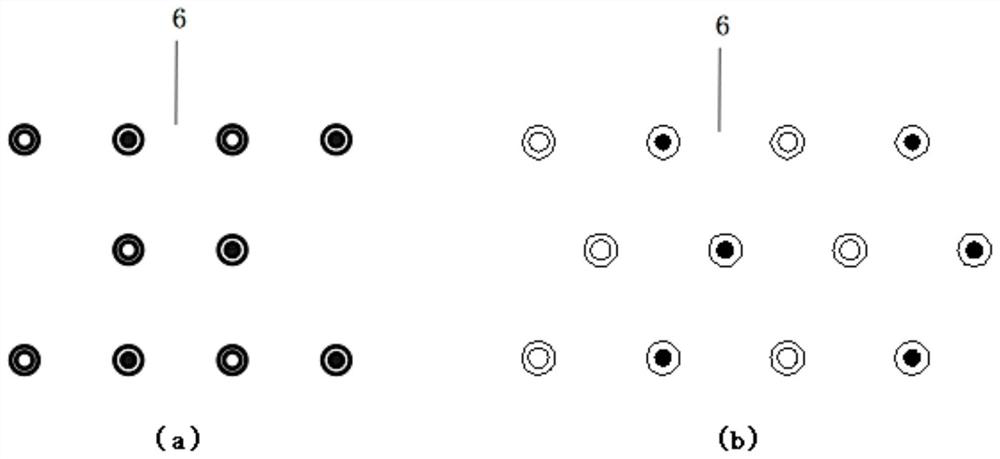

[0060] This embodiment provides a kind of coal gangue field smoldering fire area 1 surround fire extinguishing management method, such as Figure 1 to Figure 3 As shown, curtain boreholes 2 are arranged around the smoldering fire area 1 of the coal gangue field and a one-way grouting pipe 7 is placed, and a curtain 14 is formed by segmental pressurization and multiple grouting; the curtain formed by the curtain boreholes 2 Shallow boreholes 3 and deep boreholes 4 are arranged at intervals in the area, and one-way grouting pipe 7 is embedded in the shallow boreholes 3, and the grouting cover 15 is formed by segmental pressurization and multiple grouting, which encloses and covers the fire area with the curtain 14; The grouting flower tube 12 is inserted into the borehole 4, and the grouting fully fills the gaps in the fire area to complete the grouting of the coal gangue; and the gas release and temperature measurement borehole 5 is left in the curtain area during the treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com