Water-cooled fuel gas sampling rake

A water-cooled, gas-fired technology, applied in sampling, sampling devices, measuring devices, etc., can solve problems affecting accuracy, affecting the original structure of the flow field, and high demand for fine control, so as to prevent deviation and improve heat transfer efficiency , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

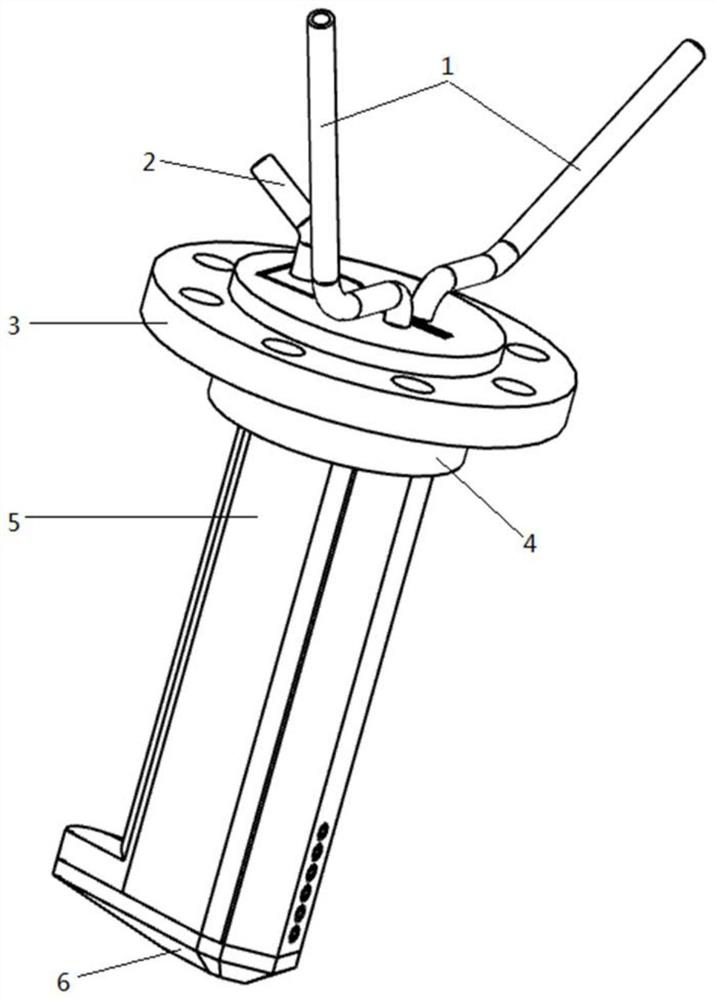

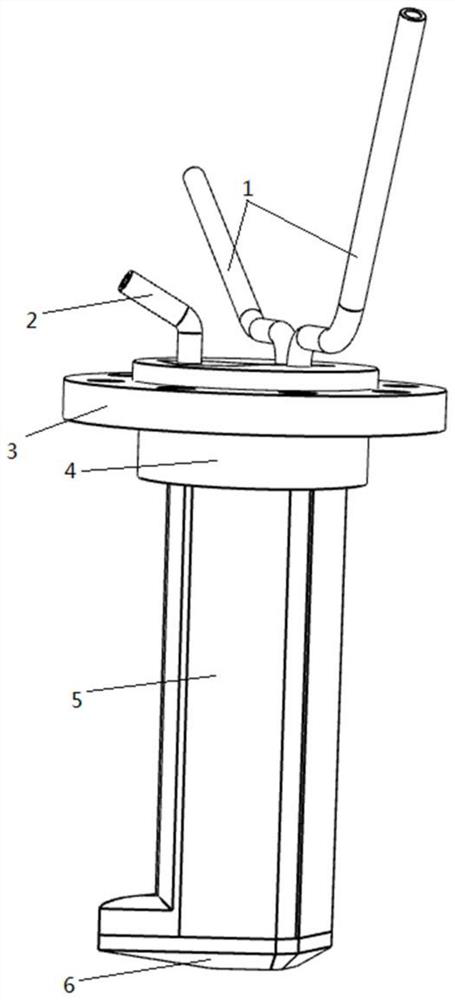

[0036] A water-cooled gas sampling rake, the overall structure is as follows figure 1 and figure 2 As shown, it includes: sampling section, cooling pipeline 1, sample gas pipeline 2, and mounting flange 3. The cooling pipeline 1 and the sample gas pipeline 2 are connected to the sampling section. The coolant enters the sampling section through the cooling pipeline 1. The collected high-temperature flue gas is transmitted to the flue gas analysis equipment through the sample gas pipeline 2. The mounting flange 3 is fixed on the sampling section. On the section, a sampling hole 54 is provided on the sampling section, and the sampling section includes: a mixing section 4 , a measuring section 5 , and a wedge-shaped bottom 6 .

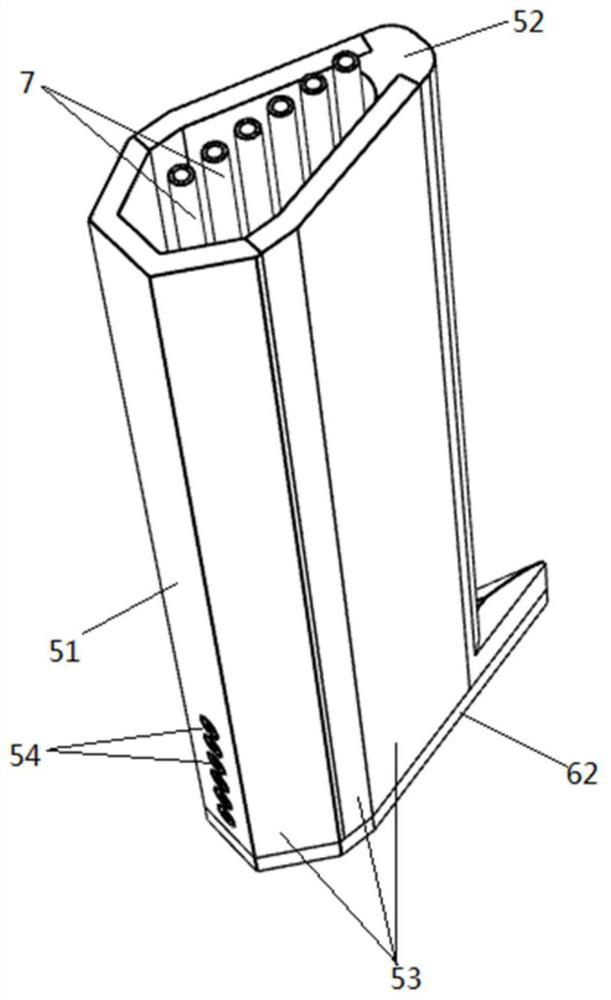

[0037] Specifically, the bottom of the measuring section 5 is integrally formed with the wedge-shaped bottom 6 .

[0038] Such as image 3 As shown, the measurement section 5 is a hollow prism structure, including a windward surface 51, a leeward surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com