Cargo management system and method

A management system and management method technology, applied in the field of cargo management, can solve problems such as unfavorable unified management, inability to realize paperless cargo management, and easy loss of relevant information, so as to facilitate unified management, avoid manual recording of cargo information, and avoid loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

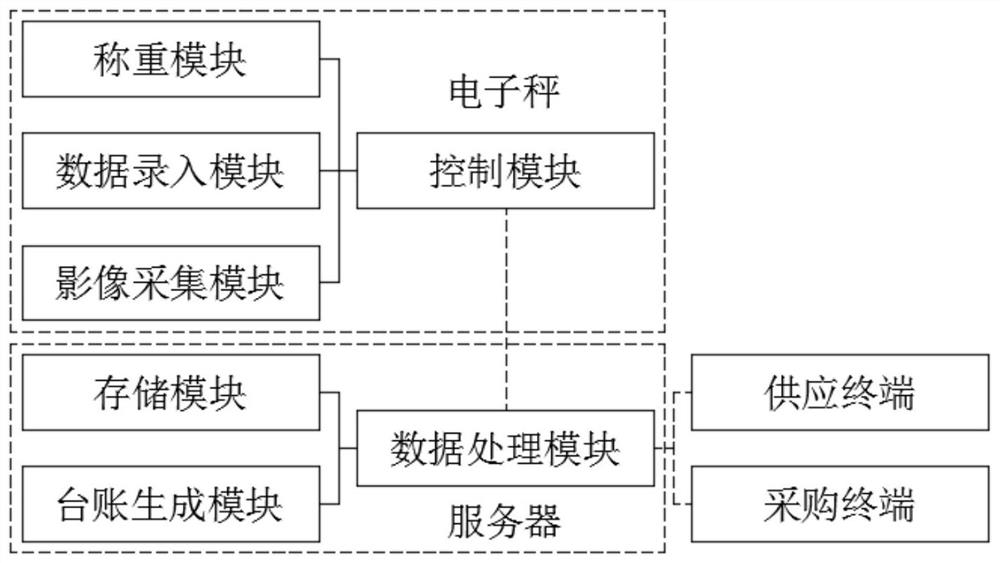

[0051]This embodiment provides a cargo management system, such asfigure 1 As shown, it includes an electronic scale and a server, and the electronic scale includes a control module, a weighing module and an information entry module;

[0052]The control module is used to receive the warehousing information or the warehousing information, and then send the warehousing information or the warehousing information to the server. The warehousing information includes the warehousing date, supplier information, inspector information, purchaser information, and custodian information Information about the goods in and out of the warehouse. The outgoing information includes the out date, outgoing person information, picker information, purchaser information, custodian information, and outgoing goods information. The incoming goods information and outgoing goods information include the weight of the goods. Information and / or cargo quantity information; among them, the storage date defaults to the c...

Embodiment 2

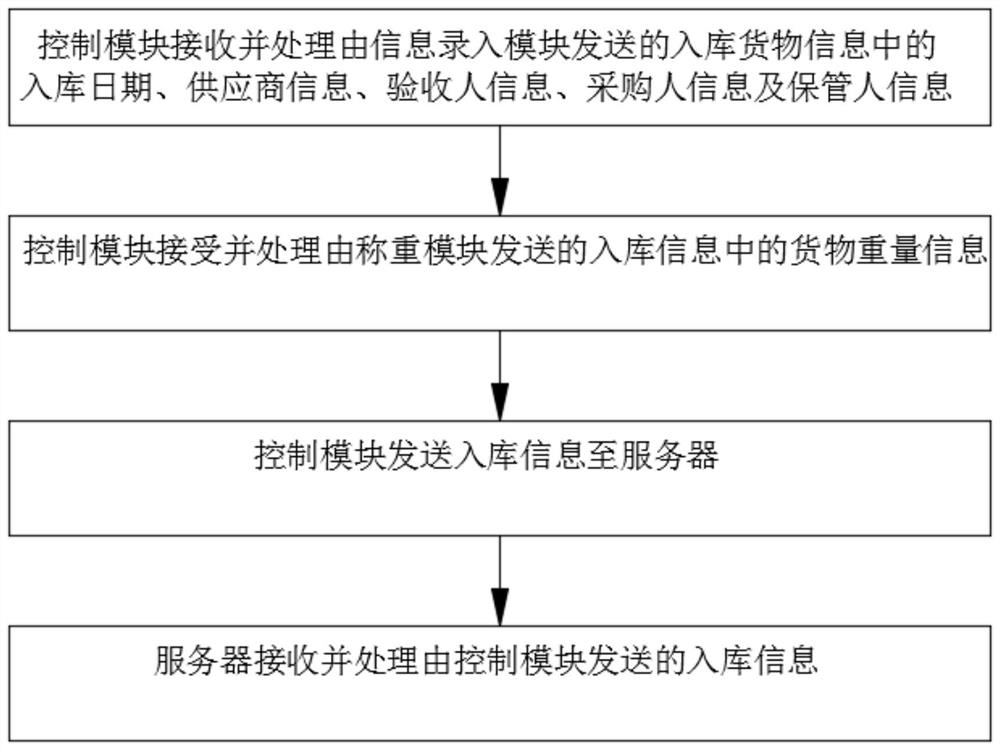

[0076]This embodiment discloses a cargo management method, which is implemented based on the cargo management system in any one of Embodiment 1. The cargo management method includes an inbound method and an outbound method;figure 2 As shown, the warehousing method includes the following steps:

[0077]The control module receives and processes the warehousing date, supplier information, inspector information, purchaser information and custodian information in the warehousing information sent by the information entry module;

[0078]The control module accepts and processes the cargo weight information in the warehousing information sent by the weighing module;

[0079]The control module sends the storage information to the server;

[0080]The server receives and processes the warehousing information sent by the control module;

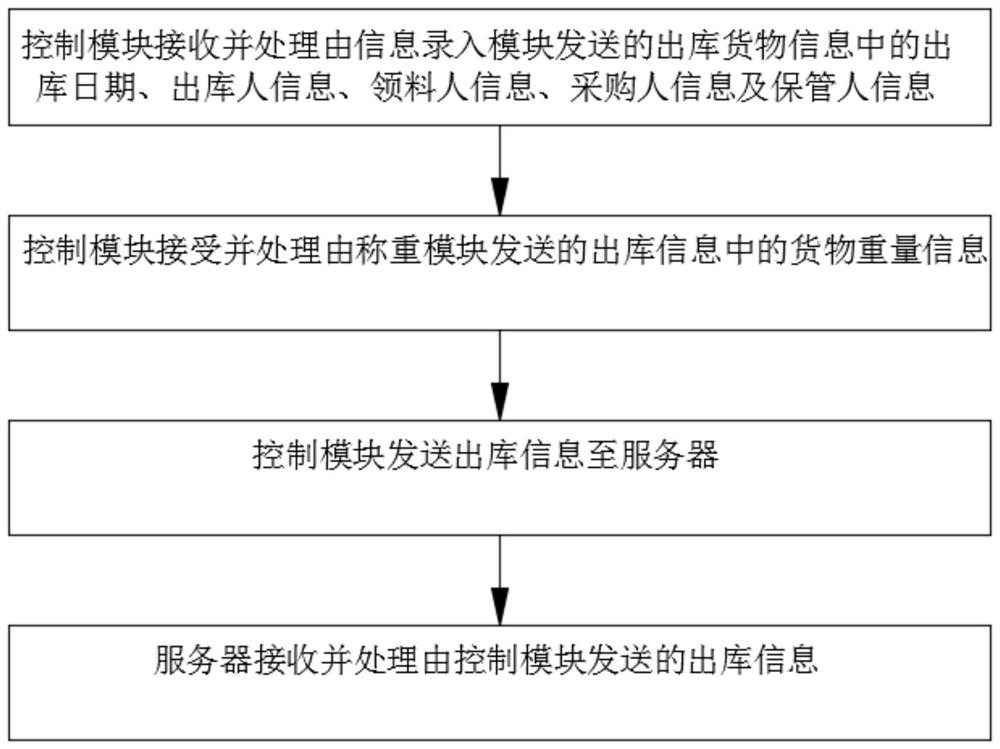

[0081]Such asimage 3As shown, the outbound method includes the following steps:

[0082]The control module receives and processes the outgoing date, outgoing person information...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com