Urban underground pipeline spraying anti-corrosion device

A technology for underground pipelines and anti-corrosion devices, which is applied in the direction of spraying devices, can solve the problems of thickness effect of spraying, poor spraying effect, perishability, etc., and achieves the effect of ensuring uniformity, realizing automatic adjustment and good spraying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

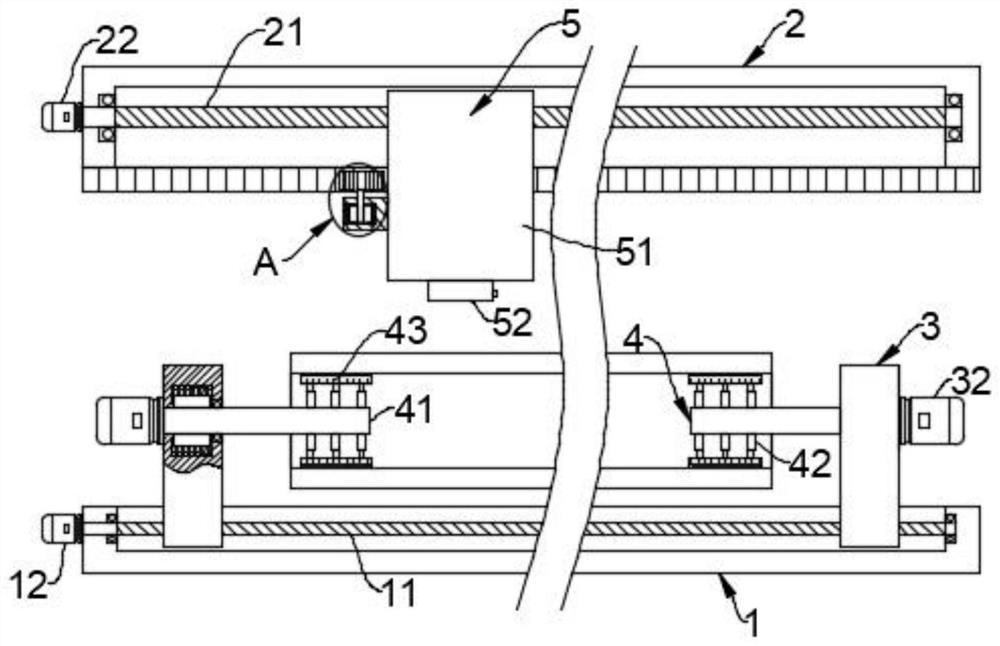

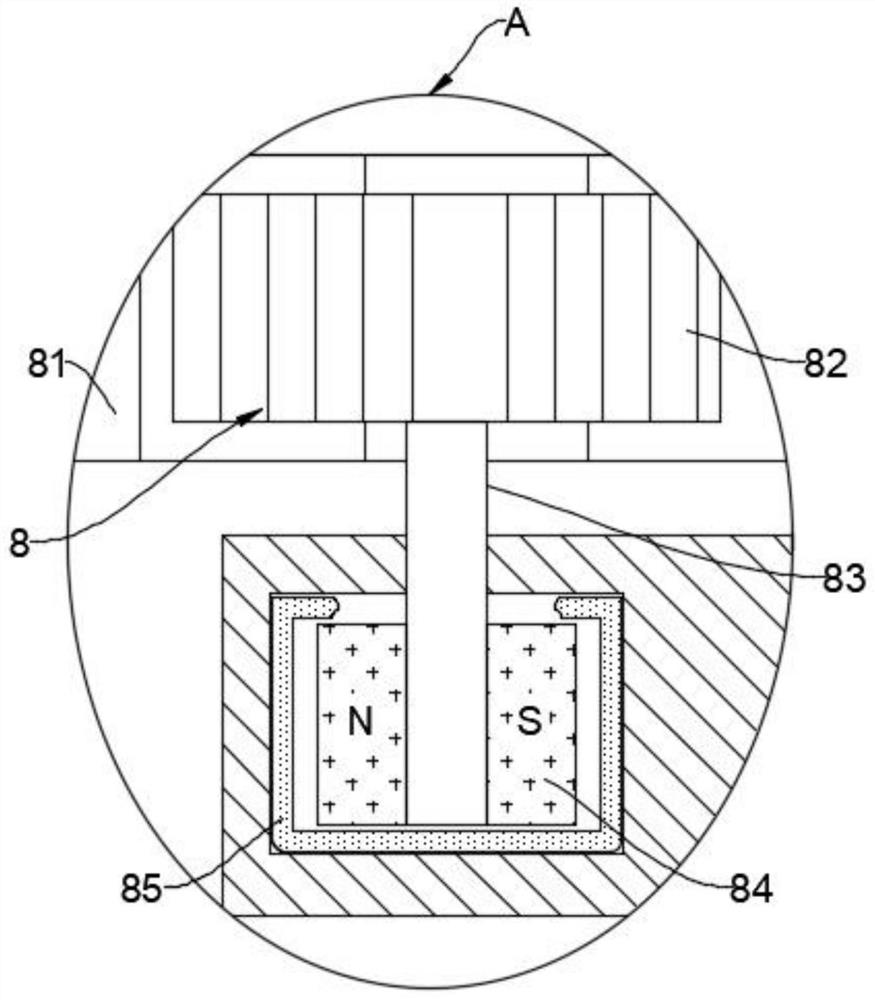

[0023] Such as Figure 1-6 As shown, an urban underground pipeline spraying anti-corrosion device includes a lower moving track 1 and an upper moving track 2 .

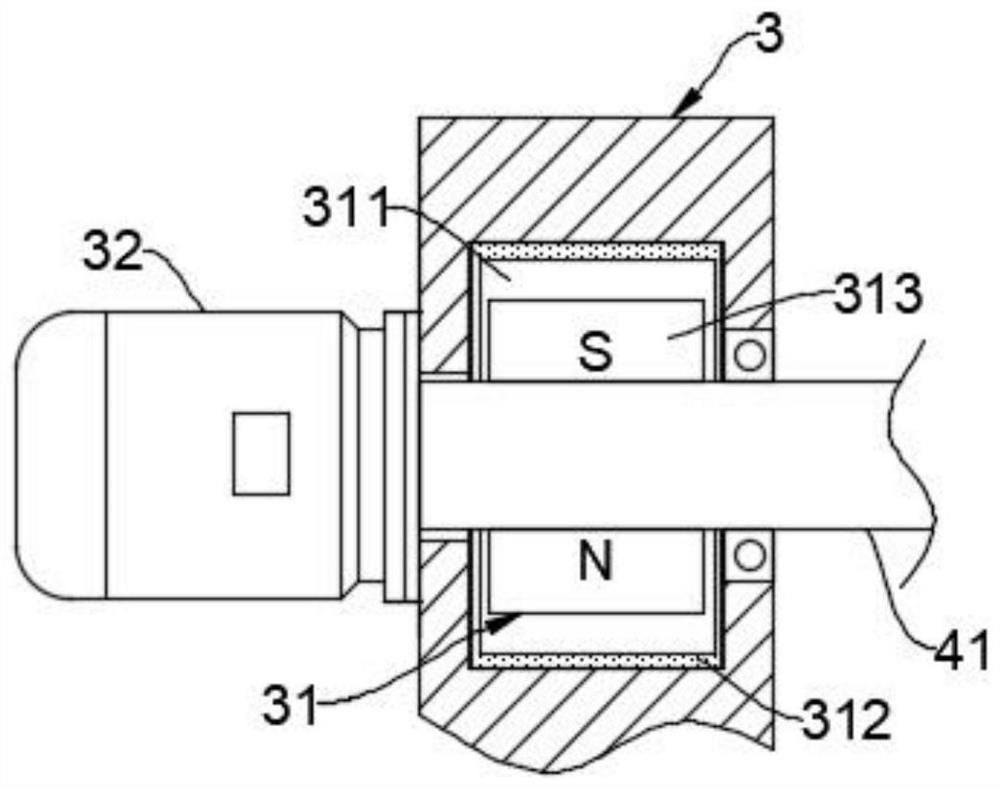

[0024] The lower moving track 1 is provided with two opposite moving seats 3, and the lower moving track 1 is rotatably connected with two first ball screw screws 11, the moving seat 3 slides on the lower moving track 1, and the two first ball screws The bar 11 is threadedly connected with the two moving seats 3 respectively, and the first ball screw 11 is fixedly connected with the output end of the first motor 12 fixed on the lower moving track 1 .

[0025] The first motor 12 can be used to drive the first ball screw 11 fixedly connected thereto to rotate, and then the rotation of the first ball screw 11 can drive the moving seat 3 to slide on the lower moving track 1 .

[0026] Such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com