A kind of preparation method of cemented carbide saw blade

A technology of cemented carbide and saw blades, which is applied in the field of preparation of cemented carbide saw blades, can solve the problems of high price, low efficiency of hot pressing and sintering process, high production and raw material costs, and achieve low raw material costs and high bending strength , The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

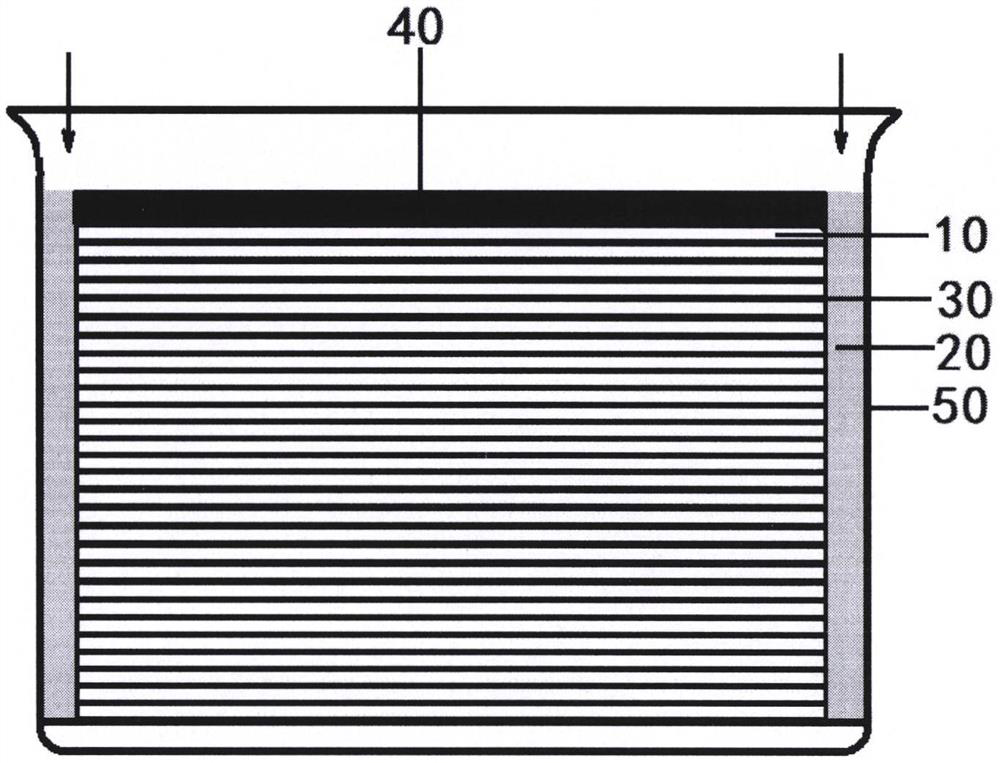

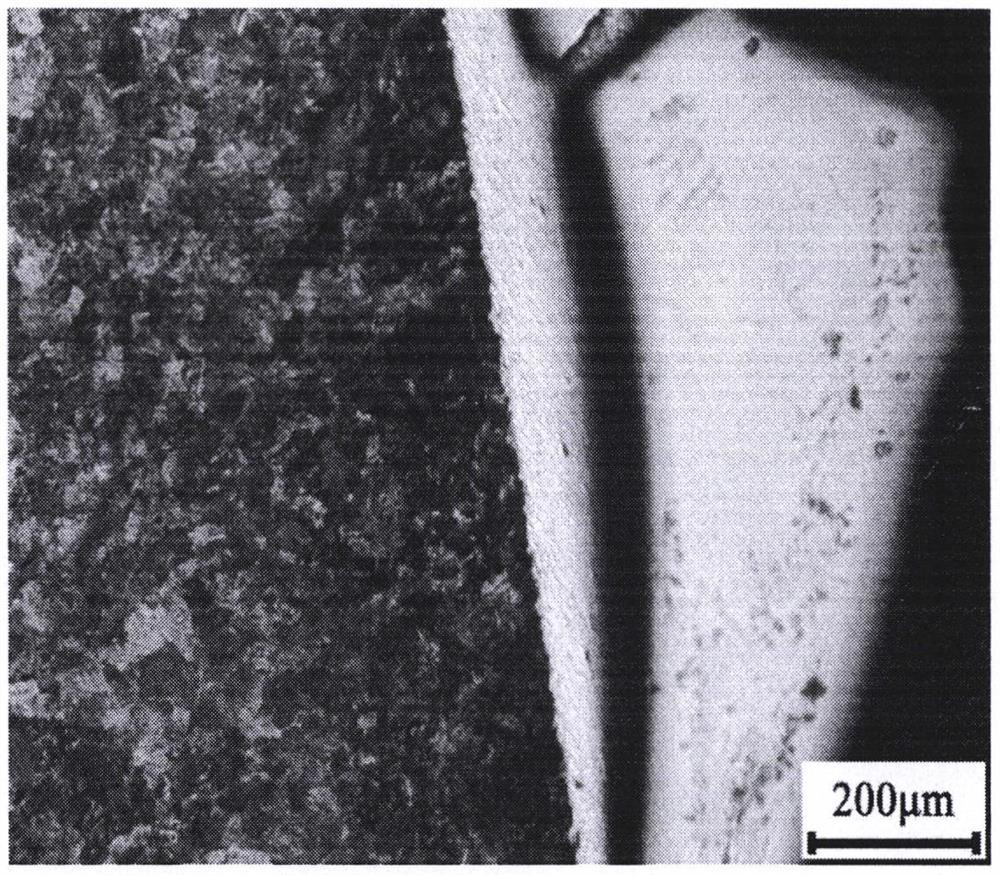

Embodiment 1

[0026] This embodiment relates to the preparation of a cemented carbide saw blade. 65Mn steel is used as the base of the saw blade. The base of the saw blade is circular with a diameter of 180mm and a thickness of 2mm. A shaft hole can be opened in the center of the base of the saw blade. The diameter of the shaft hole can be 22mm. In addition, the base of the saw blade can also be opened There are cooling holes etc. Prepare a graphite mold with an inner diameter of 185mm and a graphite gasket with a diameter of 180mm, and the thickness of the graphite gasket is 1mm. In the graphite mold, the above-mentioned 65Mn steel substrate 10 and graphite gaskets are stacked sequentially along the height direction to form a stacked structure, and a graphite cap is set on the stacked structure as a casting protection device, and the gap between the stacked structure and the graphite mold is filled. Tungsten alloy steel fragments. Before casting, the graphite mold is first heated to 900°...

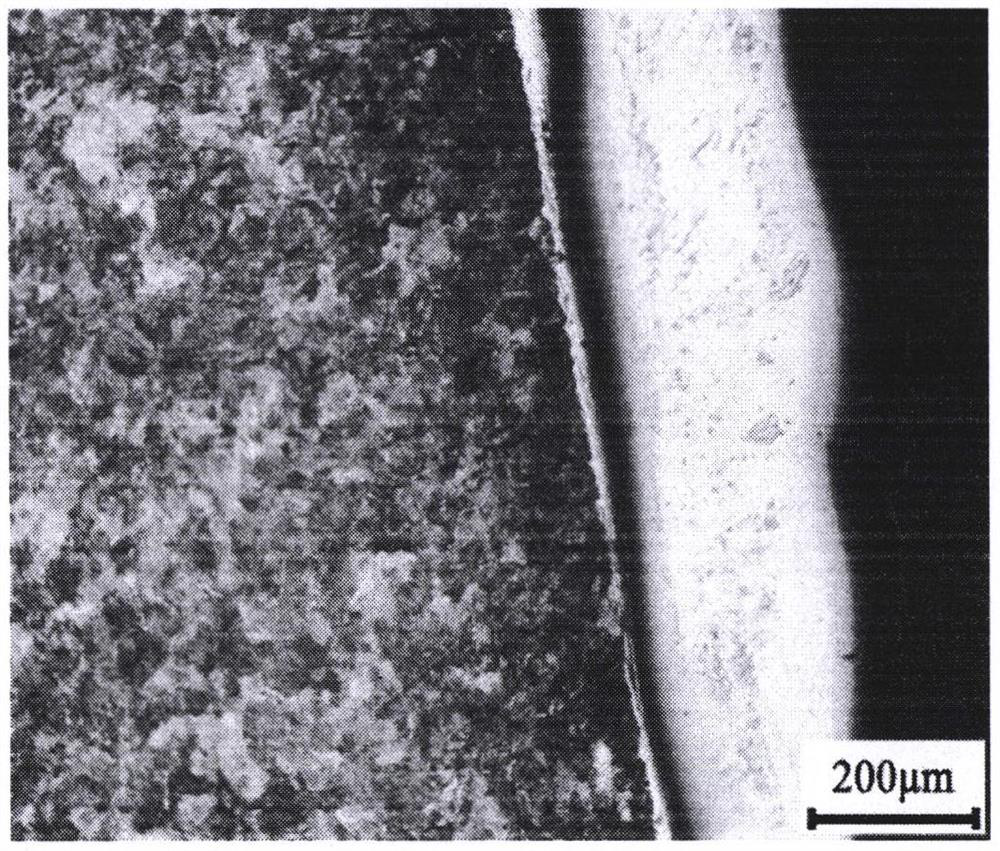

Embodiment 2

[0028]This embodiment relates to the preparation of a cemented carbide saw blade. 65Mn steel is used as the base of the saw blade. The base of the saw blade is circular with a diameter of 180mm and a thickness of 2mm. A shaft hole can be opened in the center of the base of the saw blade. The diameter of the shaft hole can be 22mm. In addition, the base of the saw blade can also be opened There are cooling holes etc. Prepare a graphite mold with an inner diameter of 185mm and a graphite gasket with a diameter of 180mm, and the thickness of the graphite gasket is 1mm. In the graphite mold, the above-mentioned 65Mn steel substrate 10 and graphite gaskets are stacked sequentially along the height direction to form a stacked structure, and a graphite cap is set on the stacked structure as a casting protection device, and the gap between the stacked structure and the graphite mold is filled. Tungsten alloy steel fragments. Before casting, the graphite mold is first heated to 900°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com