Hot runner oil cylinder cooling structure and mounting method thereof

A technology of cooling structure and hot runner, which is applied in the cooling field of hot runner of injection mold, can solve the problems of easy failure of water cooling, achieve the effect of reducing processing accuracy and avoiding extrusion deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following specific implementation methods are used to explain the technical solutions of the claims of the present invention, so that those skilled in the art can understand the claims. The protection scope of the present invention is not limited to the following specific implementation structures. The protection scope of the present invention includes the technical solution of the claims of the present invention made by those skilled in the art and is different from the following specific embodiments.

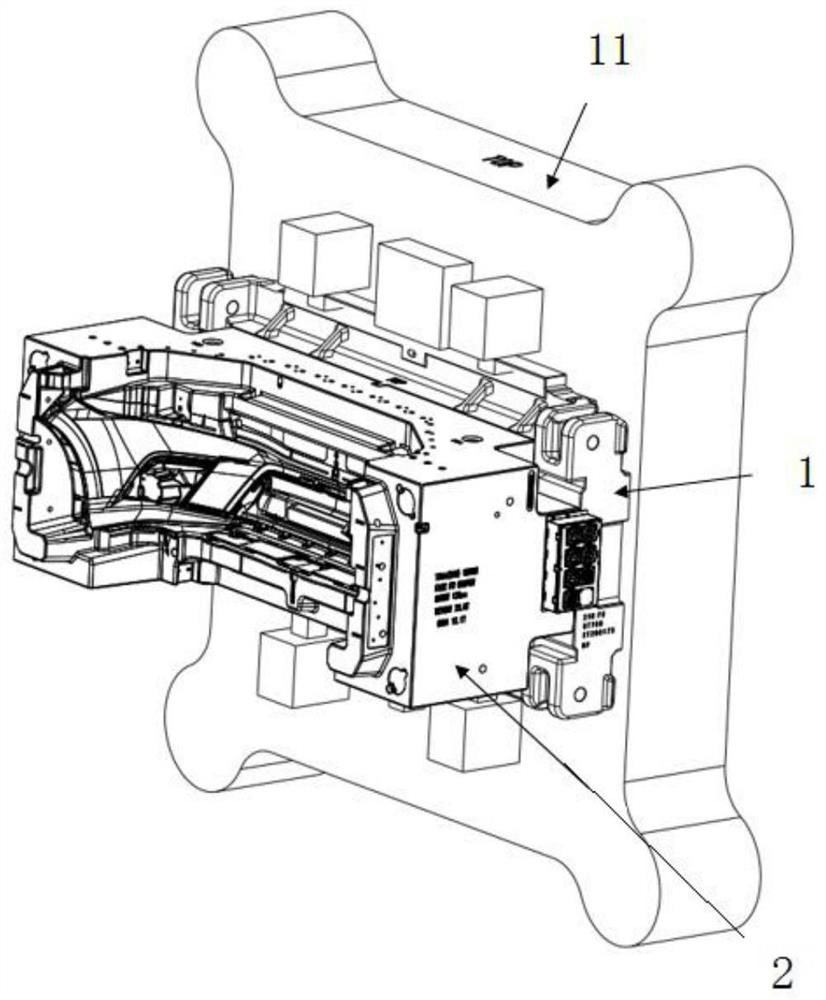

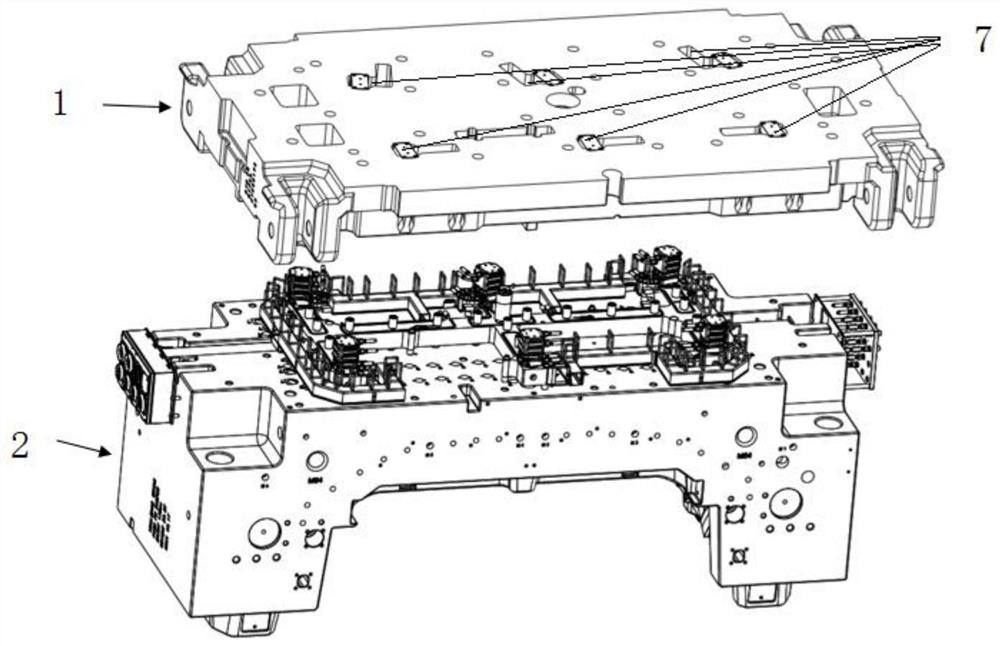

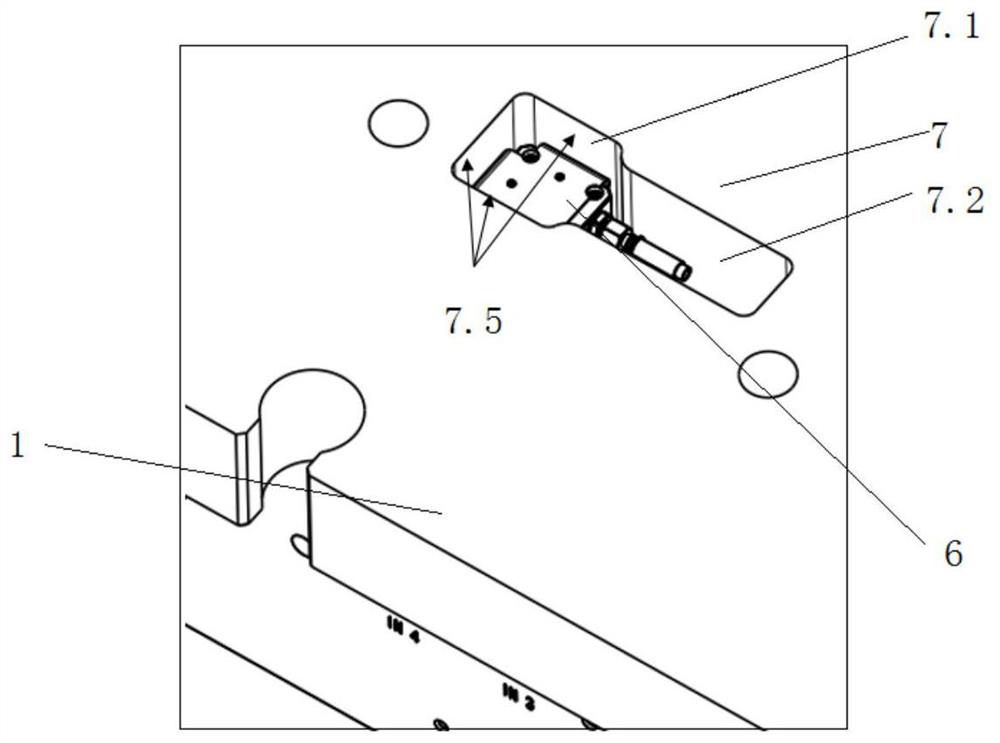

[0023] Such as Figure 1-3 As shown, the connecting plate 1 is connected to the injection molding cavity 2, and a hot runner is provided between the connecting plate 1 and the injection molding cavity 2, and the valve pin controlling the hot runner is connected to the piston rod of the oil cylinder 6 (not shown in the prior art figure) . The connecting plate 1 is made of cast iron, also known as cast iron plate. The connecting plate 1 is fixedly connected and bon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com