Manufacturing equipment of all-plastic-package super-cork composite board for curved surface decoration

A technology for manufacturing equipment and composite boards, which is applied in the direction of manufacturing tools, lamination devices, wood processing appliances, etc., can solve the problems of all-plastic wrapping of cork composite boards, poor anti-corrosion and moisture-proof effect, etc., to reduce manual operations and facilitate blanking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

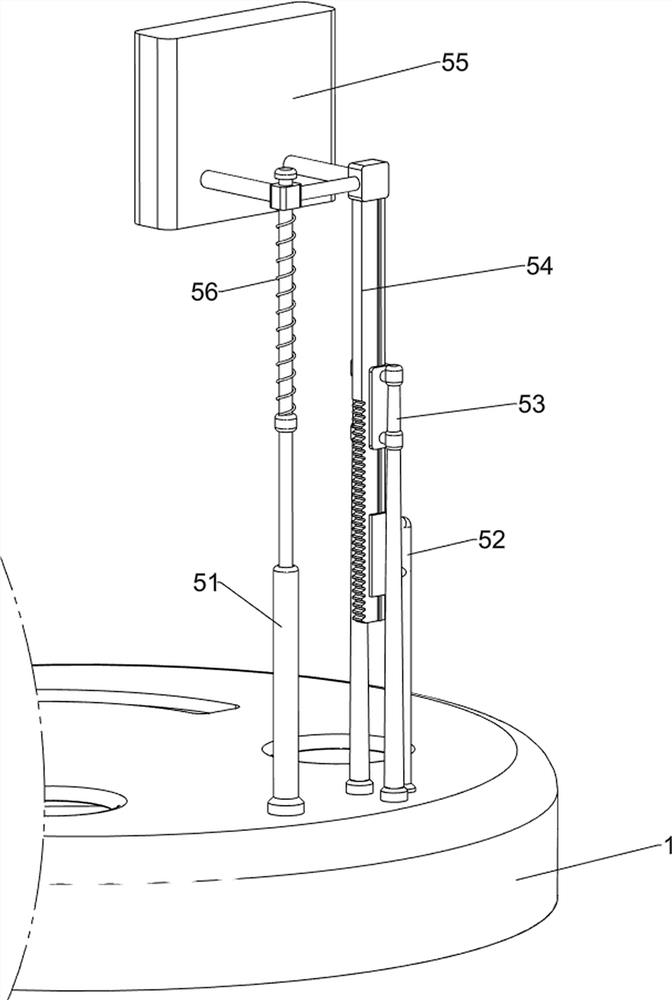

[0067] A kind of manufacturing equipment for all-plastic-coated ultra-cork composite boards for curved surface decoration, such as figure 1 As shown, it includes a base 1, a first rotating shaft 2, a connecting rod 3, a clamping mechanism 4 and a material spraying mechanism 5. The base 1 is provided with a first rotating shaft 2 in the middle of rotation, and the upper part of the first rotating shaft 2 is provided with a connecting rod 3. , the connecting rod 3 is provided with a clamping mechanism 4, and the rear side of the base 1 is provided with a spraying mechanism 5.

[0068]When the decoration workers need to fully plastic-wrap the cork composite board, they can use this kind of all-plastic-wrapped ultra-cork composite board manufacturing equipment. First, the composite board is placed on the clamping mechanism 4 for clamping, and then the first rotating shaft is rotated intermittently. 2, thereby driving the connecting rod 3 to rotate, and then driving the clamping me...

Embodiment 2

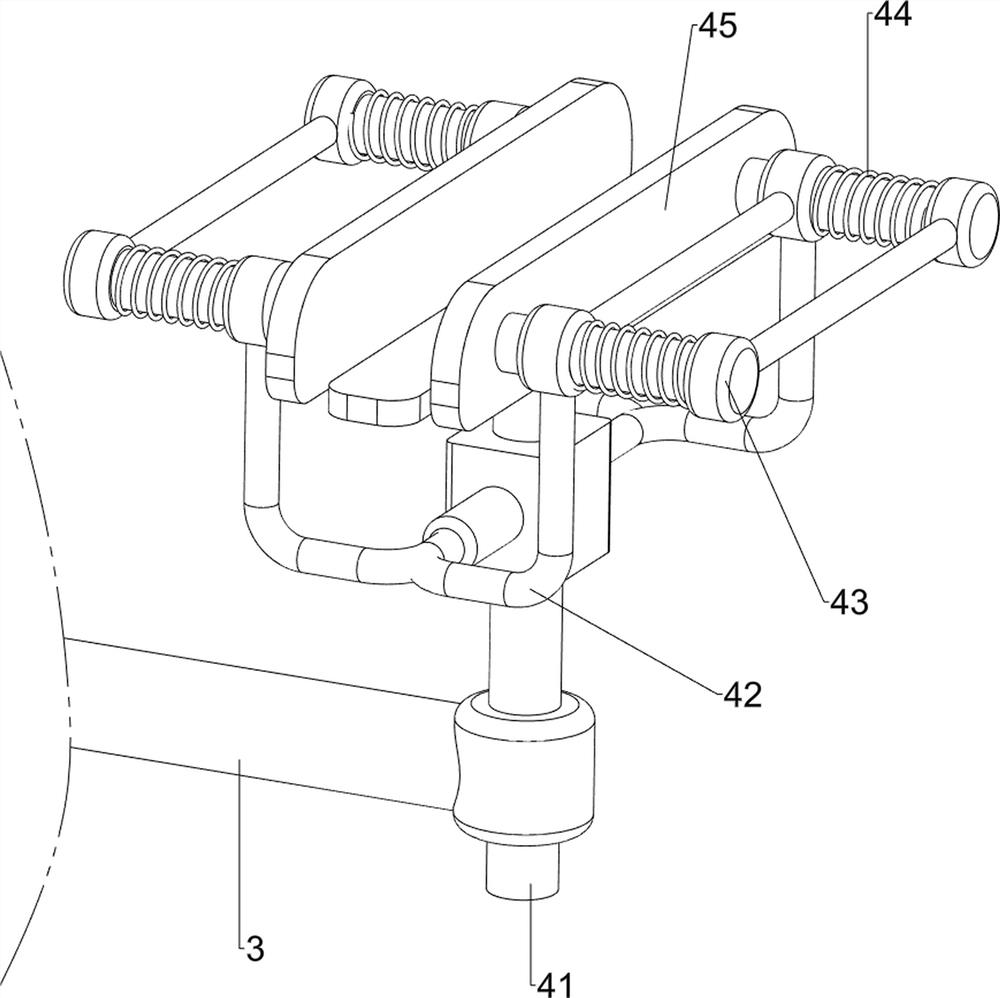

[0070] On the basis of Example 1, such as figure 2 and image 3 As shown, the clamping mechanism 4 includes a rotating column 41, a sliding sleeve 42, a first slide bar 43, a first spring 44 and a clip block 45, and the connecting rod 3 is uniformly rotated to be provided with four rotating columns 41, and the four rotating Column 41 tops are provided with sliding sleeves 42, and the tops of the four sliding sleeves 42 are all slidingly symmetrically provided with first slide bars 43, and each first slide bar 43 is wound with two first springs 44. The first springs 44 Both ends are respectively connected to the first sliding rod 43 and the sliding sleeve 42 , and each first sliding rod 43 is provided with a clamping block 45 inside.

[0071] The workers evenly place the four composite boards to be fully plastic-wrapped between the clamping blocks 45, the first slide bar 43 is adaptively slid outward, and the first spring 44 is adaptively compressed to achieve the effect of c...

Embodiment 3

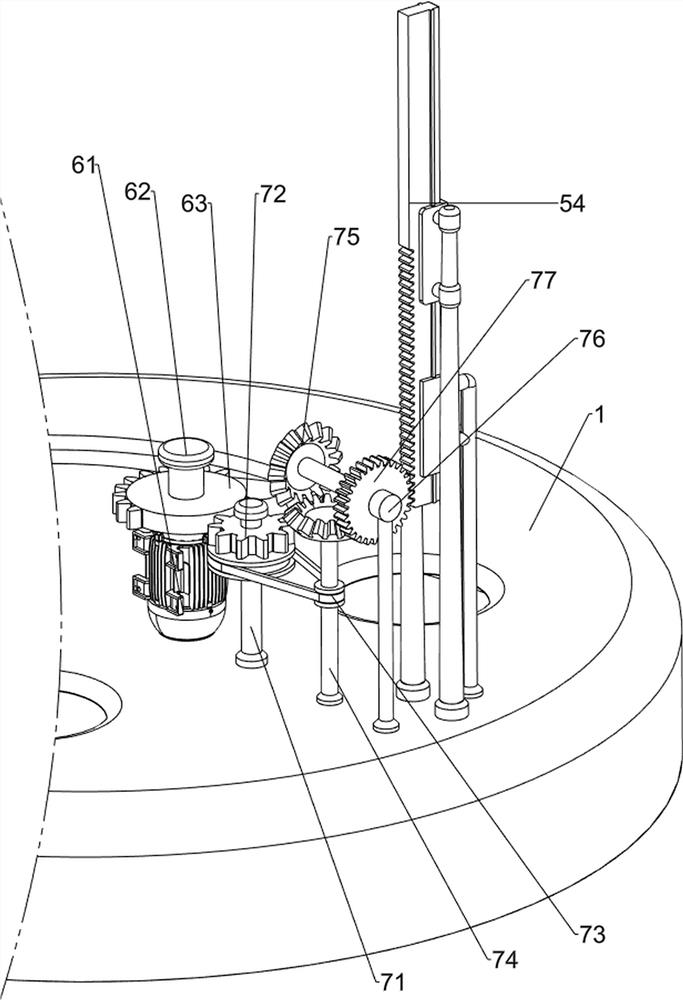

[0075] On the basis of Example 2, such as Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a rotating mechanism 6 is also included, and the base 1 is provided with a rotating mechanism 6 in the middle. 61, the output shaft of the motor 61 is provided with a second rotating shaft 62, the second rotating shaft 62 is provided with a sector gear 63, the lower part of the first rotating shaft 2 is provided with a first spur gear 64, and the first spur gear 64 and the sector gear 63 are intermittently meshed .

[0076] Start the motor 61, the rotation of the output shaft of the motor 61 drives the second rotating shaft 62 to rotate, thereby driving the sector gear 63 to rotate, and the sector gear 63 meshes with the first straight gear 64 intermittently so that the first straight gear 64 rotates, thereby driving the first rotating shaft 2 to rotate , to reduce the operation of turning the first rotating shaft 2 manually, and it is only necessary to turn off the motor 61...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap