NTC thermosensitive resistor and manufacturing method thereof

A thermistor, the main component technology, applied in the direction of resistors, resistors, non-adjustable metal resistors, etc., can solve the problems of reducing the reliability of thermistors, large changes in the resistance value of the device, easy to break, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

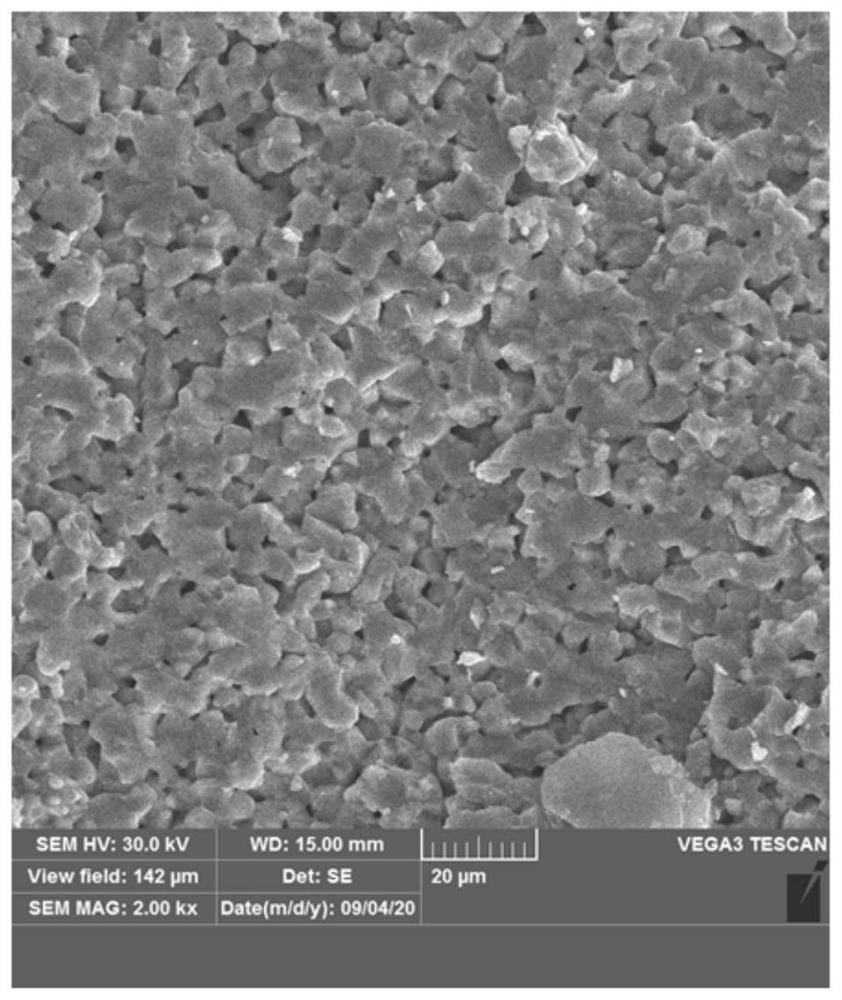

[0063]A high-reliability, low-resistance, high-B value NTC thermistor, the main component of its ceramic material includes: 50% Mn3O4, 40% Co3O4, 8% Fe2O3, 2% CuO, additives include: 1% SiO2, 0.5% ZrO2; The particle size of each oxide is 0.3μm-0.7μm.

[0064]A method for preparing a high-reliability, low-resistance, high-B value NTC thermistor includes the following steps:

[0065](1) Preparation of ceramic materials: weigh the oxides of the above ceramic materials and mix them by ball milling. The ball milling medium is zirconia balls and deionized water. The weight of the ceramic material: the weight of zirconia balls: the weight of deionized water = 1.1:2.5 :1.2 Perform ball milling and mixing, the ball milling time is 4h, and the ball milling speed is 260rpm for mixing. After drying, it is pre-fired at 900°C for 4 hours; then the ball mill is fine. The ball milling medium is deionized water and zirconia balls. The weight of the pre-fired powder: Zirconia ball weight: deionized water w...

Embodiment 2

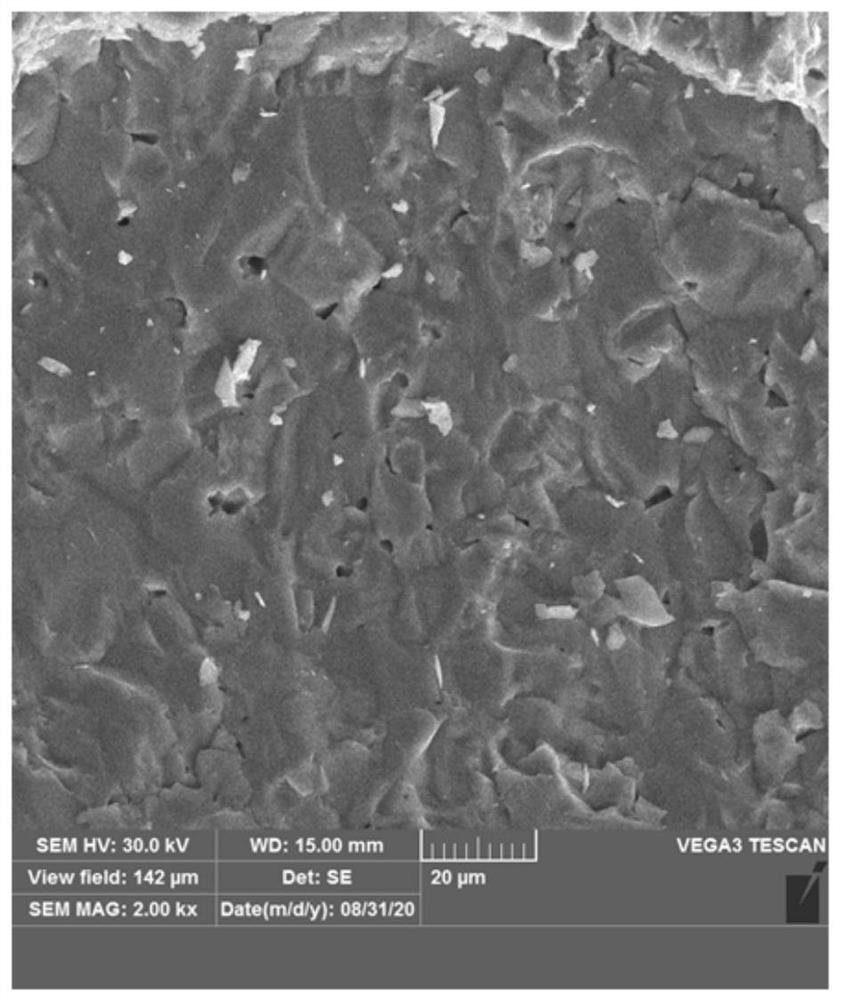

[0071]A high-reliability, low-resistance, high-B value NTC thermistor, the main component of its ceramic material includes: 50% Mn3O4, 40% Co3O4, 8% Fe2O3, 2% CuO, additives include: 1% SiO2, 0.5% ZrO2; Wherein the particle size of each oxide is 0.3μm-0.7μm.

[0072]A method for preparing a high-reliability, low-resistance, high-B value NTC thermistor includes the following steps:

[0073](1) Preparation of ceramic materials: weigh the oxides of the above ceramic materials and mix them by ball milling. The ball milling medium is zirconia balls and deionized water. The weight of the ceramic material: the weight of zirconia balls: the weight of deionized water = 1.1:2.5 :1.2 Perform ball milling and mixing, the ball milling time is 4h, and the ball milling speed is 260rpm for mixing. After drying, it is pre-fired at 900°C for 4 hours; then the ball mill is fine. The ball milling medium is deionized water and zirconia balls. The weight of the pre-fired powder: Zirconia ball weight: deionized...

Embodiment 3

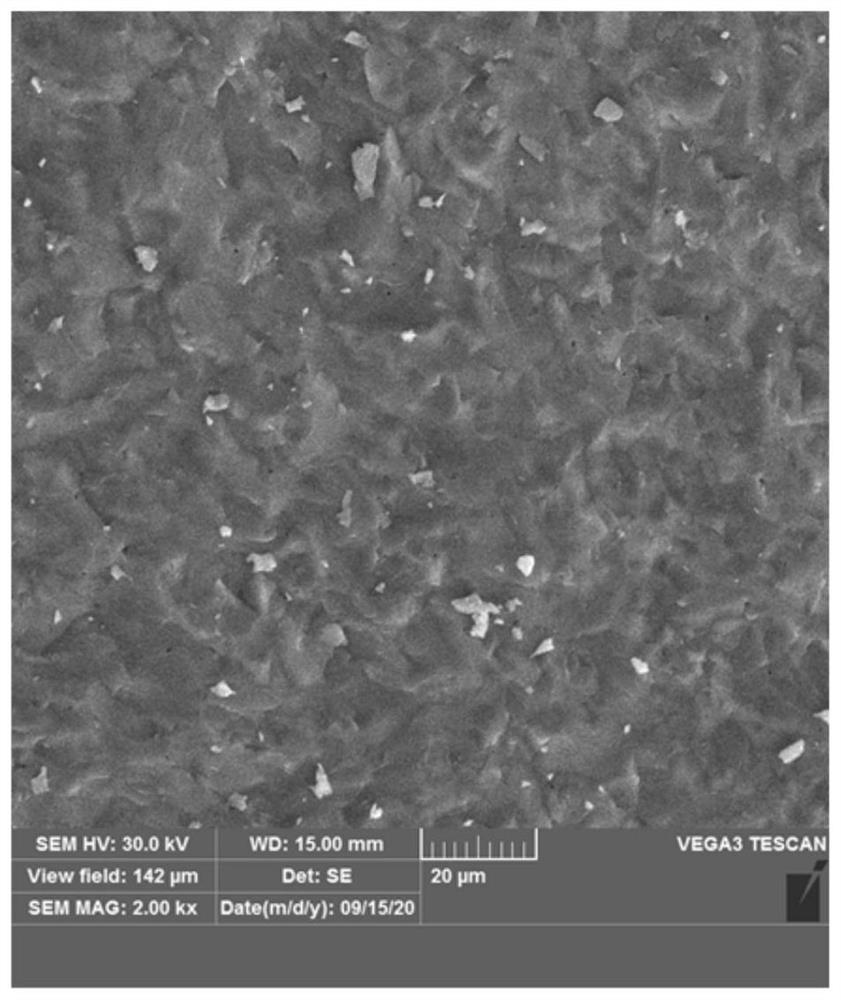

[0079]A high-reliability, low-resistance, high-B value NTC thermistor, the main component of its ceramic material includes: 50% Mn3O4, 40% Co3O4, 8% Fe2O3, 2% CuO, additives include: 1% SiO2, 0.5% ZrO2; Wherein the particle size of each oxide is 0.3μm-0.7μm.

[0080]A method for preparing a high-reliability, low-resistance, high-B value NTC thermistor includes the following steps:

[0081](1) Preparation of ceramic materials: weigh the oxides of the above ceramic materials and mix them by ball milling. The ball milling medium is zirconia balls and deionized water. The weight of the ceramic material: the weight of zirconia balls: the weight of deionized water = 1.1:2.5 :1.2 Perform ball milling and mixing, the ball milling time is 4h, and the ball milling speed is 260rpm for mixing. After drying, it is pre-fired at 900°C for 4 hours; then the ball mill is fine. The ball milling medium is deionized water and zirconia balls. The weight of the pre-fired powder: Zirconia ball weight: deionized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com