A preparation method of sic-hf(ta)c composite coating, composite coating and graphite base

A composite coating and graphite technology, applied in the coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of good compactness of the composite coating, long-term use of the graphite base, etc., and achieve good high temperature resistance , good compactness, enhance the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

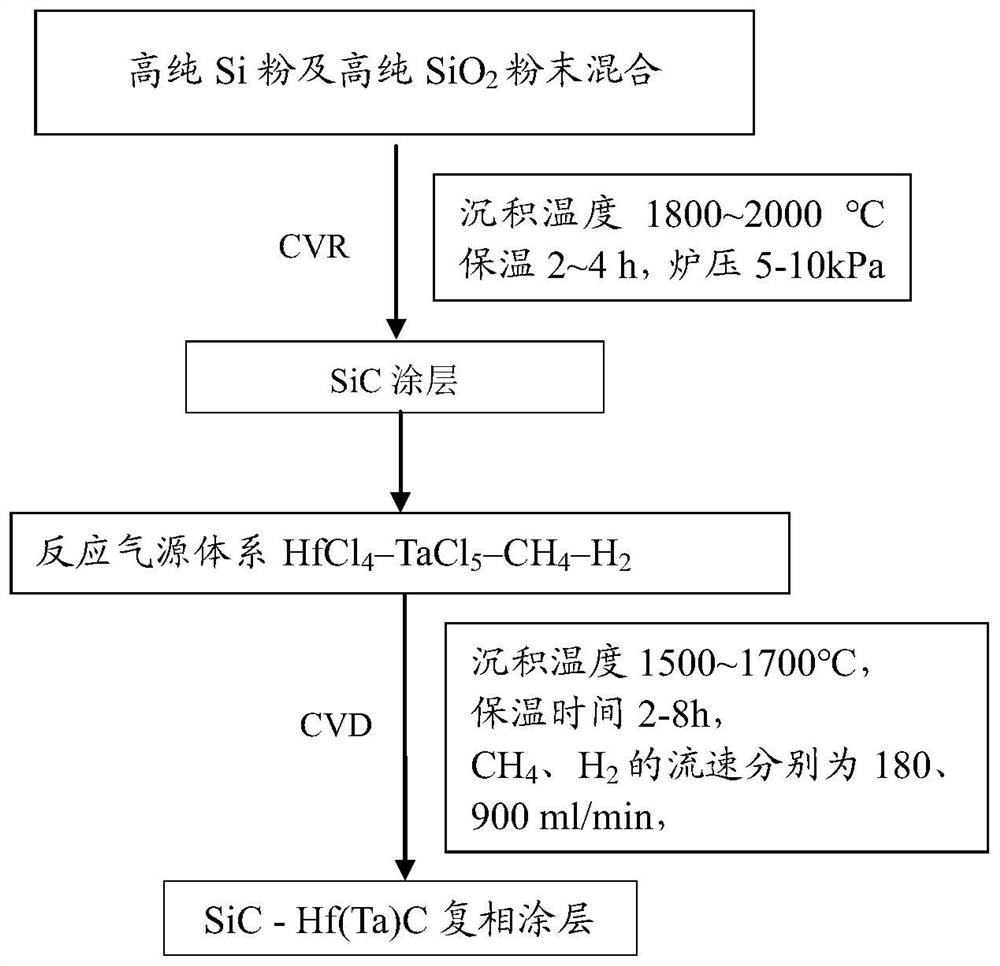

[0033] Such as figure 1 Shown, the preparation method of SiC-Hf(Ta)C composite coating provided by the present invention may further comprise the steps:

[0034] S1. Graphite substrate pretreatment: first, polish the graphite substrate with sandpaper, put it in alcohol, ultrasonically clean it for 40 minutes, then vacuum dry it at 100°C for 100 minutes, and place it on the graphite diverter plate;

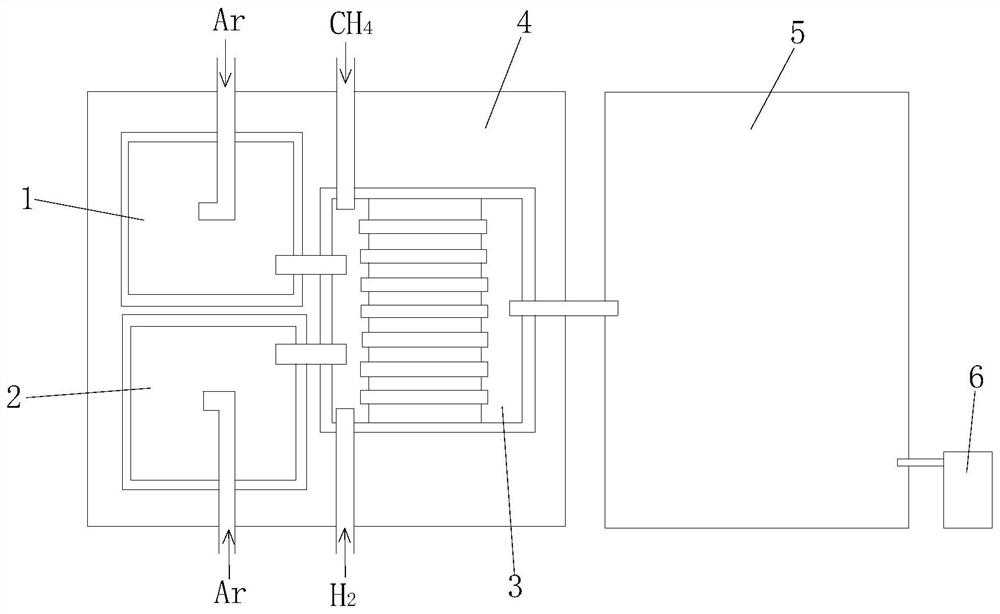

[0035] S2, high-purity Si powder and high-purity SiO 2 The powders were mixed in a molar ratio of 1.06:1, placed at the bottom of a graphite crucible, and then the crucible was placed in a deposition furnace; an appropriate amount of tantalum pentachloride powder and hafnium tetrachloride powder were placed in a tantalum pentachloride evaporation tank and a tetrachloride evaporator, respectively. Standby in the hafnium chloride evaporation tank; open the vacuum device to vacuumize the vapor deposition furnace equipment, and then feed argon to make the equipment full of argon;

[00...

Embodiment 2

[0045] The preparation method of SiC-Hf(Ta)C composite coating provided by the present invention comprises the following steps:

[0046] S1. Graphite substrate pretreatment: first, polish the graphite substrate with sandpaper, put it in alcohol, ultrasonically clean it for 40 minutes, then vacuum dry it at 100°C for 100 minutes, and place it on the graphite diverter plate;

[0047] S2, high-purity Si powder and high-purity SiO 2 The powders are mixed at a molar ratio of 1.10:1, placed at the bottom of a graphite crucible, and then the crucible is placed in a deposition furnace; appropriate amounts of tantalum pentachloride powder and hafnium tetrachloride powder are placed in a tantalum pentachloride evaporation tank and a tetrachloride evaporator, respectively. Standby in the hafnium chloride evaporation tank; open the vacuum device to vacuumize the vapor deposition furnace equipment, and then feed argon to make the equipment full of argon;

[0048] S3. Raise the temperature...

Embodiment 3

[0052] The preparation method of SiC-Hf(Ta)C composite coating provided by the present invention comprises the following steps:

[0053] S1. Graphite substrate pretreatment: first, polish the graphite substrate with sandpaper, put it in alcohol, ultrasonically clean it for 40 minutes, then vacuum dry it at 100°C for 100 minutes, and place it on the graphite diverter plate;

[0054] S2, high-purity Si powder and high-purity SiO 2 The powders are mixed at a molar ratio of 1.05:1, placed at the bottom of a graphite crucible, and then the crucible is placed in a deposition furnace; appropriate amounts of tantalum pentachloride powder and hafnium tetrachloride powder are placed in a tantalum pentachloride evaporation tank and a tetrachloride evaporator, respectively. Standby in the hafnium chloride evaporation tank; open the vacuum device to vacuumize the vapor deposition furnace equipment, and then feed argon to make the equipment full of argon;

[0055] S3. Raise the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap