Prefabricated wallboard and assembly type connecting structure of prefabricated wallboard and building main body

A technology for prefabricating wall panels and building bodies, which is applied to building components, building structures, buildings, etc., can solve the problems of inconvenient connection between wall panels and building bodies, and achieve the advantages of inconvenient connection, simple structure of connecting components, and reduced quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

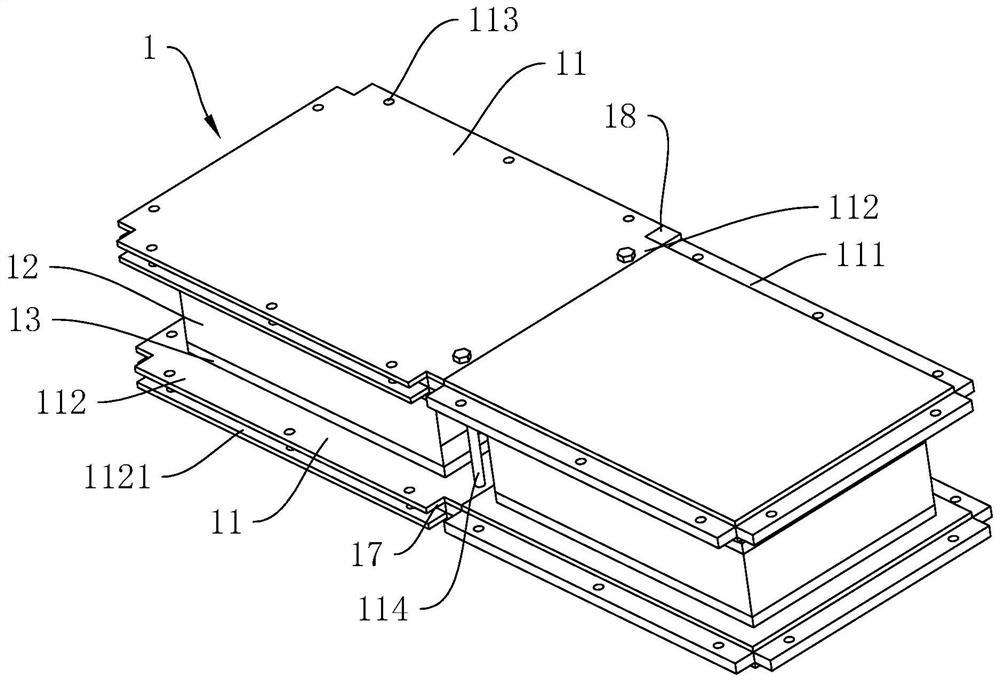

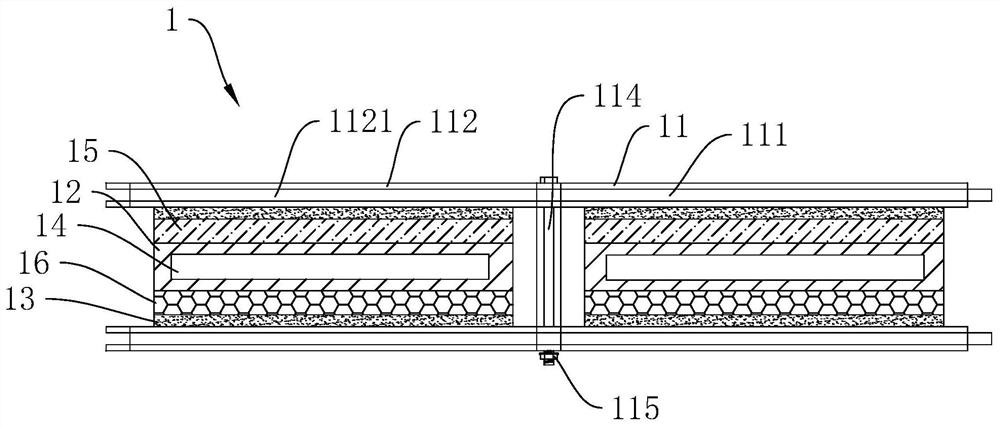

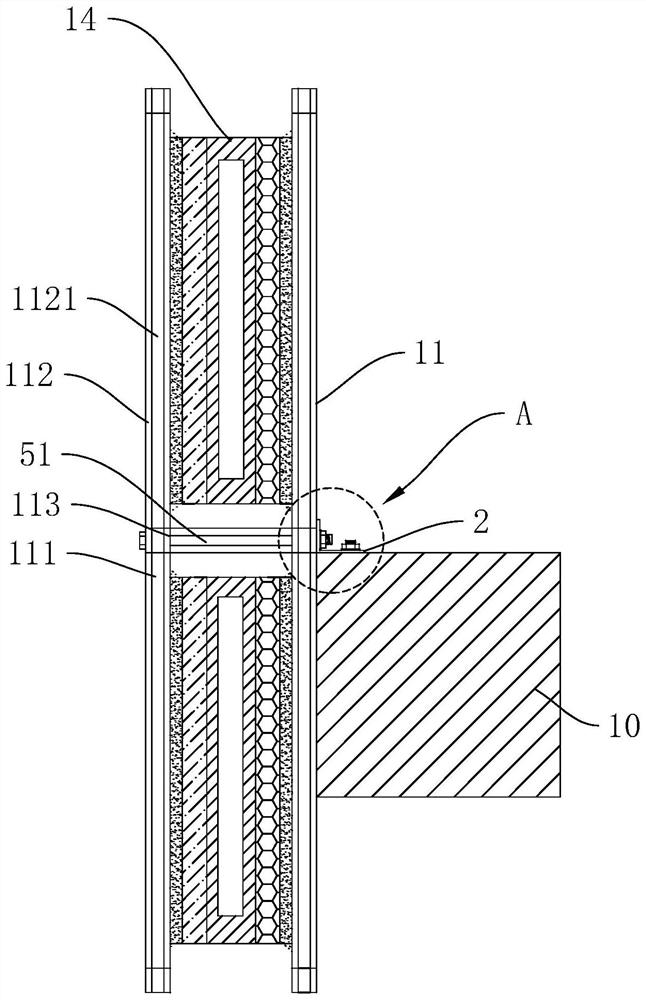

[0040] The following is attached Figure 1-7 The application is described in further detail.

[0041] The embodiment of the application discloses a prefabricated wall panel.

[0042] refer to figure 1 and figure 2 , the prefabricated wall panel includes a wall panel body 1, the wall panel body 1 includes two oppositely arranged exterior wall panels 11, a partition 12 is arranged between the two exterior wall panels 11, and a relief is arranged between the partition 12 and the exterior wall panels 11. The shock layer 13 and the partition board 12 are provided with a vacuum tank 14 , and the partition board 12 is provided with a heat insulation layer 15 and a sound insulation layer 16 on both sides of the vacuum tank 14 .

[0043] Among them, the shock-absorbing layer 13 is made of rubber shock-absorbing plate, which has high compressibility while providing shock-absorbing effect, and can improve the tightness of the connection between the adjacent wallboard bodies 1; the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com