Novel wind power generation device and assembly and power generation method

A wind power generation device and a new type of technology, which are applied in wind turbine combinations, electromechanical devices, wind energy power generation, etc., can solve the problems of inconvenient installation and debugging, high equipment cost, and low power generation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

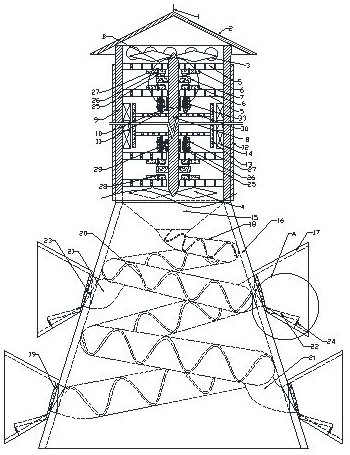

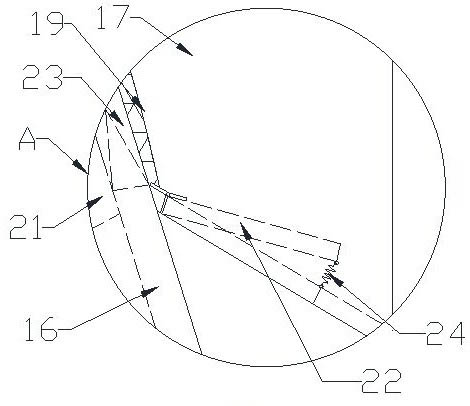

[0059] like figure 1 and Figure 5 As shown, a new type of wind power generation device includes a generator tube 9 and an induced draft tube 16 located below the generator tube, and the generator tube 9 communicates with the induced draft tube 16 . The air-inducing tube 16 has a small upper part and a lower part in a conical shape, and several air-intake tubes 17 are arranged on the outer wall of the air-inducing tube 16 . Preferably, several described air inlet tubes 17 are divided into several layers from top to bottom along the air induction tube 16, and the quantity of each layer of air inlet tubes is several, and the air inlet tubes are evenly distributed along the circumference of the air induction tube 16. Layout, and respectively set in four orientations of east, south, west and north ( figure 1 In order to show the details of the air duct more clearly, the air inlet tubes on the front and rear sides outside the air duct are omitted). In order to prevent wind from ...

Embodiment 2

[0085] The difference between this embodiment and embodiment one is:

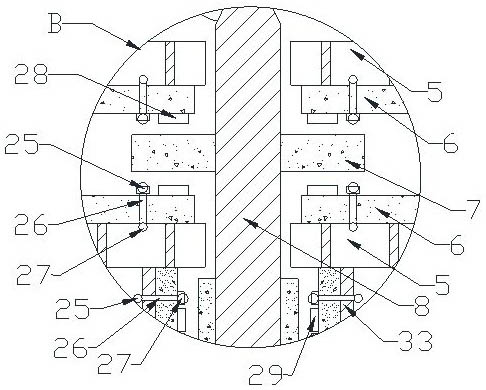

[0086] like Figure 5As shown, the first buffer mechanism includes several first rollers 31 that are annularly arranged on the axially fixed magnet 6, opposite to the first fixed magnet ring 7, and the rolling direction of each first roller 31 on the upper and lower sides is the same as that of the first roller 31. A fixed magnet ring 7 rotates in the same direction, and the first roller 31 is suspended, and neither the top nor the bottom of the first roller 31 is in contact with the axial fixed magnet 6 . The connecting column 39 of the first roller 31 passes through the fixed magnet 6 in the axial direction and is connected with a fixing anti-off piece 40 .

[0087] The second buffer mechanism includes several second rollers 32 that are annularly arranged on the radially fixed magnet 10, opposite to the second fixed magnet ring 11, and the rolling direction of the second roller 32 arranged in the circumf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com