Water inlet structure of upward flow filter tank

A water inlet and filter technology, which is applied in the field of water treatment, can solve problems such as the inability to fold down the drainage main canal, the difficulty in setting up water inlet and overflow measures, and the restriction of the elevation layout of the filter tank, so as to save land and construction costs and avoid valves. Installation and maintenance are difficult and the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

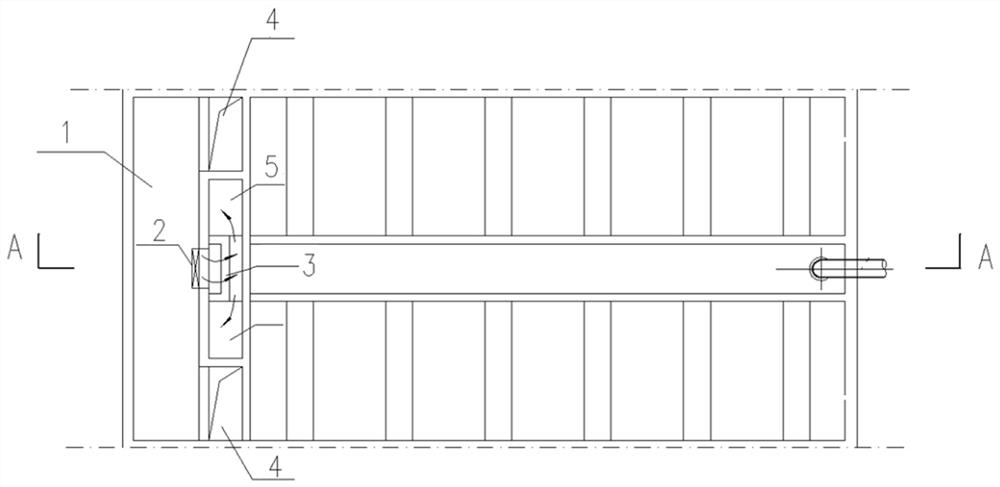

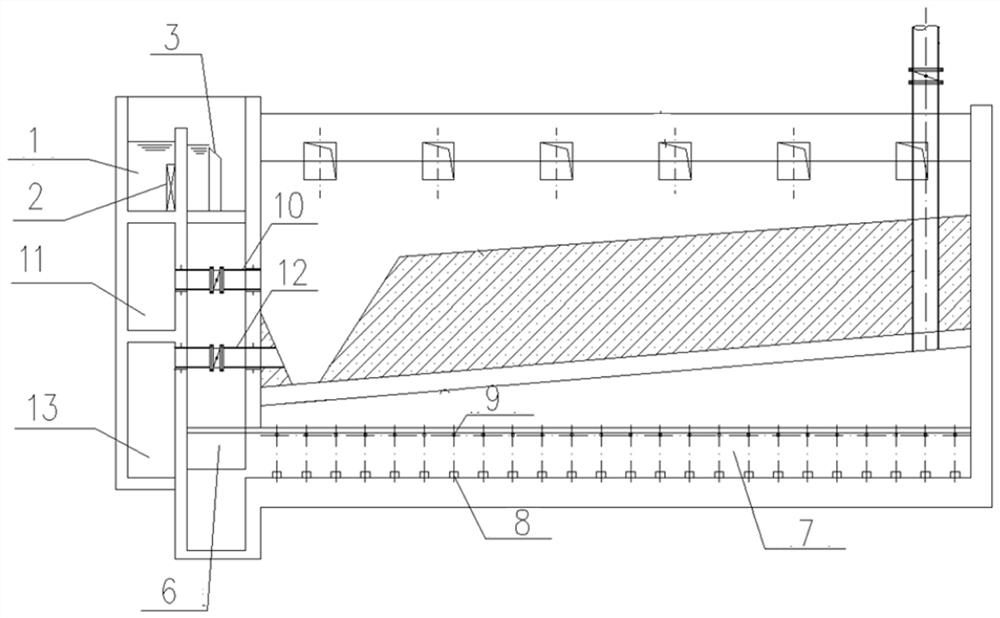

Embodiment 1

[0017] The upflow carbon filter with a central channel adopts this water intake method, including the main water intake channel 1, the single filter tank inlet valve 2, the water inlet weir 3 and the vertical shaft 5, and a double-layer central channel is set in the middle of the filter tank. The upper layer of the canal is equipped with water production and drainage channels, and the lower layer is equipped with water distribution and gas distribution channels. It is characterized in that the single-cell filter inlet valve 2 is arranged in front of the water inlet weir 3; On both sides of the gas channel, the inner side wall of the shaft 5 (that is, the side wall of the vertical shaft 5 on the side of the central water distribution channel facing the middle side, that is, the side wall facing the vertical shaft on the other side) continues to extend downward from the bottom plate of the vertical shaft to below The lower edge of the air distribution hole 9 of the water and gas ...

Embodiment 2

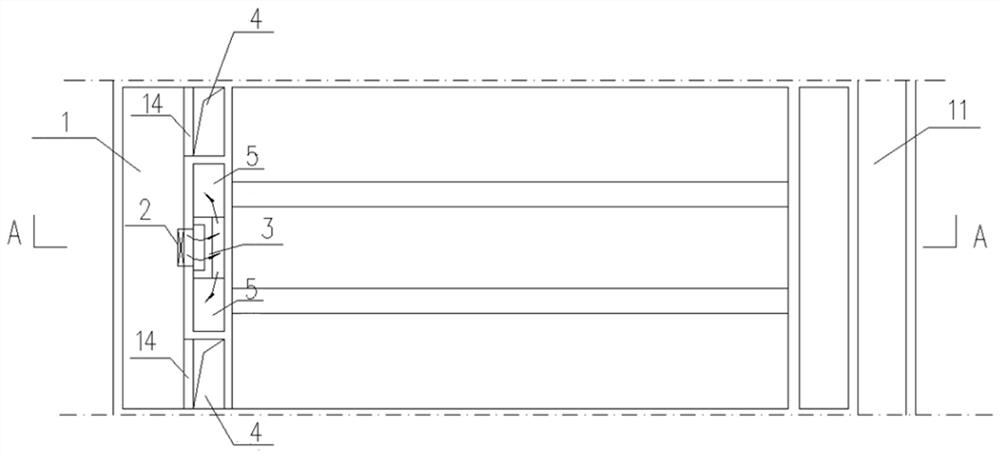

[0022] The upflow carbon filter without a central channel adopts the water inlet method, including the main water inlet channel 1, the single-cell filter water inlet valve 2, the water inlet weir 3 and the vertical shaft 5, and the characteristic is that the single-cell filter tank The valve 2 is arranged in front of the water inlet weir 3; the vertical shaft 5 is connected up and down, and the bottom plate of the well is deep, and a water seal baffle 6 is set at the connection between the vertical shaft 5 and the bottom water distribution channel 7. As shown in the figure, the inner side wall of the vertical shaft 5 extends downwards to 50-200mm lower than the lower edge of the air distribution hole 9 of the water distribution and air distribution channel to form a water seal baffle 6, and the remaining side walls are connected to the bottom plate of the vertical shaft. An overflow well 4 is arranged outside the vertical shaft 5, and an overflow weir 14 is arranged between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com