Solar panel metal frame wire drawing process machining device

A metal frame and process processing technology, which is applied in the field of solar panel metal frame wire drawing process processing devices, can solve the problems of large use limitations, cumbersome processing methods, and low work efficiency, so as to improve reliability, practicability and reliability , Convenient and accurate control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

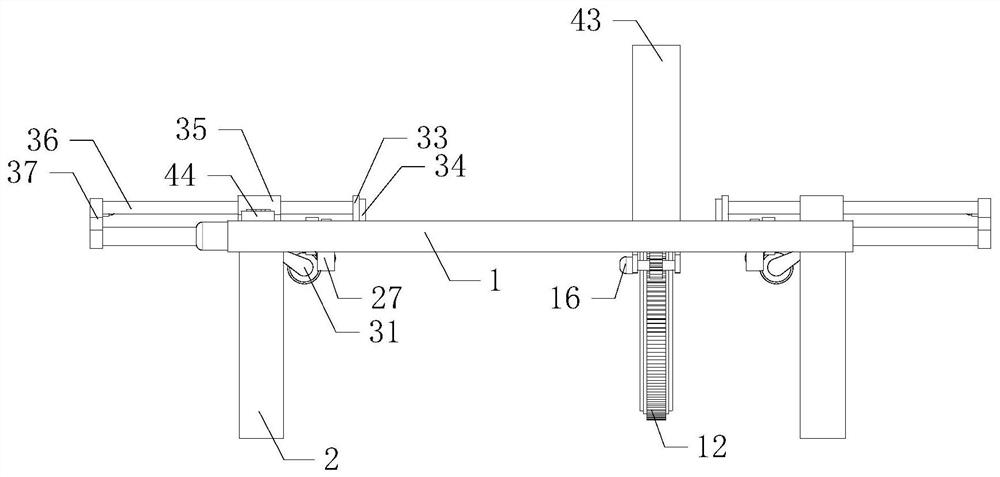

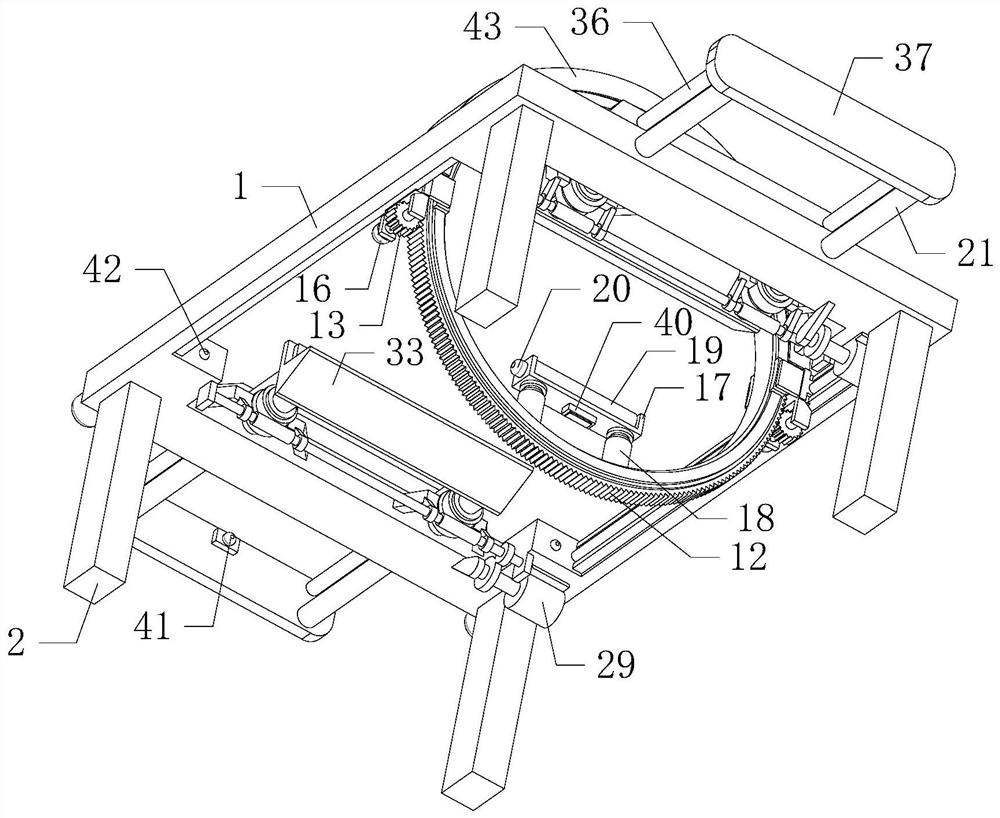

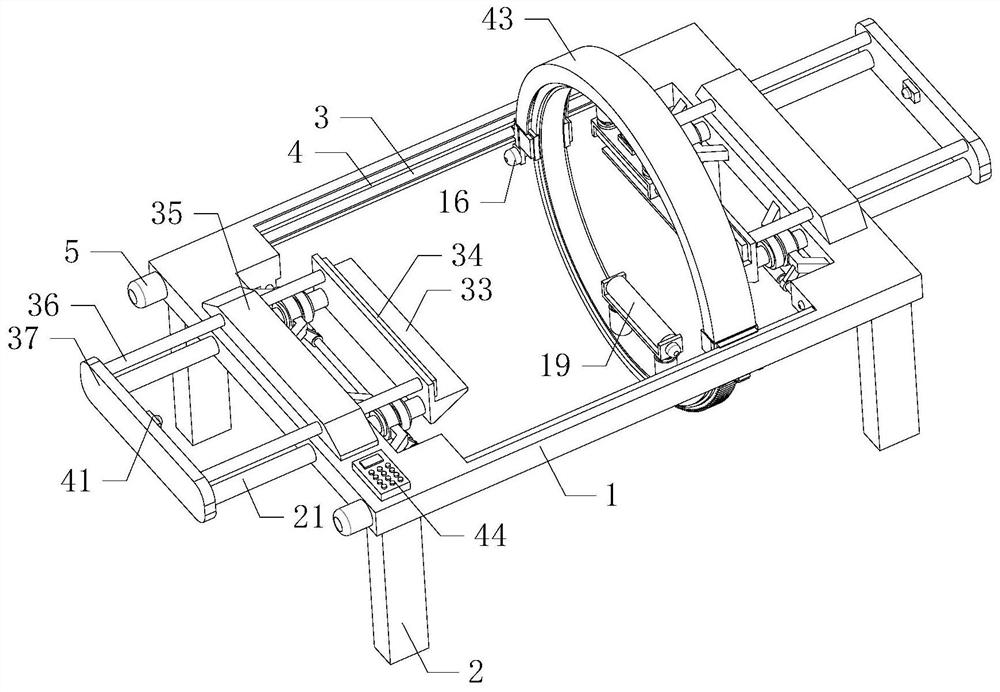

[0022] Such as Figure 1 to Figure 7 As shown, a solar panel metal frame wire drawing process processing device of the present invention, when it is working, the metal frame to be wire-drawn is placed on two sets of fixing devices, and the central control box 44 controls the two sets of fixing devices to carry out the process on the metal frame. Fixed, the central control box 44 controls to open two groups of second motors 16, two groups of second motors 16 rotate synchronously, two groups of second motors 16 drive two groups of first gears 13 to rotate through two groups of first rotating shafts 14 respectively, One gear 13 is meshed with the outer gear ring 12, the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com