Production system for composite pipe and process thereof

A technology for composite pipes and production systems, applied in applications, household appliances, tubular objects, etc., can solve problems such as low processing efficiency, achieve the effect of improving product quality and improving installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The following is attached Figure 1-21 The application is described in further detail.

[0059] The composite pipe is a hollow pipe. The composite pipe includes a first plastic film layer, a steel wire skeleton, a second plastic film layer and a protective film layer. The outer direction is set in sequence, and the steel wire skeleton may be replaced with glass fiber wire according to the actual product.

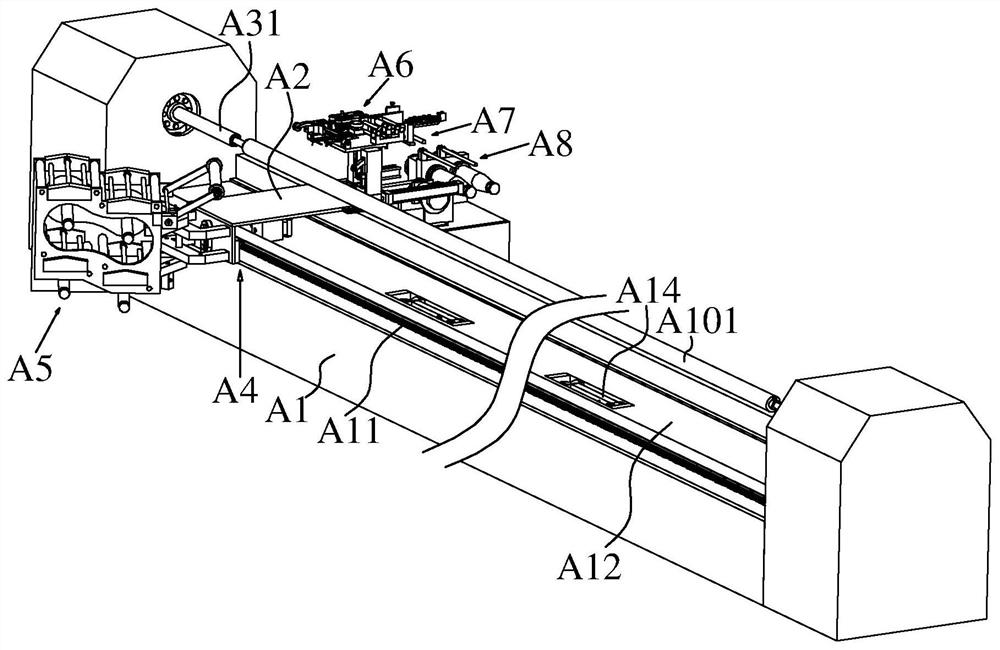

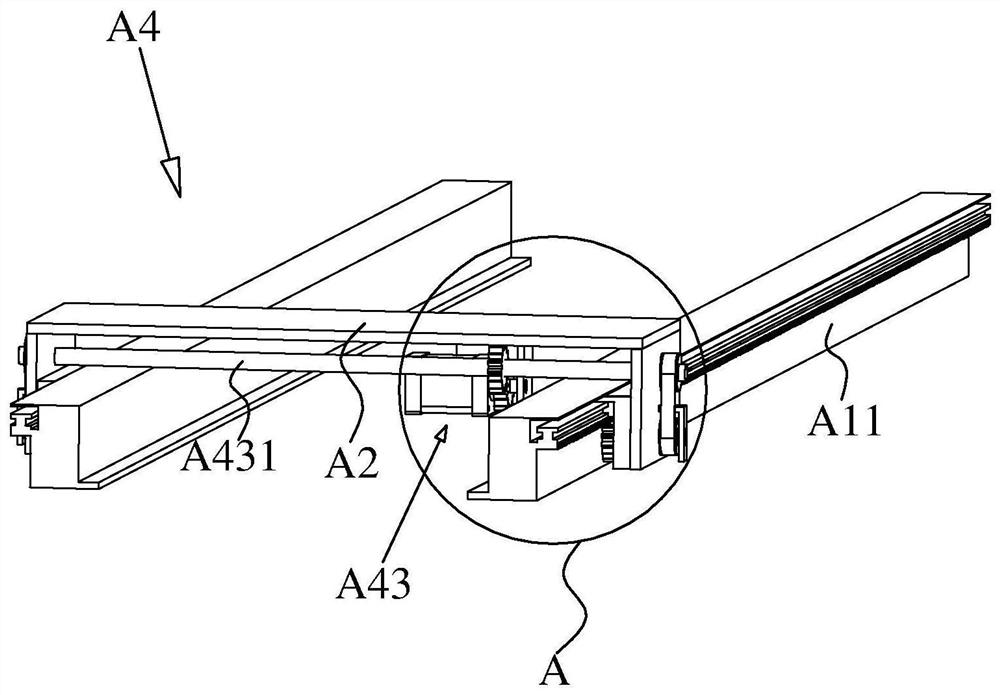

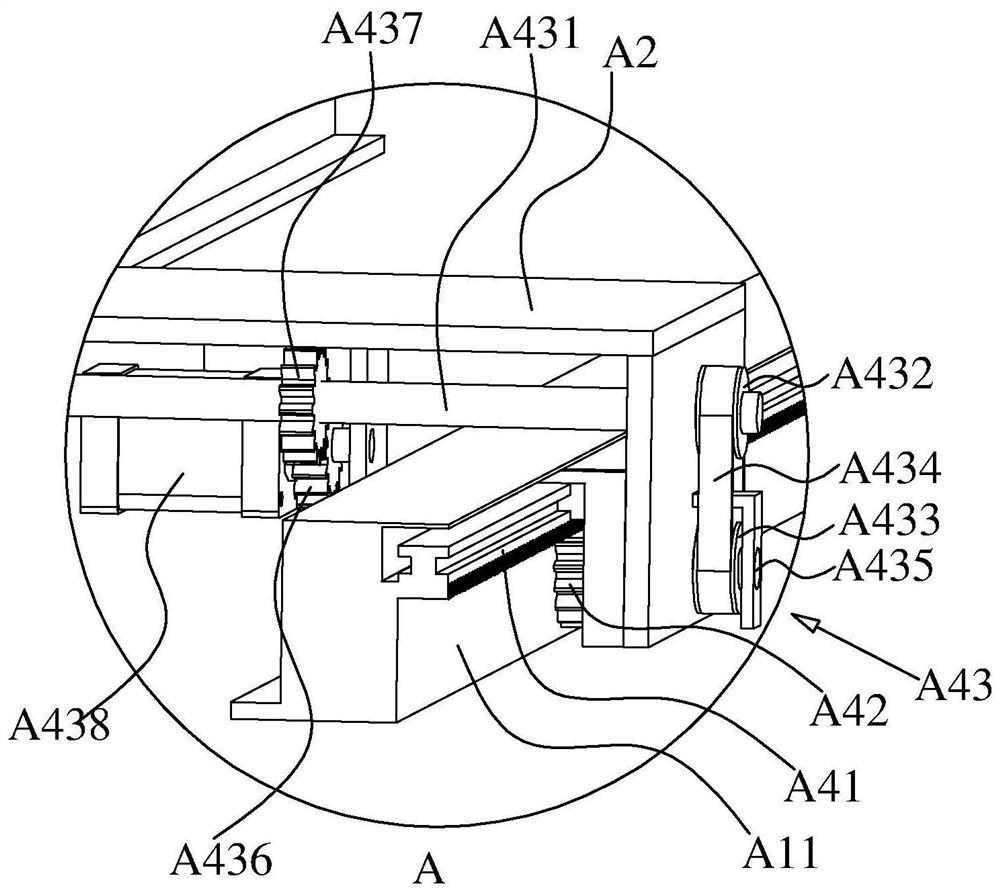

[0060] The embodiment of the present application discloses a production system for composite pipes. refer to figure 1 , the production system includes a winding device, the winding device includes a first frame A1 and a conveying table A2, the first frame A1 extends horizontally, the top of the first frame A1 is provided with a first accommodating groove A12, and the first accommodating groove A12 Extending toward the length direction of the first frame A1, the first frame A1 is provided with slide rails A11 on opposite sides of the bottom of the first receiving gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com