Elastic interlayer assembly

A component and interlayer technology, applied in the field of interlayer components, can solve the problems of lack of sturdiness and damage, and achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Identical or similar components in different figures are provided with the same reference signs. The descriptions in the figures are schematic.

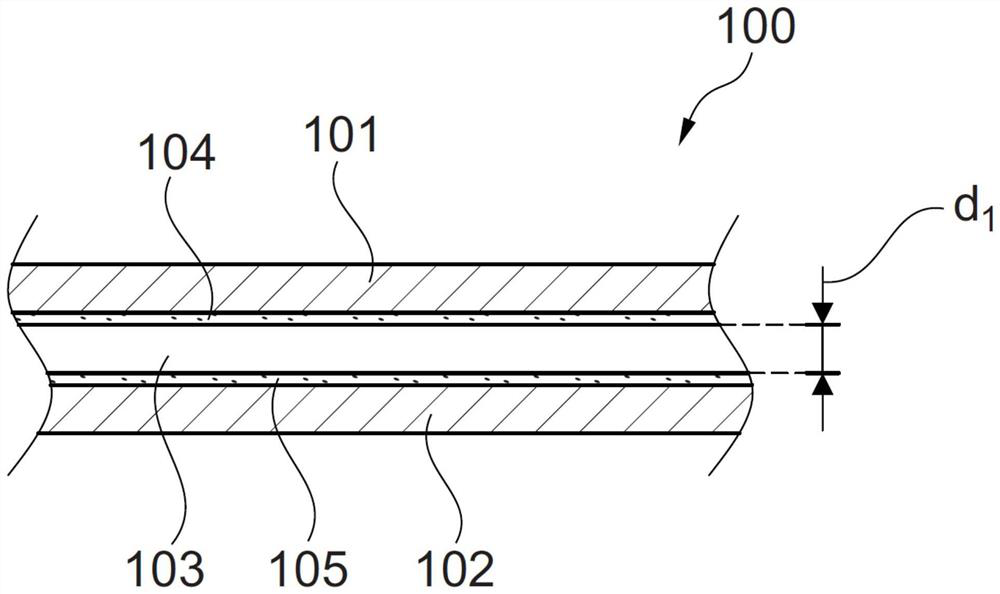

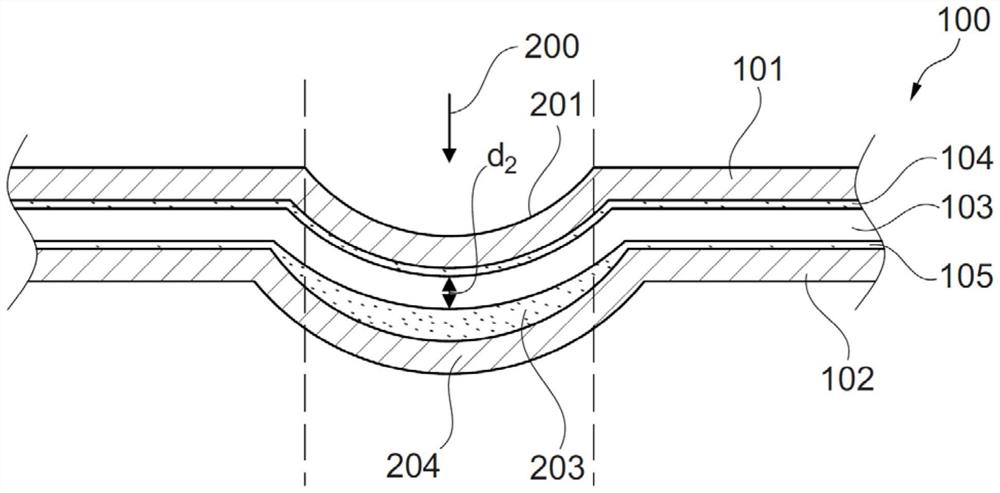

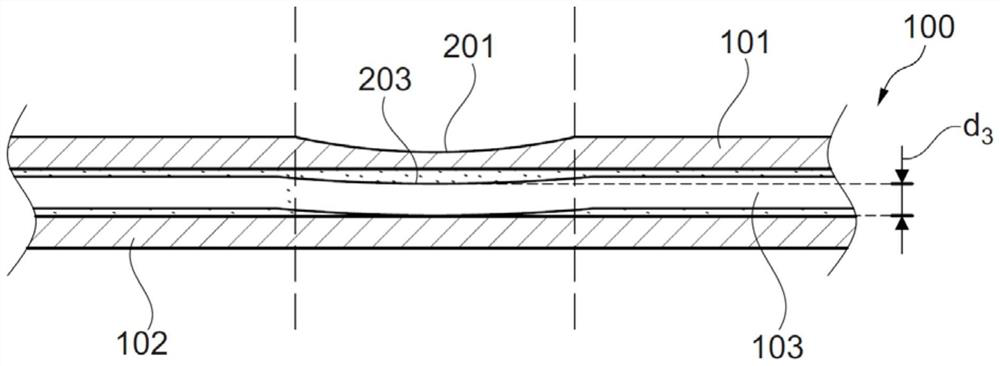

[0044] figure 1 A schematic diagram of a sandwich assembly 100 according to the invention is shown. The sandwich assembly 100 has a first cover layer 101 , a second cover layer 102 and a core layer 103 . The core layer 103 is arranged between the first cover layer 101 and the second cover layer 102 such that the first cover layer 101 , the core layer 103 and the second cover layer 102 form a sandwich structure. The core layer 103 has a shear stiffness greater than 5 MPa. The core layer 103 is configured to be recoverable such that when the thickness of the core layer 103 is reduced by 20% of the original thickness d1 due to the compressive force, at least 95% of the original thickness of the core layer 103 is recoverable.

[0045] For example, the core layer 103 is configured to be more elastic than at least the first cov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com