ZWY type mining crawler excavation type loader mud scraping and cleaning device

A cleaning device and loader technology, which is applied to tracked vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of low efficiency and manpower consumption, and achieve the effect of thorough removal, guaranteed scraping effect, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

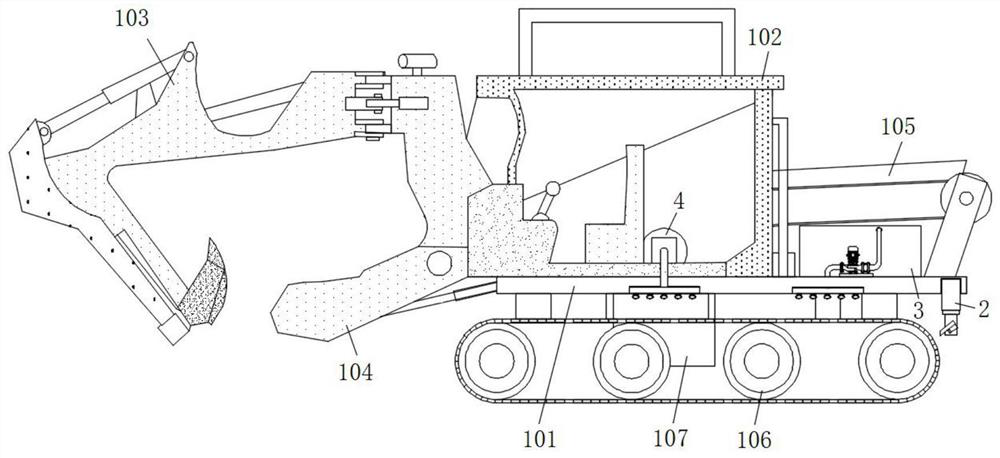

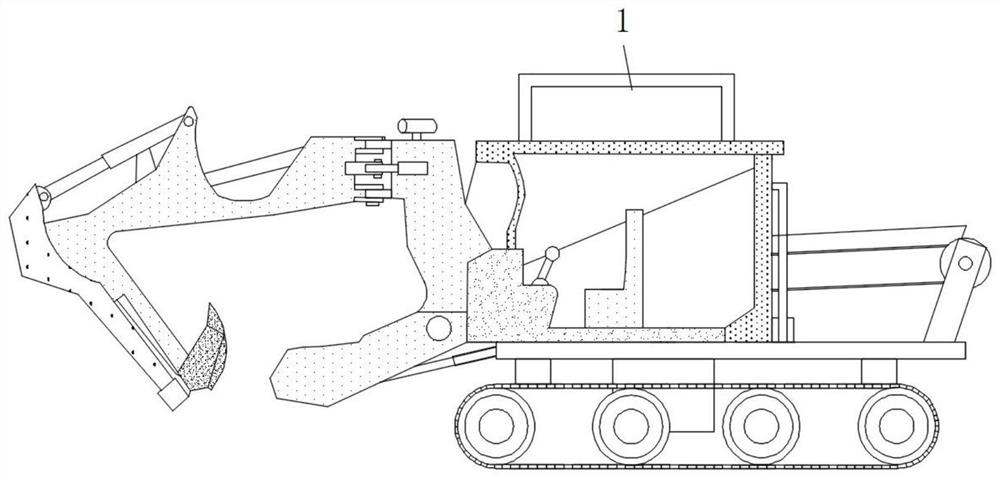

[0033] refer to Figure 1-6, a ZWY type mining crawler excavator loader mud scraping and cleaning device, including an excavator body 1, the excavator body 1 includes a bottom plate 101, a cab 102 is fixed in the middle of the top surface of the bottom plate 101, and a front end upper side of the bottom plate 101 is installed Excavating mechanism 103, conveying mechanism 1 104 is installed on the front end lower side of base plate 101, conveying mechanism 2 105 is installed on the rear side of base plate 101 top surface, drive crawler belt 106 is installed on the front and rear sides of the lower end of base plate 101, also is fixed in the middle part of base plate 101 lower end face. The chassis 107, the bottom surface of the bottom plate 101 is away from the excavation mechanism 103 and is provided with a mud scraping mechanism 2. The mud scraping mechanism 2 includes an electric telescopic rod-201, and the output ends of the two electric telescopic rods-201 in the same group...

Embodiment 2

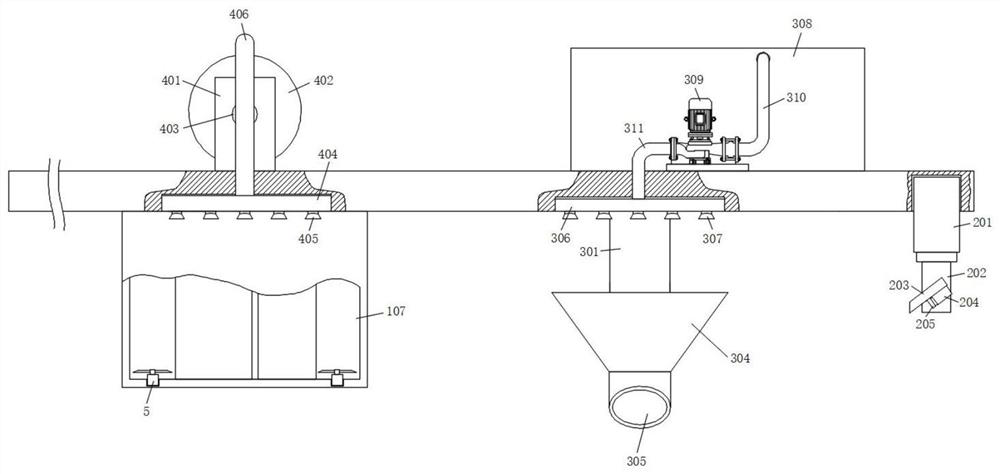

[0036] Such as image 3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the inner bottom surface of the chassis 107 is provided with through holes and is fixed with exhaust fans 5 , and multiple exhaust fans 5 are provided and evenly distributed on the inner bottom surface of the chassis 107 .

[0037] In this embodiment, a plurality of exhaust fans 5 are installed on the inner bottom surface of the chassis 107, so that the heat dissipated by the driving parts in the chassis 107 can be quickly discharged, and the air-drying quality of the driving track 106 is well guaranteed.

Embodiment 3

[0039] Such as image 3 and 4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, four electric telescopic rods 201 are provided and distributed symmetrically in two groups on the front and rear sides of the bottom plate 101, and the electric telescopic rods one 201 are all fixed on the bottom plate by screws. 101 inside position.

[0040] The distance between the front and rear ends of the mud removal plate 205 is consistent with the distance between the front and rear ends of the scraper 203 .

[0041] In this embodiment, the distance between the front and rear ends of the mud removal plate 205 is consistent with the distance between the front and rear ends of the scraper 203 , so that the mud removal board 205 can completely remove the soil on the surface of the scraper 203 under the action of the electric telescopic rod 2 204 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com