Graphite puffing device high in heating speed and uniform in heating

A technology of heating speed and puffing device, applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of slow heating speed, slow production efficiency, pollution of the environment, etc., and achieve the effect of rapid heating and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

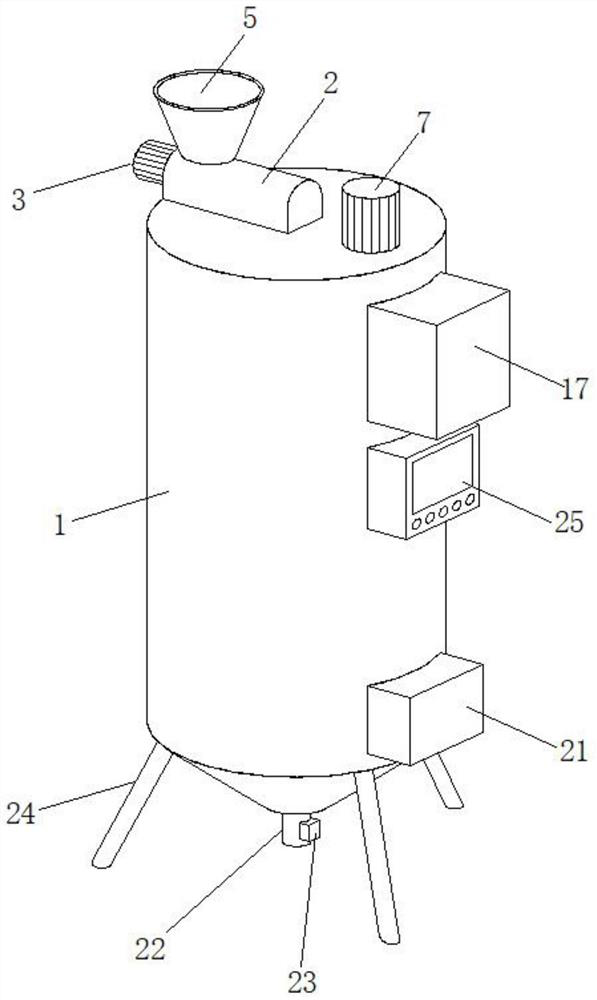

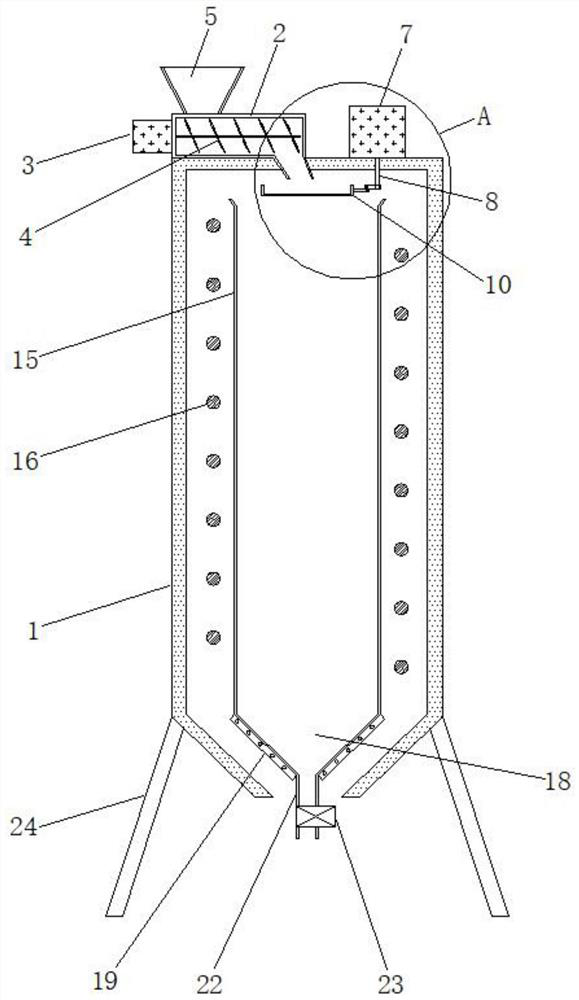

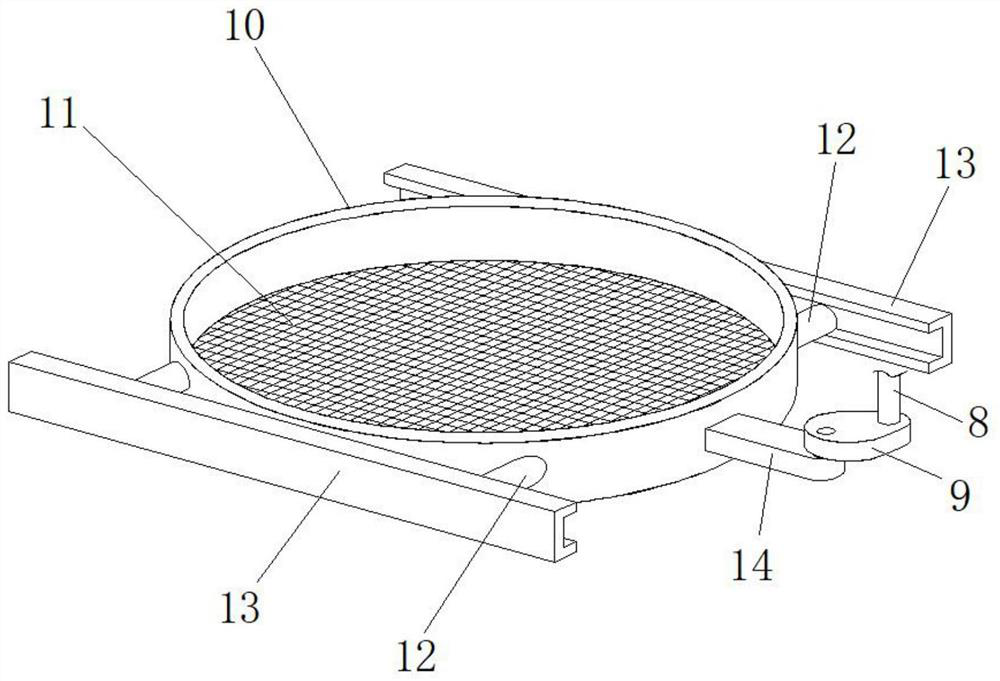

[0029]SeeFigure 1-5, A graphite puffing device with fast heating speed and uniform heating, comprising a cylindrical shell 1, a screw feeder 2 is fixedly installed on the top side of the cylindrical shell 1, and the outer side of the screw feeder 2 A first motor 3 is fixedly installed, and the first motor 3 is drivingly connected to a screw 4 arranged transversely in the screw feeder 2. A hopper 5 is provided at the top and outer end of the screw feeder 2. The bottom inner end of the feeder 2 is provided with a discharging pipe 6 extending into the inside of the cylindrical shell 1, and a second motor 7 is fixedly installed on the other side of the top of the cylindrical shell 1. The output shaft 8 is fixedly sleeved with an eccentric wheel 9 arranged in the cylindrical shell 1, a sieve tray 10 is arranged under the lowering pipe 6, and the bottom of the sieve tray 10 is fixedly installed with a screen 11, so Slide rods 12 are fixedly installed on both sides of the sieve tray 10, an...

Embodiment example 2

[0033]SeeFigure 6 Specifically, the thin-walled guide tube 15 is made of high-temperature resistant ceramic material, and the thickness of the thin-walled guide tube 15 is 3-5 mm; and the top of the thin-walled guide tube 15 is provided with a horn-shaped expansion that is inclined to the outside.口26. The thin-walled guide tube 15 made of high-temperature resistant ceramic material can play a role of heat insulation when the graphite is heated, and it can also prevent the falling graphite from spilling out of the thin-walled guide tube 15, and the insulated thin-walled guide tube 15 is placed in the induction The inside of the hollow copper tube coil 16 will not be heated, and the thinner thickness will not affect the inductive heating effect of the induction hollow copper tube coil 16; and the top of the thin-walled guide tube 15 is provided with a flared opening 26 inclined to the outside. It can prevent the graphite that has fallen from the sun from falling to the outside of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com