Chlorination furnace slurry return device and method

A technology of chlorination furnace and slurry return, applied in the direction of titanium tetrachloride, titanium halide, etc., can solve problems such as easy blockage, poor atomization effect, unstable negative pressure of chlorination furnace, etc., and achieve reduction of impurity content, fog Good chemical effect and fine particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

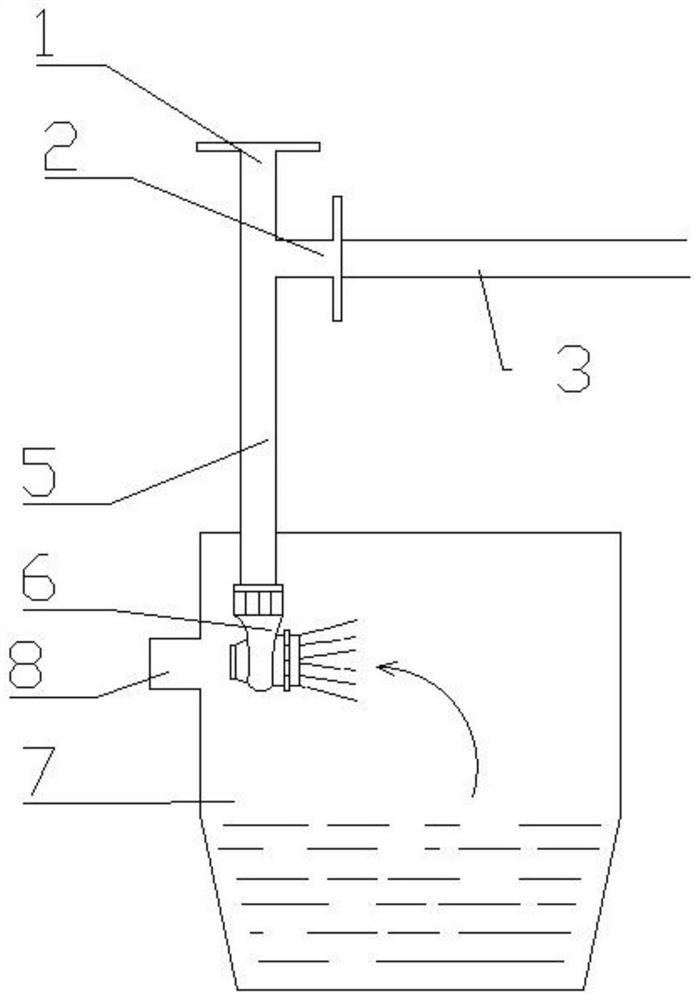

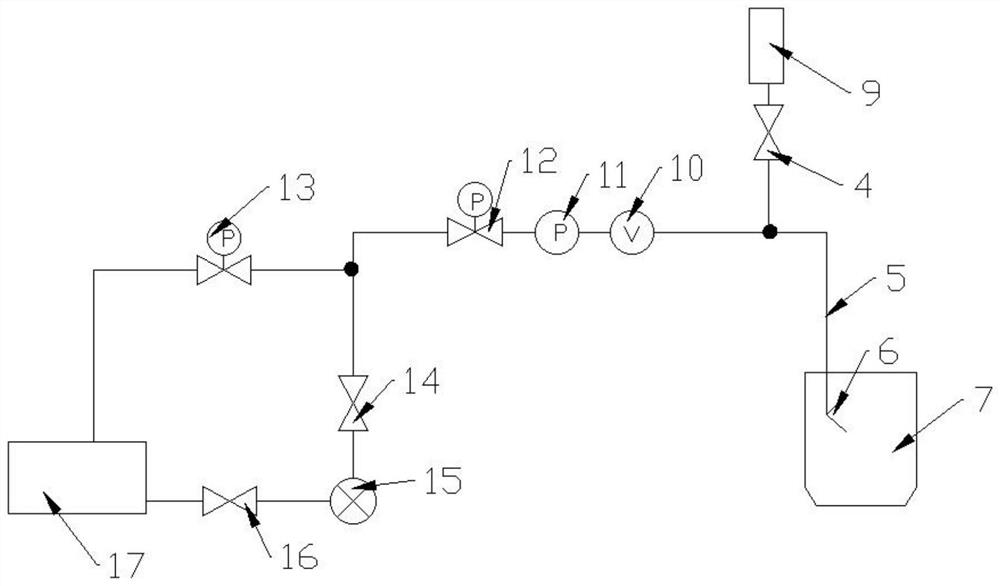

[0034] In this embodiment, the spray pipe 5 and the power wave nozzle 6 are welded together, the power wave nozzle 6 is located in the chlorination furnace 7, the chlorination furnace 7 is provided with a flue port 8, the material of the power wave nozzle 6 is 316 stainless steel, and the power wave nozzle 6 is made of 316 stainless steel. The nozzle of the wave nozzle 6 faces away from the flue mouth 8, the distance between the power wave nozzle 6 and the flue mouth 8 is 80cm, and the end of the spray pipe 5 away from the power wave nozzle 6 is provided with a dredging port 1, and the dredging hole 1 is a round hole. The pipe wall of the shower pipe 5 is provided with a feeding port 2, the feeding port 2 is connected with the feed pipe 3, the angle between the feed pipe 3 and the spray pipe 5 is 90°, and the pipe wall of the feed pipe 3 is connected with a A nitrogen pipeline, the nitrogen pipeline is connected with a third valve 4, and the third valve 4 is connected with a ni...

Embodiment 2

[0040] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0041] In this embodiment, the material of the power wave nozzle 6 is 321 stainless steel, the spray pipe 5 and the power wave nozzle 6 are screwed together, the distance between the power wave nozzle 6 and the flue mouth 8 is 70cm, and the feed pipe 3 The included angle with the spray pipe 5 is 45°.

Embodiment 3

[0043] In this embodiment, the power wave nozzle 6 is blocked, and the mud in the spray pipe 5 is accumulated. The pressure transmitter 11 detects that the pressure in the feed pipe 3 exceeds the normal range, and transmits the data to the control system. The control system controls the first valve. 16 is closed, and the first pneumatic valve 13 and the third valve 4 are controlled to open simultaneously, and the mud part flowing through the second valve 14 enters the return line, and flows back into the titanium tetrachloride tank 17 through the first pneumatic valve 13, while the nitrogen tank 9 release nitrogen, nitrogen enters the feed pipe 3 through the third valve 4, and purges the spray pipe 5 and the power wave nozzle 6, but due to too much mud accumulation, the power wave nozzle 6 fails to dredge, and the chlorination furnace returns to slurry The whole equipment of the device is powered off, waiting for maintenance personnel to dismantle and repair, and discharge the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com