Boiler flushing wastewater intelligent ash recycling system

A recovery system and boiler technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of large amount of wastewater, large cofferdam area, time spent on demolition and dredging long wait question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

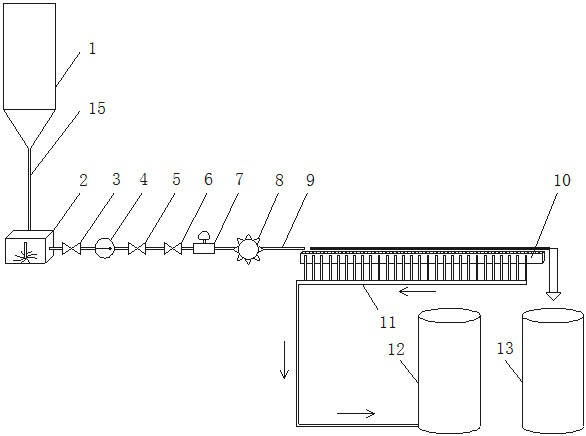

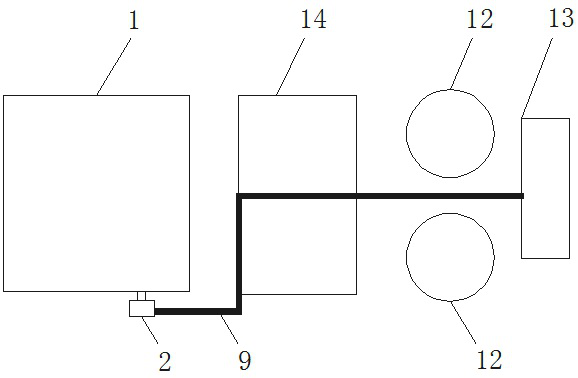

[0018] Such as Figure 1-2 As shown, an intelligent ash recovery system for boiler flushing wastewater, which includes a boiler 1, the bottom of the boiler 1 is connected to a sump 2 through a boiler flushing pipeline 15, and an agitator is arranged in the sump 2, and the sump The outlet end of the pool 2 is connected with a first shut-off valve 3 through a pipeline 9, the outlet end of the first shut-off valve 3 is connected with a sewage pump 4, and the outlet end of the sewage pump 4 is connected with a second shut-off valve 5. The outlet end of the second cut-off valve 5 is connected with a check valve 6, the outlet end of the check valve 6 is connected with a regulating valve 7, and the outlet end of the regulating valve 7 is connected with a swirl station 8, and the swirl station 8 The outlet end of the gypsum dehydrator is connected with a gypsum dehydrator 10, the upper part of the gypsum dehydrator 10 forms a gypsum channel, and the gypsum is collected in the gypsum t...

Embodiment 2

[0021] Such as Figure 1-2 As shown, an intelligent ash recovery system for boiler flushing wastewater, which includes a boiler 1, the bottom of the boiler 1 is connected to a sump 2 through a boiler flushing pipeline 15, and an agitator is arranged in the sump 2, and the sump The outlet end of the pool 2 is connected with a first shut-off valve 3 through a pipeline 9, the outlet end of the first shut-off valve 3 is connected with a sewage pump 4, and the outlet end of the sewage pump 4 is connected with a second shut-off valve 5. The outlet end of the second cut-off valve 5 is connected with a check valve 6, the outlet end of the check valve 6 is connected with a regulating valve 7, and the outlet end of the regulating valve 7 is connected with a swirl station 8, and the swirl station 8 The outlet end of the gypsum dehydrator is connected with a gypsum dehydrator 10, the upper part of the gypsum dehydrator 10 forms a gypsum channel, and the gypsum is collected in the gypsum t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com