Method for separating fair-faced concrete with different surfaces

A fair-faced concrete and clear-water technology, which is applied to the on-site preparation of building components, the connection of formwork/formwork/work frame, and construction, can solve problems such as separation of fair-faced concrete, reduce labor, reduce engineering costs, and demolition. The effect of the simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

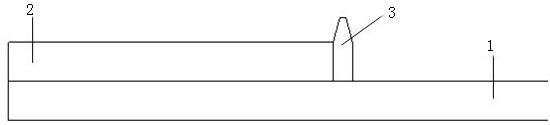

[0020] Such as figure 1 Shown: A separation method of fair-faced concrete with different surfaces, including the following steps:

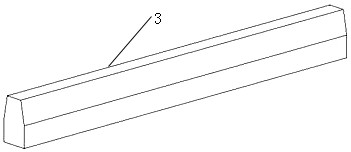

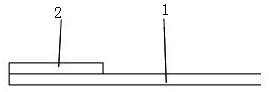

[0021] Such as figure 2 Shown: choose 4000mm*120mm*12mm for wood-grain clear water panel of the present invention, choose high-quality clear water liner for wood grain surface lining board 2440mm*1220mm*12mm, choose open seam strip 3 with size 25mm*15mm*10mm.

[0022] Step 1: Complete the design of fair-faced concrete formwork on different surfaces, and determine the parameters such as the size of various formwork.

[0023] Step 2: Process the lining 1 board to meet the detailed design requirements, and then install a smooth clear water formwork on the lining board. Smooth clear water panel 2 adopts high-quality clear water panel with the same thickness as wood grain clear water panel 4 (such as figure 2 shown).

[0024] Note: This step can be adjusted to other effect templates when there are other combinations other than the combination of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com