A kind of intelligent water source power shearer dust collector and dust removal method

A technology of coal shearer and dust collector, applied in the field of intelligent water source powered coal shearer dust collector and dust removal, can solve the problems that the fog field cannot effectively cover the dust source, the installation and maintenance of dust removal equipment is difficult, and the nozzle is difficult to ensure the spray effect, etc. Achieve the effect of protecting physical and mental health, reducing the incidence of pneumoconiosis, and inhibiting the escape of coal dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0042] Aiming at the problems existing in the prior art, the present invention provides a dust collector for an intelligent water-source power coal shearer. The present invention is described in detail below with reference to the accompanying drawings.

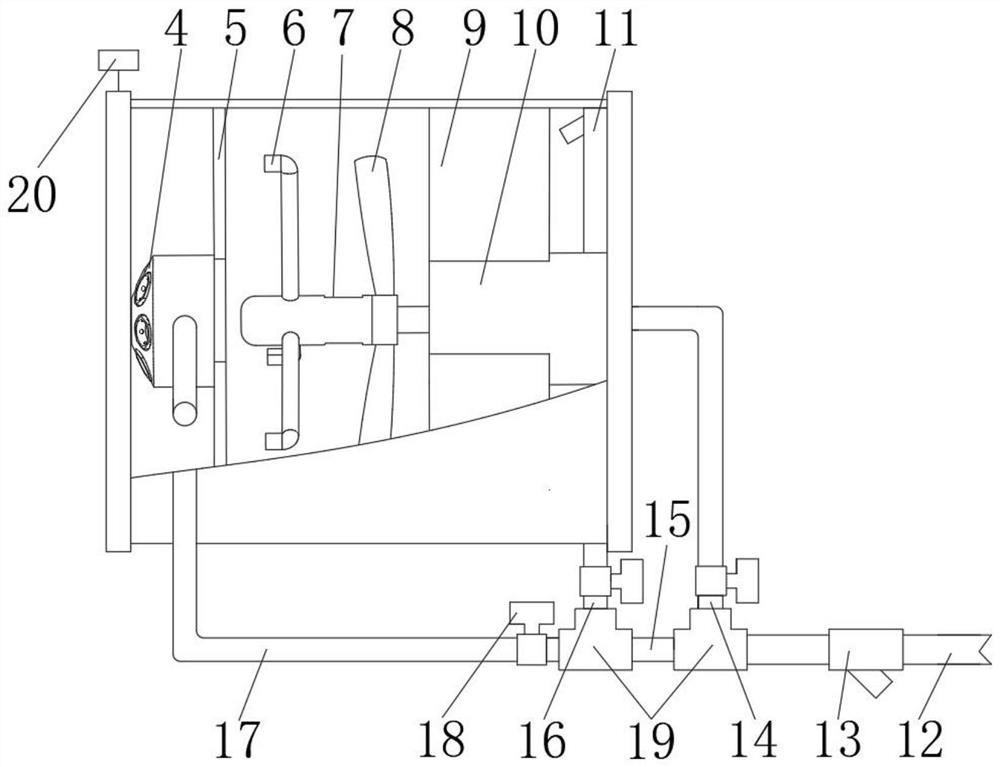

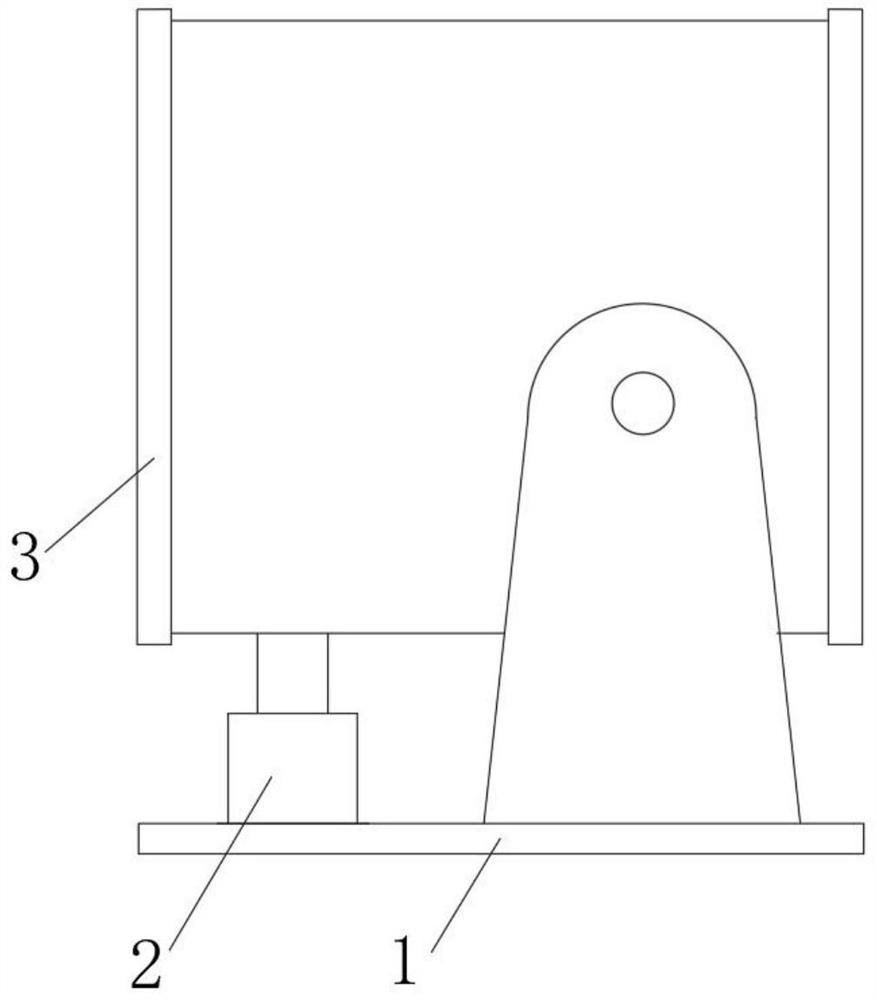

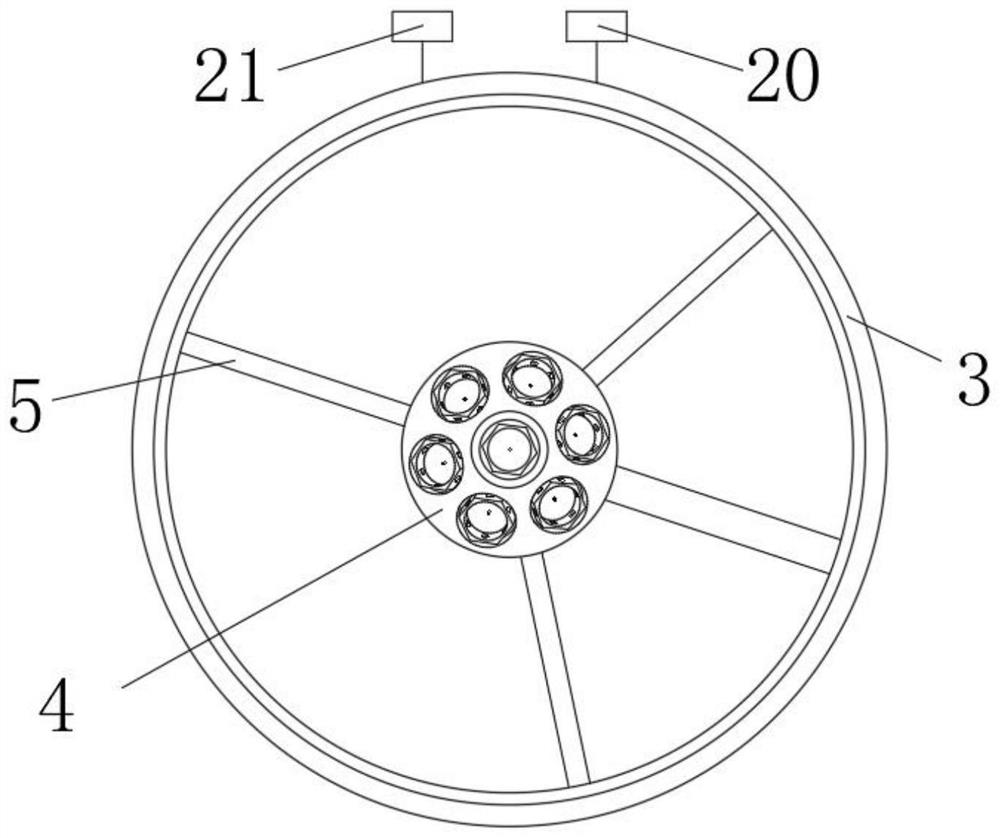

[0043] like Figure 1-6 shown. The present invention provides an intelligent water source powered shearer dust collector comprising a base 1, a hydraulic jack 2, a spray air duct 3, a multi-angle combined spray group 4, a fixed frame 5, a rotary spray group 6, a magnetizer 7, an impeller 8, Fixed plate 9, driving device 10, annular spray group 11, main water inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com