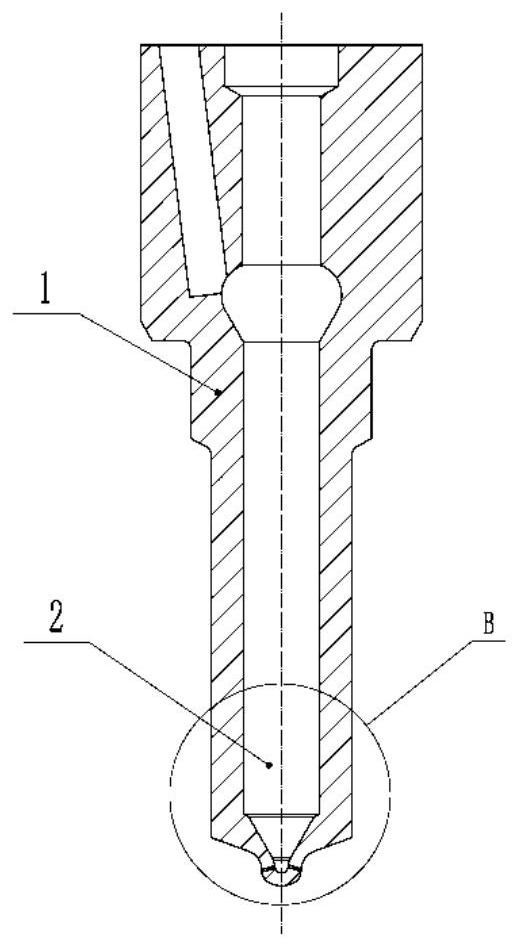

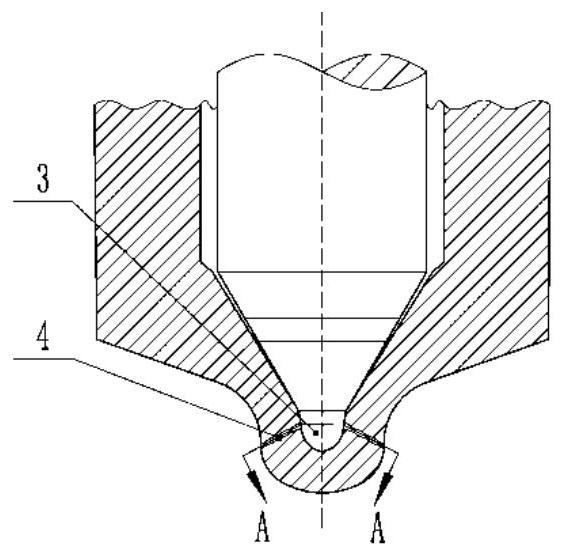

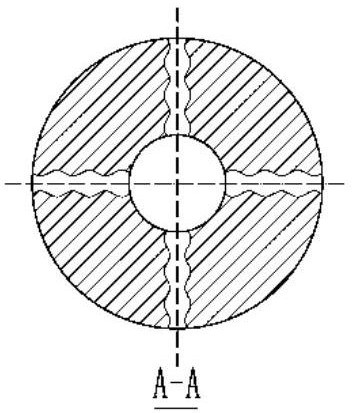

High-strength diesel engine swirl nozzle

A diesel engine and nozzle technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of inability to meet the requirements of high-strength engines, incomplete fuel combustion, low combustion efficiency, etc., to improve power performance and enhance entrainment. ability, the effect of improving the heat transfer ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0036] At present, there are various methods to increase the cavitation intensity and atomization quality of fuel injected by diesel injectors. The technology is mature and mass production has been achieved, such as reducing the diameter of the nozzle or controlling the fuel injection volume, injection pressure and injection time through the electrical system. . However, the above-mentioned common methods cannot be directly applied to high-strength engines, because the high-temperature and high-pressure environment hinders the further development of the spray, causing the initial near-field spray to collapse. On this basis, the present invention does not increase the fuel flow velocity by adding a baffle in the needle valve, but enhances the entrainment effect of the jet by changing the traditional nozzle structure, specifically, through the helical struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com