Cavitation-preventing device for condensate pump

A technology for anti-cavitation and water pumps, which is applied to components, pumps, and pump components of elastic fluid pumping devices, and can solve problems such as damage to impellers, high civil construction costs, and limited transformation capabilities of circulating water systems. Reduce the inlet water temperature, improve cavitation conditions, effective and reliable cavitation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

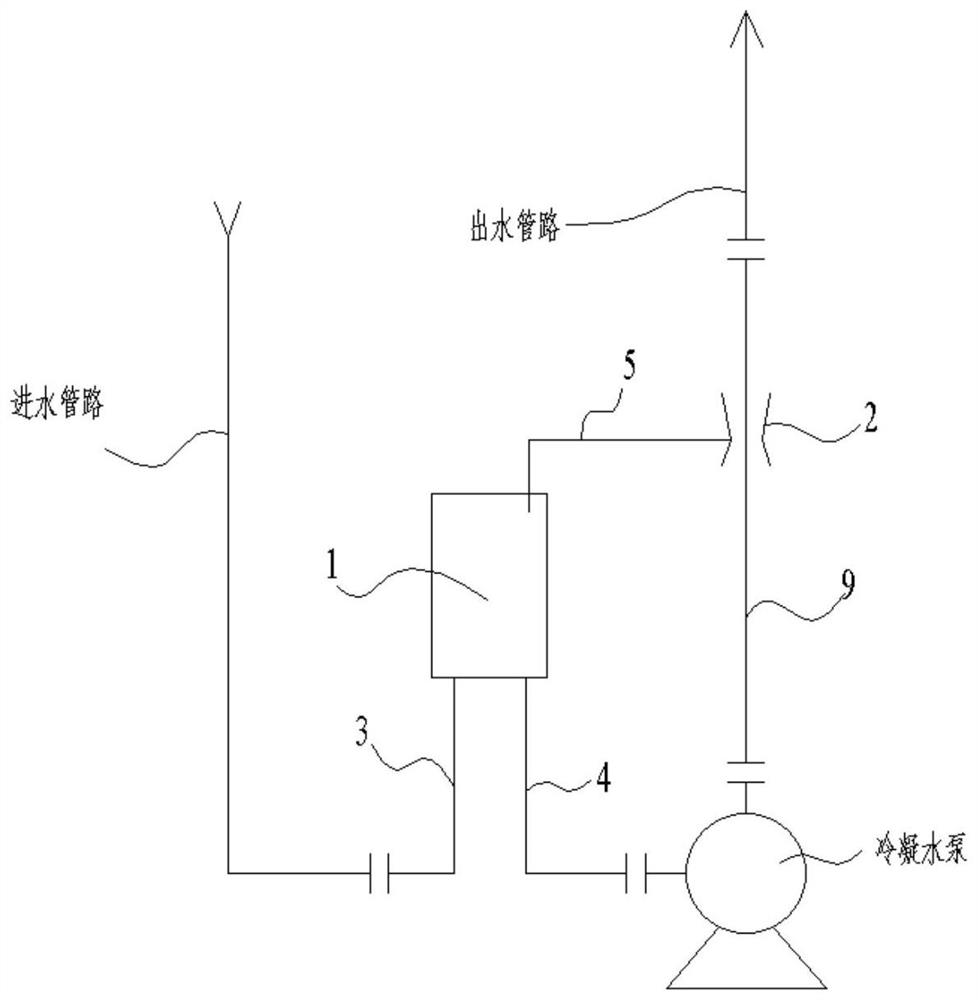

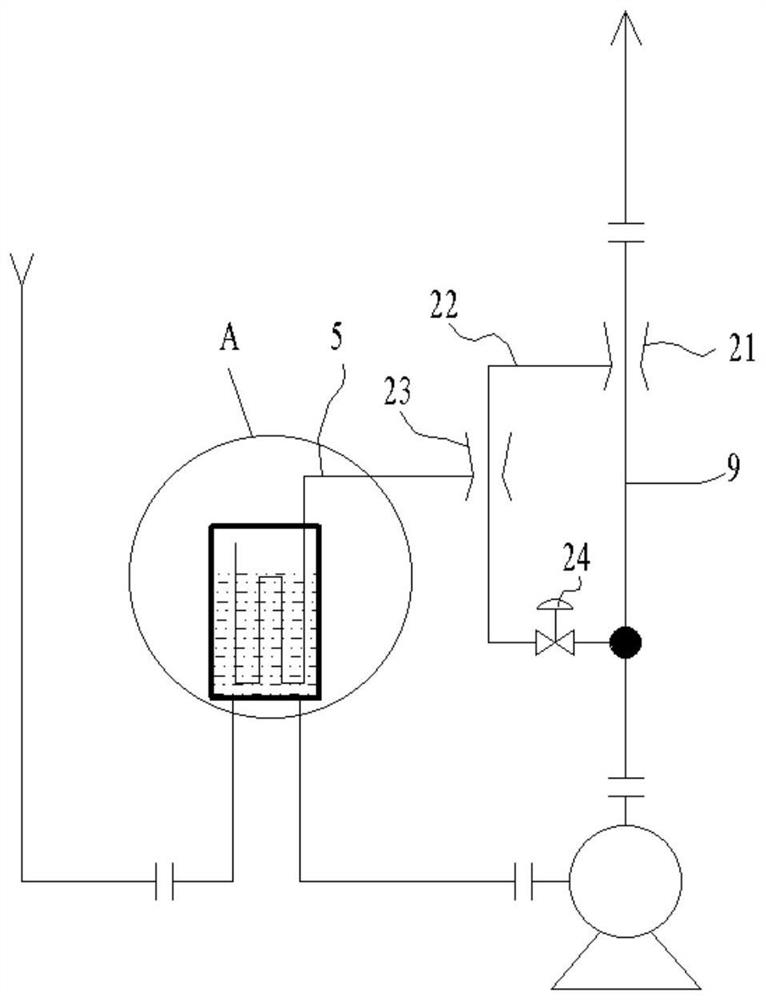

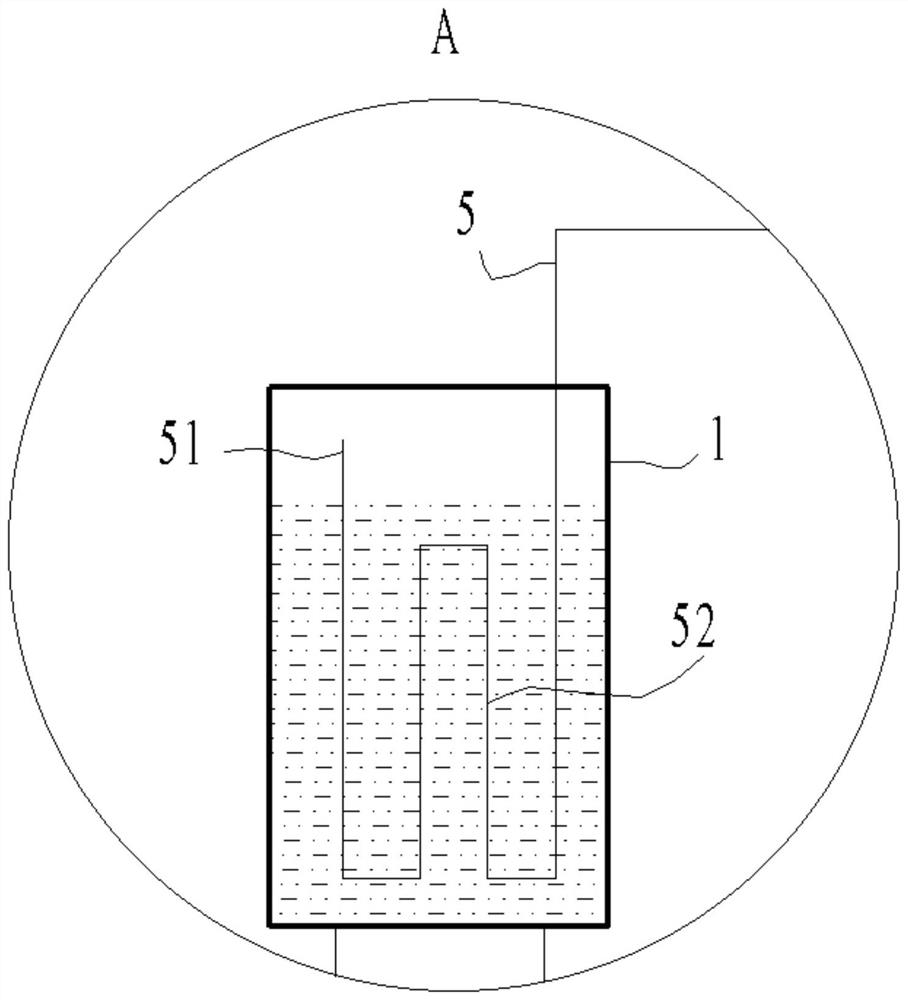

[0025] see Figure 1-3 ,

[0026] The anti-cavitation device of the condensate pump is installed between the condensate pump, the water inlet pipeline and the water outlet pipeline. The outlet pipe 9, the gas-liquid separation assembly is connected to the water inlet pipe through the inlet pipe 3, the gas-liquid separation assembly is connected to the inlet of the condensate pump through the outlet pipe 4, and the pump outlet pipe 9 is connected to the outlet of the condensate pump and the outlet pipe, and the pump outlet pipe 9 is set The drainage component 2 and the gas-liquid separation component are connected to the drainage component 2 through the air outlet pipe 5, and the installation height of the gas-liquid separation component is higher than the water inlet of the condensate pump. The cavitation at the water inlet of the condensate pump is caused by the vaporization of water. The condition of vaporization is an increase in temperature or a decrease in pressure. Most...

specific Embodiment approach 2

[0033] The separation tank 1 in the specific embodiment one is replaced by a separation cylinder 6, for details see Figure 4~6 :

[0034] The gas-liquid separation component is a separation cylinder 6. The separation cylinder 6 includes a cylinder body 61, a spiral blade 62, and an air induction pipe 63. The top of the cylinder body 61 is connected to the inlet pipe 3, and the bottom of the cylinder body 61 is connected to the liquid outlet pipe 4. The upper part of the cylinder body 61 is A fixed helical blade 62 is provided, and the helical blade 62 directs the flow of the working medium flowing through it into a spiral descent. One end of the air-inducing pipe 63 is set inside the cylinder body 61, and the other end passes through the side wall of the cylinder body 61 and connects to the air outlet pipe 5 outward. The vertical part of the air pipe 63 inside the cylinder body 61 is coaxial with the cylinder body 61 , and the air induction pipe 63 is located below the helica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com