Miniature shaft roller driving mechanism

A driving mechanism and micro shaft technology, applied in electromechanical devices, mechanical equipment, electric components, etc., can solve the problems of low precision and large volume, and achieve the effect of high rotation precision of the roller, precise control of rotation and stop angle, and simple assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

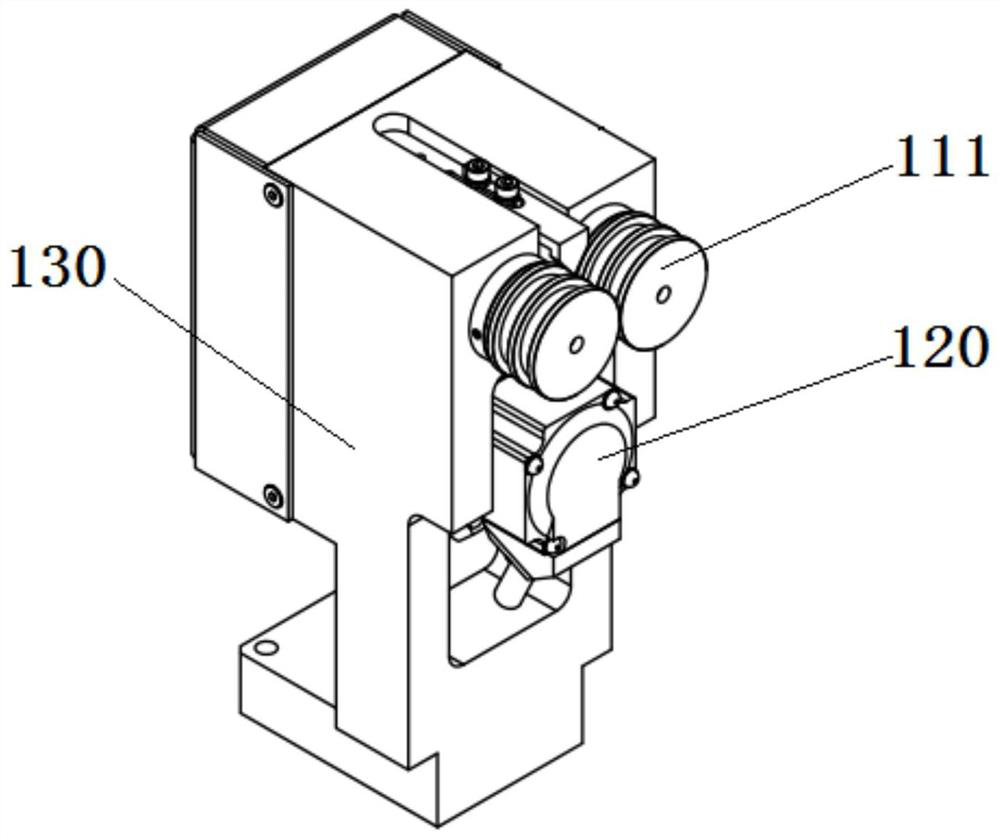

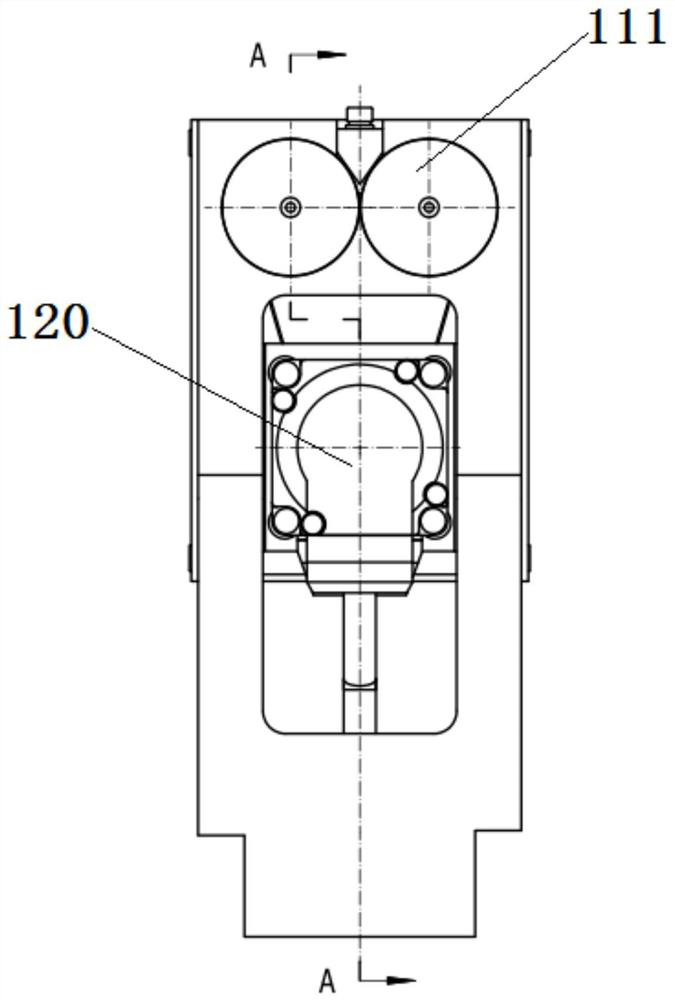

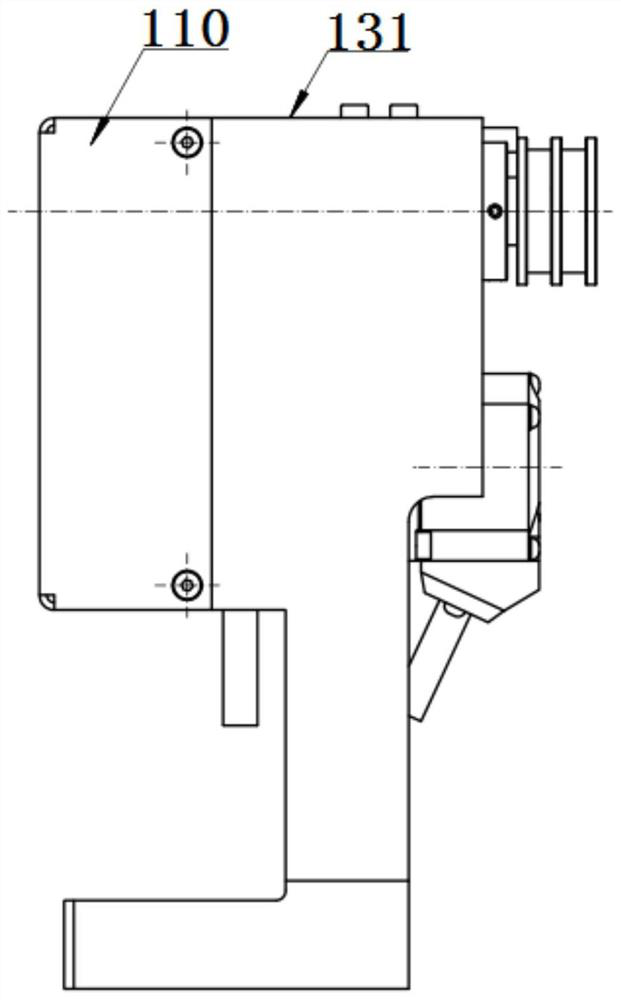

[0045] like Figure 1-7 As shown, the present invention provides a miniature shaft roller driving mechanism, including: a main shaft 110, a second pulley 111, a first lock nut 112, a first bearing 113, a sleeve 114, a first bushing 115, and a key 116 , the second shaft sleeve 117 , the second locking nut 118 , the second bearing 119 , the drive motor 120 , the first pulley 121 , the conveyor belt 122 , and the bracket 130 .

[0046] like figure 1 , Figure 5 As shown, the driving motor 120 is supported and arranged in the middle of the bracket 130, the first pulley 121 is connected to the output end of the driving motor 120, the two rotating mechanisms are arranged symmetrically, and one end of the rotating mechanism passes through and is rotatably supported on the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com