Electric compactor

A compactor and electric technology, used in instruments, scientific instruments, sampling, etc., can solve the problems of high compaction, affecting test accuracy, uneven sample hammering, etc., and achieve the effect of simple structure and simple control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

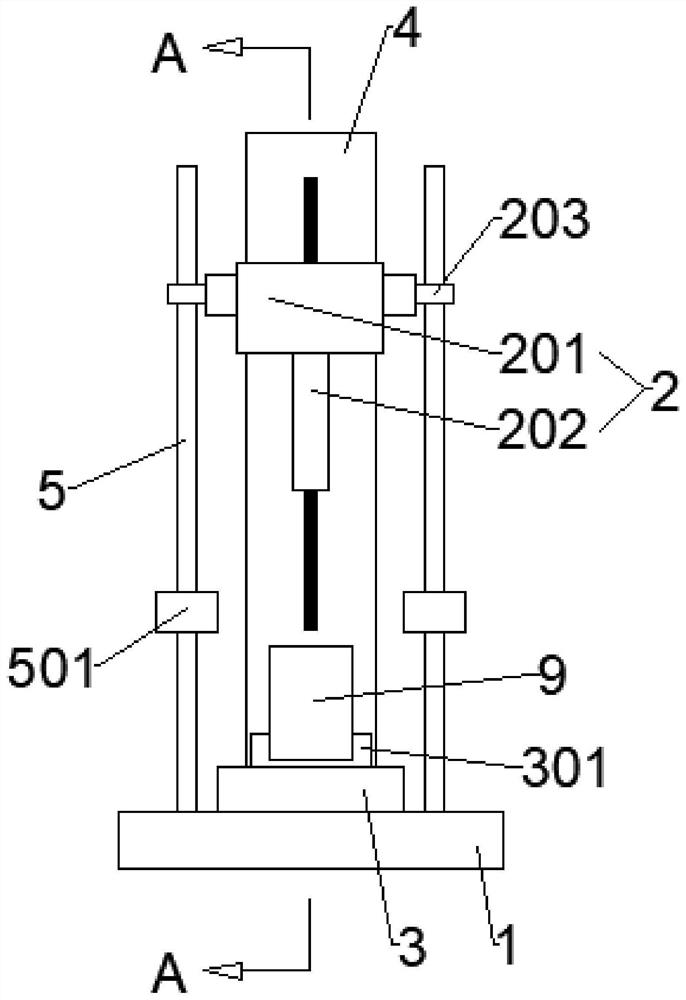

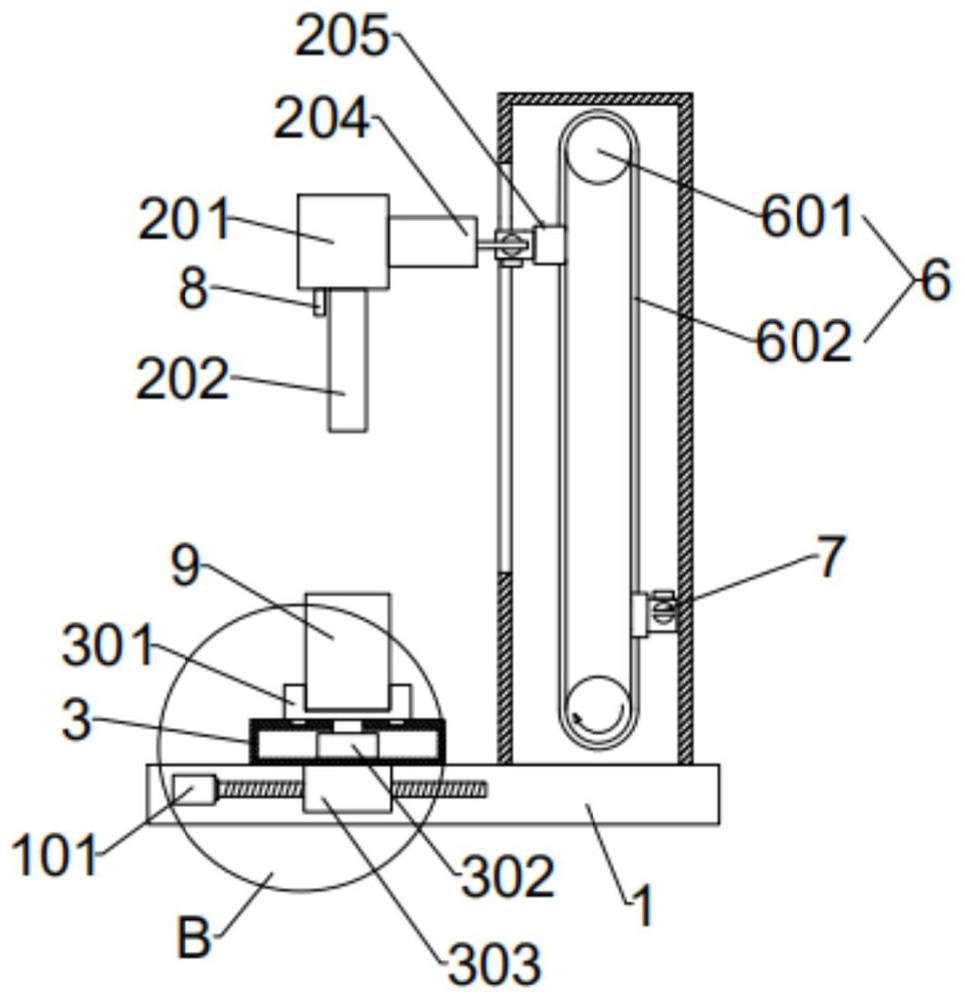

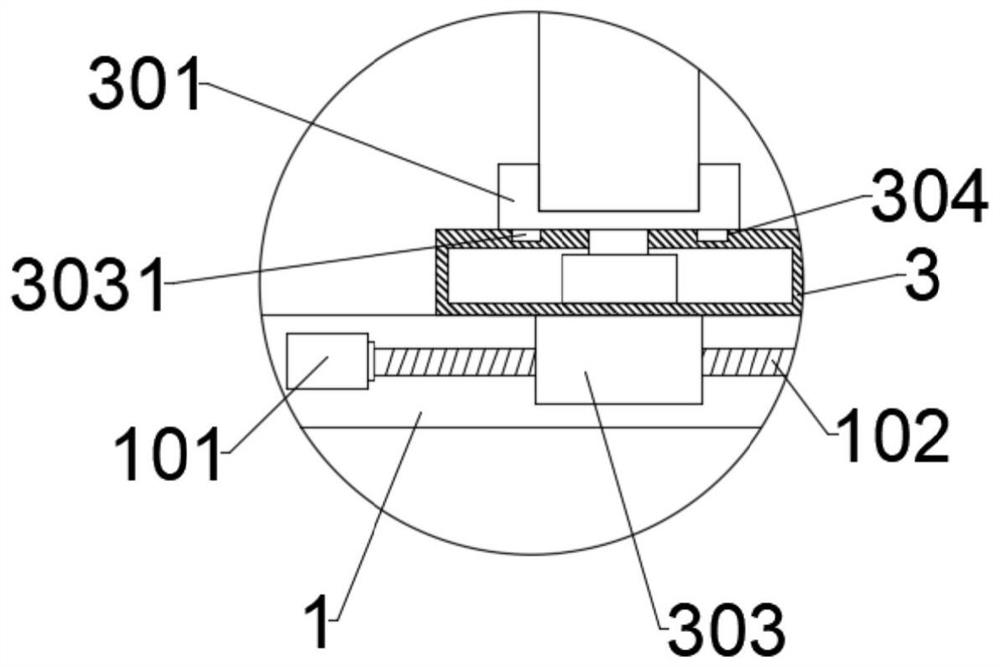

[0039] Such as Figure 1-3 As shown, an electric compaction instrument includes a base 1 and a compaction hammer 2. The base 1 is provided with a rotating base 3 and a lifting base 4. The rotating base 3 is provided with a placing table 301 for placing the test cylinder 9. The lower surface of the table 301 is connected to the driving end of the first rotating motor 302 which is arranged inside the rotating base 3 and can drive it to perform intermittent rotating motions in the horizontal plane;

[0040] Also be provided with two vertically arranged guide pillars 5, the guide pillars 5 are respectively located on the left and right sides of the rotating seat 3; The sliding seat 201 is fixedly connected, and the left and right sides of the sliding seat 201 are respectively connected with a sliding ring 203, and the sliding ring 203 is connected with the guide column 5 slidingly up and down; the inside of the lifting seat 4 is provided with a chain transmission mechanism 6, and ...

Embodiment 2

[0052] An electric compaction instrument, comprising a base 1 and a compaction hammer 2, the base 1 is provided with a rotating base 3 and a lifting base 4, the rotating base 3 is provided with a placement table 301 for placing a mold test cylinder 9, and the placement table 301 The lower surface is connected to the driving end of the first rotating motor 302 which is arranged inside the rotating seat 3 and can drive it to perform intermittent rotating motion in the horizontal plane;

[0053] Also be provided with two vertically arranged guide pillars 5, the guide pillars 5 are respectively located on the left and right sides of the rotating seat 3; The sliding seat 201 is fixedly connected, and the left and right sides of the sliding seat 201 are respectively connected with a sliding ring 203, and the sliding ring 203 is connected with the guide column 5 slidingly up and down; the inside of the lifting seat 4 is provided with a chain transmission mechanism 6, and the chain tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com